Zinc sulfide nano particle with sulfydryl surface finish and preparation method thereof

A nanoparticle and surface modification technology, applied in nanotechnology, zinc sulfide, nanotechnology, etc. for materials and surface science, can solve the problems of high activity of hydroxyl and carboxyl groups, lower refractive index, abrupt interface changes, etc., to achieve enhanced Dispersibility, improved bonding, and increased refractive index effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add 0.81g of zinc acetate dihydrate to 50ml of dimethylformamide and mix well, then put it into a three-necked flask and stir it with nitrogen; then add a premix of 1.145g of BES and 25ml of dimethylformamide to the three-necked flask After stirring for 20 minutes, the temperature was raised to 120°C, a premixture of 0.28g thiourea and 25ml dimethylformamide was added, and the mixture was refluxed at 120°C for 10 hours. Then use a vacuum pump to distill and concentrate the reaction product under reduced pressure, precipitate the concentrated solution with ethanol, centrifuge the obtained zinc sulfide particles, wash 3 times with ethanol, wash 2 times with methanol, and dry in vacuum to obtain white powdery zinc sulfide nanoparticles. In this implementation, zinc source / sulfur source / modifier thiol=1 / 1 / 3 (molar ratio).

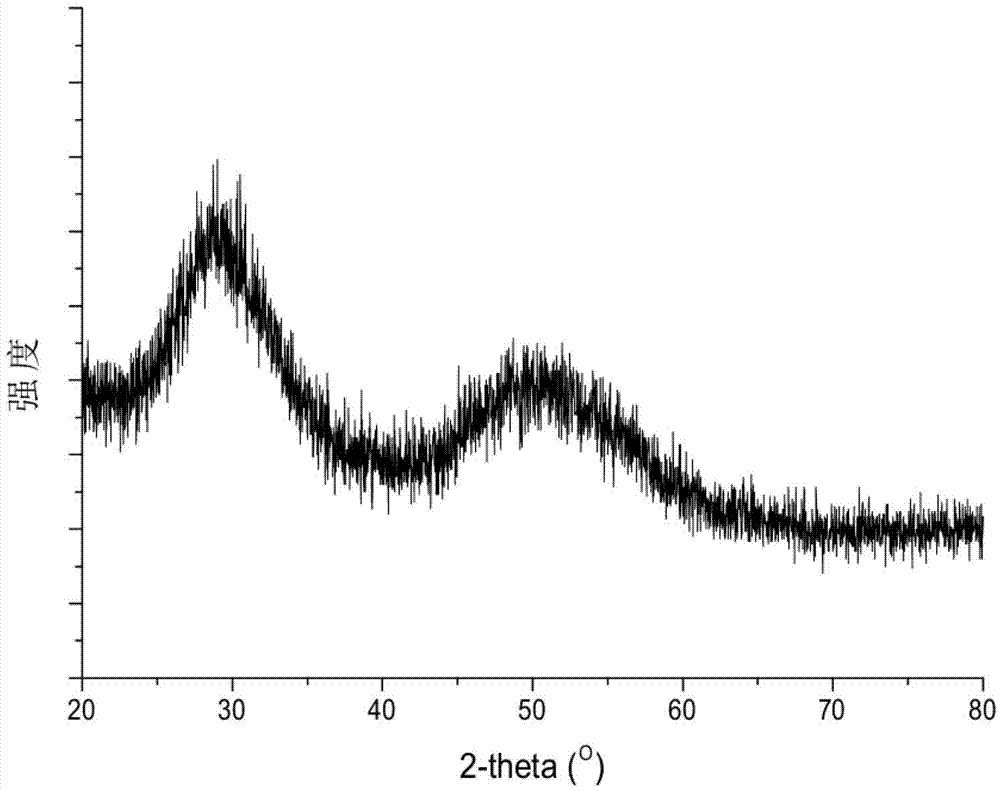

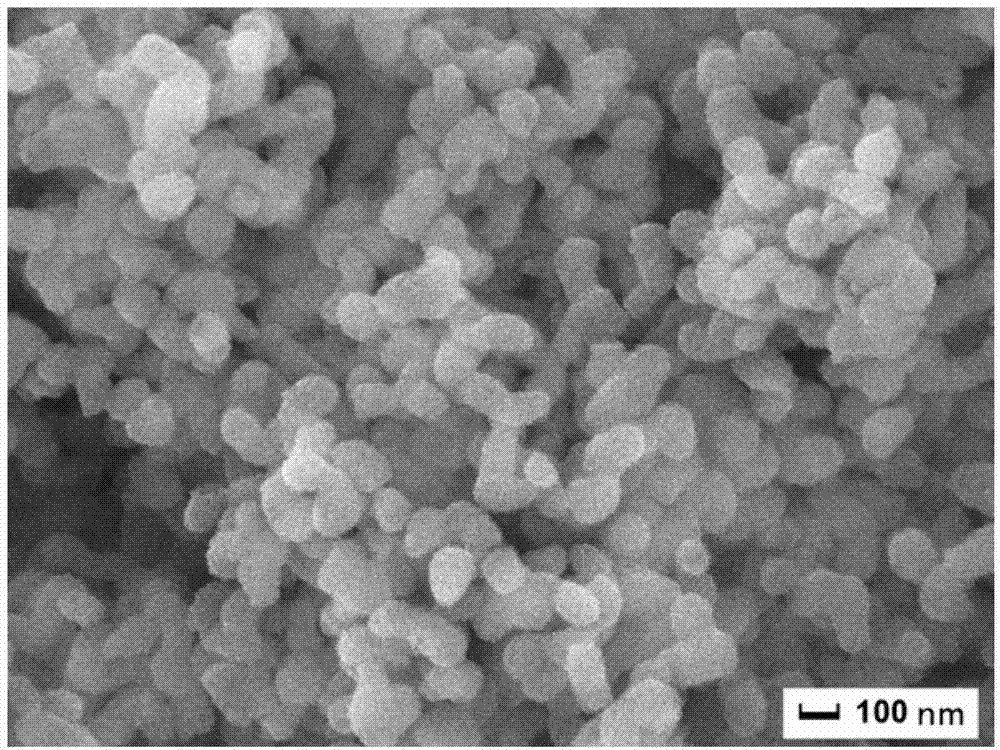

[0028] Prepare the resulting product by this embodiment, its X-ray diffraction analysis is as follows: figure 1 As shown, the abscissa angle in the fi...

Embodiment 2

