Surface-treated calcium carbonate and paste-like resin composition containing same

一种表面处理、糊状树脂的技术,应用在碳酸钙/锶/钡、钙/锶/钡化合物、染色低分子有机化合物处理等方向,能够解决高触变性、难以赋予高粘度、固化物机械物性和粘合性差等问题,达到高触变性、良好机械物性和粘合性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

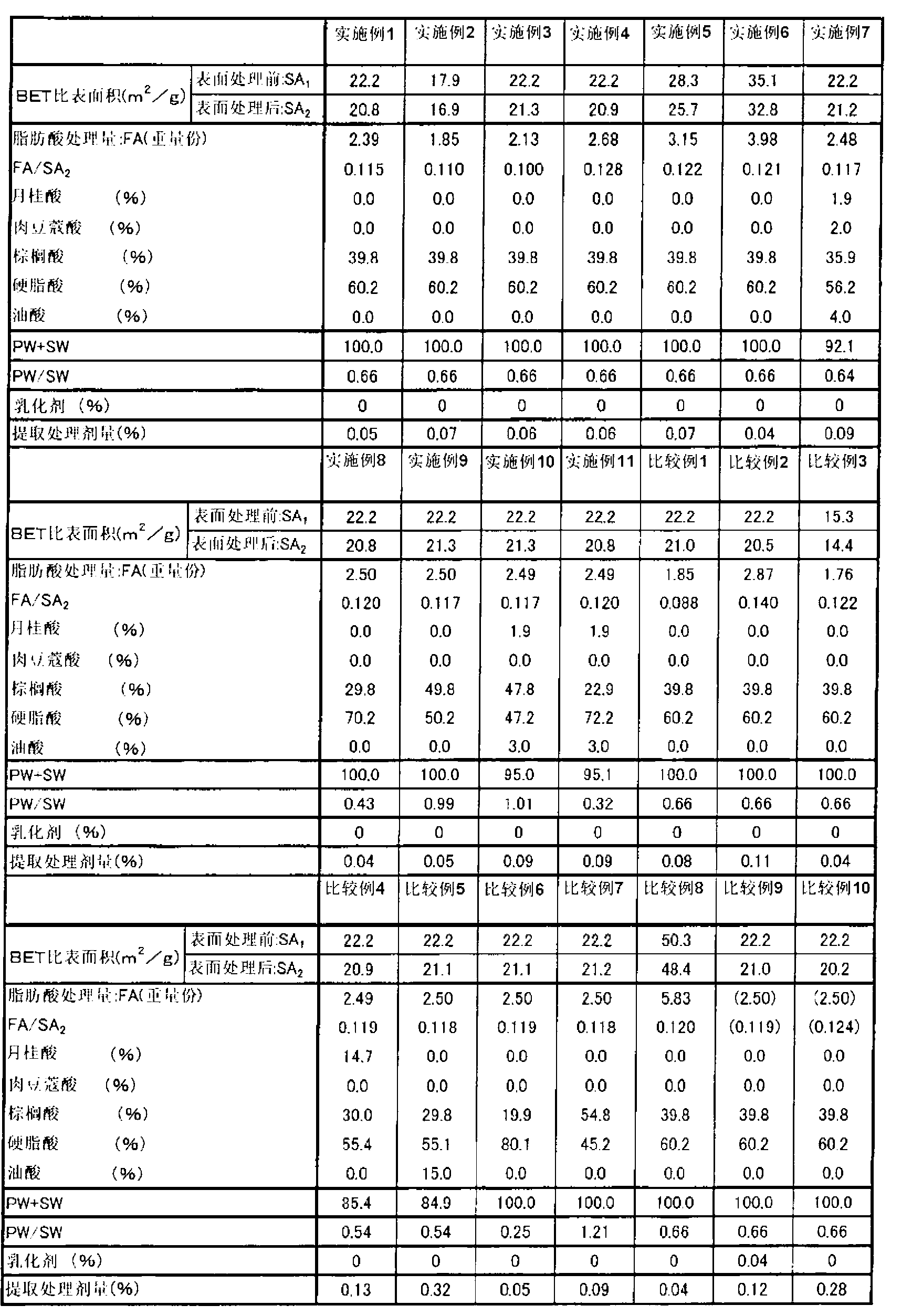

Embodiment 1)

[0100] In 2kg BET specific surface area is 22.2m 2 / g of synthetic calcium carbonate, water adjusted to 60°C was added so that the solid content was 10% by weight, and a calcium carbonate slurry was prepared using a stirring type disperser. While stirring this slurry with a disperser, add 54g mixed fatty acid sodium salts (in acid conversion, 19.9g palmitic acid, 27.9 g stearic acid), after stirring for 5 minutes, press and dehydrate.

[0101] After drying the obtained dehydrated cake, about 2 kg of surface-treated calcium carbonate was obtained by powdering.

Embodiment 2)

[0103] Use BET specific surface area of 17.9m 2 / g of synthetic calcium carbonate, add 40g of mixed fatty acid sodium salts (in terms of acid conversion, 14.7g of palmitic acid, 22.3g of stearic acid) mixed with 16g of sodium palmitate and 24g of sodium stearate, in addition, with Above-mentioned embodiment 1 operates similarly, obtains surface-treated calcium carbonate.

Embodiment 3)

[0105] Except adding 46 g of mixed fatty acid sodium salts mixed with 18.4 g of sodium palmitate and 27.6 g of sodium stearate (in terms of acid conversion, 16.9 g of palmitic acid and 25.6 g of stearic acid), the same operation was performed as in Example 1 above, Get surface treated calcium carbonate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com