Hot-air drying processing technique of pet food

A technology of hot air drying and processing technology, which is applied in the direction of static material dryer, drying solid material, drying gas arrangement, etc., which can solve labor cost, water and electricity cost, heat energy cost increase, unavoidable air cross-contamination, long processing process, etc. problems, to achieve the effect of reducing investment in fixed assets, eliminating the need for high-pressure sterilization processes, and shortening the processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

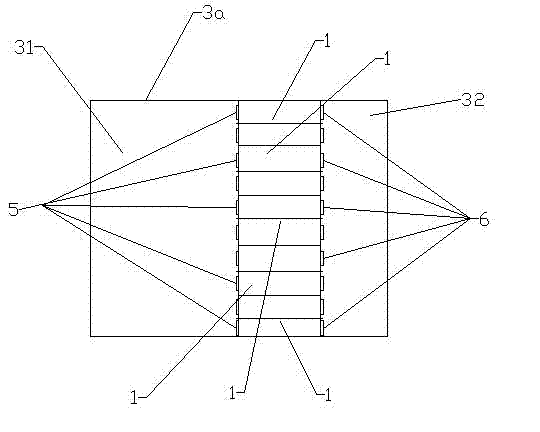

[0046] Embodiment 1, a pet food hot air drying processing method, the preparation method includes the following steps: as figure 1 As shown, at first 10 drying rooms 1 are installed in the working workshop 3a, and the working workshop 3a utilizes 10 drying rooms 1 to separate and divide the positions between the feeding door 5 and the discharging door 6 into independent, closed and disconnected parts. Raw area 31 and cooked area 32.

[0047] In the raw material area 31 in the workshop 3a at one end of the feed door 5, the raw meat that has passed the acceptance check is thawed, batched, rolled, and then formed into a semi-finished product for later use;

[0048] Arrangement: place the formed semi-finished products evenly on the grid tray, and put the filled grid tray on the rack; hot air drying: close the discharge door 6 of the drying room, and then open the feed door 5, and put the semi-finished products Push the shelf car into the drying room 1, close the feed door 5, and ...

Embodiment 2

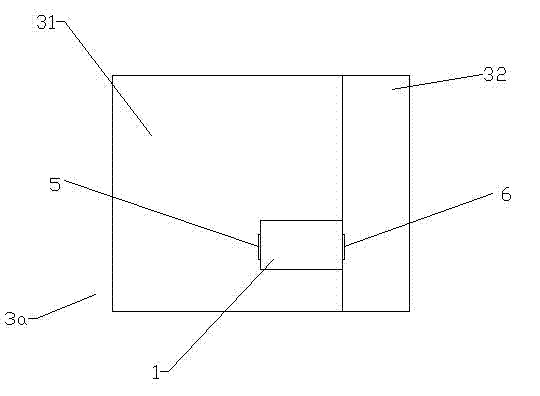

[0056] Example 2, such as figure 2 As shown, a drying room 1 is installed in the working workshop 3a, and the working workshop 3a is divided into a raw area 31 and a cooked area 32 which are independently closed and not connected at the position between the charging door 5 and the discharging door 6.

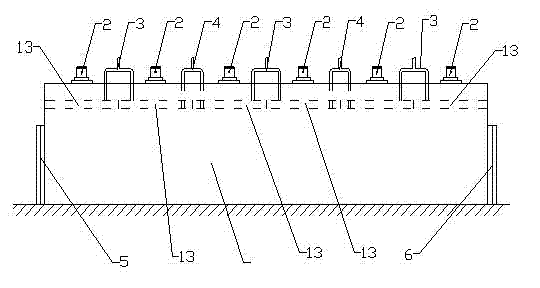

[0057] Such as Figure 4 As shown, the top of the drying room 1 is provided with six motors 2, and the bottom of each motor 2 is combined with the attached Figure 8 Shown all is connected with the heat dissipation device that wind impeller 11 and radiator 15 are formed, and each heat dissipation device is all positioned in air inlet channel 13, and air inlet channel 13 is provided with the air inlet channel 3 that communicates with air inlet channel 13, and drying room 1 There are two exhaust pipes 4 connected to the drying channel above the top of the oven, and each exhaust pipe 4 has two pipe branches to communicate with the drying channel. The two ends of the drying room 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com