[0030] Add 0.81g of zinc acetate dihydrate to 50ml of dimethylformamide, mix well, put it into a three-necked flask and stir with nitrogen; then add a premixture of 1.145g of BES and 25ml of dimethylformamide to the three-necked flask After stirring for 20 minutes, the temperature was raised to 150°C, a premixture of 0.28g thiourea and 25ml dimethylformamide was added, and the mixture was refluxed at 120°C for 10 hours. Then use a vacuum pump to distill and concentrate the reaction product under reduced pressure, precipitate the concentrated solution with ethanol, centrifuge the obtained zinc sulfide particles, wash 3 times with ethanol, wash 2 times with methanol, and dry in vacuum to obtain white powdery zinc sulfide nanoparticles. In this example, zinc source / sulfur source / modifier thiol=1 / 1 / 3 (molar ratio). The zinc sulfide nanoparticles prepared in this example have the same structure as the microspheres prepared in Example 1, and have the same excellent performance.

Embodiment 3

[0032] Add 0.81g of zinc acetate dihydrate to 50ml of dimethylformamide, mix well, put it into a three-necked flask and stir with nitrogen; then add a premixture of 1.145g of BES and 25ml of dimethylformamide to the three-necked flask After stirring for 20 minutes, the temperature was raised to 150°C, a premixture of 0.558g thiourea and 25ml dimethylformamide was added, and the mixture was refluxed at 120°C for 8 hours. Then use a vacuum pump to distill and concentrate the reaction product under reduced pressure, precipitate the concentrated solution with ethanol, centrifuge the obtained zinc sulfide particles, wash 3 times with ethanol, wash 2 times with methanol, and dry in vacuum to obtain white powdery zinc sulfide nanoparticles. In this example, zinc source / sulfur source / modifier thiol=1 / 2 / 3 (molar ratio). The zinc sulfide nanoparticles prepared in this example have the same structure as the microspheres prepared in Example 1, and have the same excellent performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com