Agent for maintaining surface temperature of molten steel and method for maintaining surface temperature of molten steel

A technology of heat preservation agent and surface temperature, applied in the field of molten steel surface heat preservation agent, which can solve problems such as the increase of surface defects of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

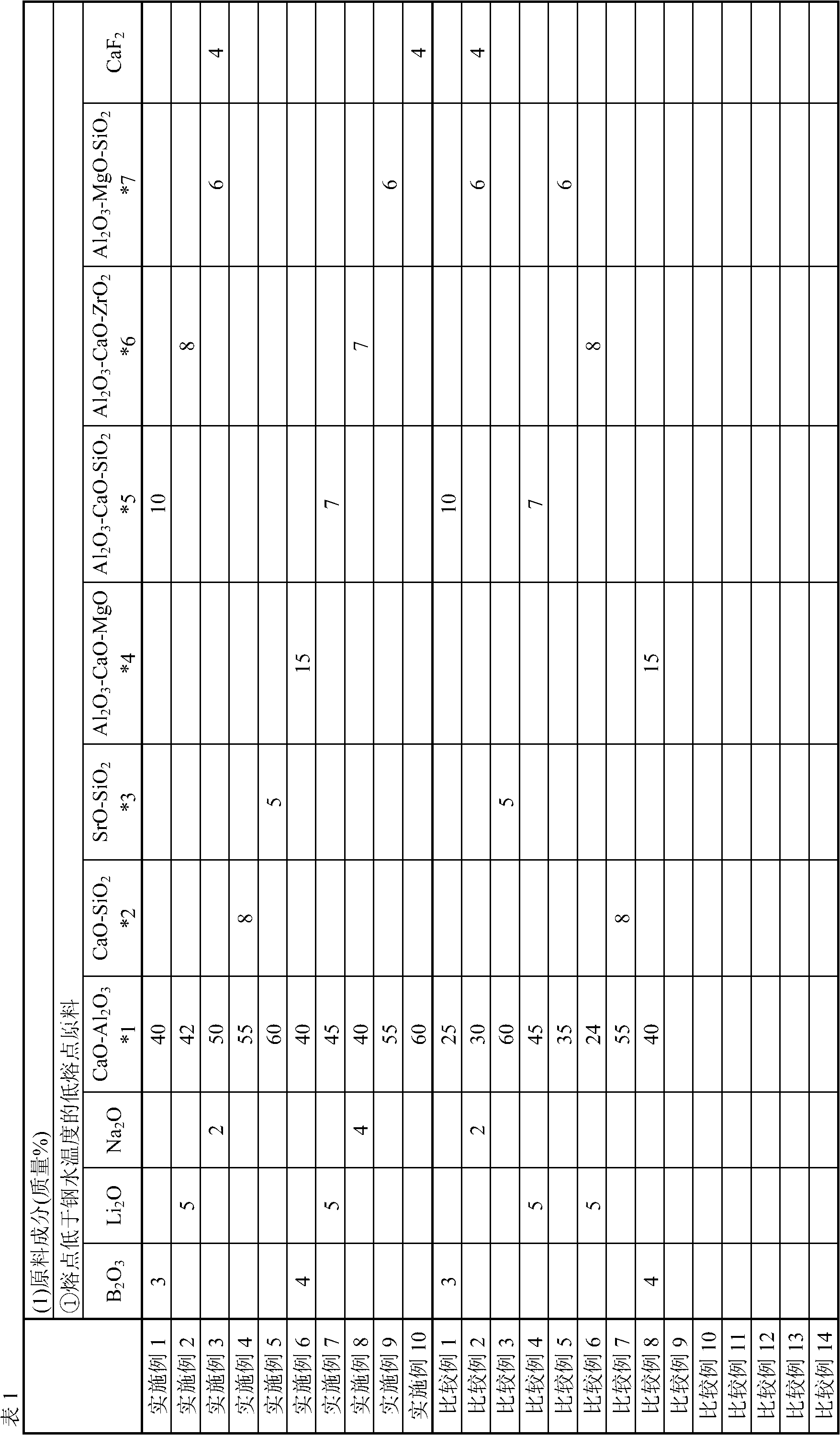

[0031] Hereinafter, the present invention will be described based on examples, but the conditions of the examples are examples of conditions adopted to confirm the possibility and effect of the present invention, and the present invention is not limited to these example conditions.

[0032] As long as the present invention does not deviate from the purpose of the present invention and can achieve the object of the present invention, various conditions and even combinations of conditions can be adopted.

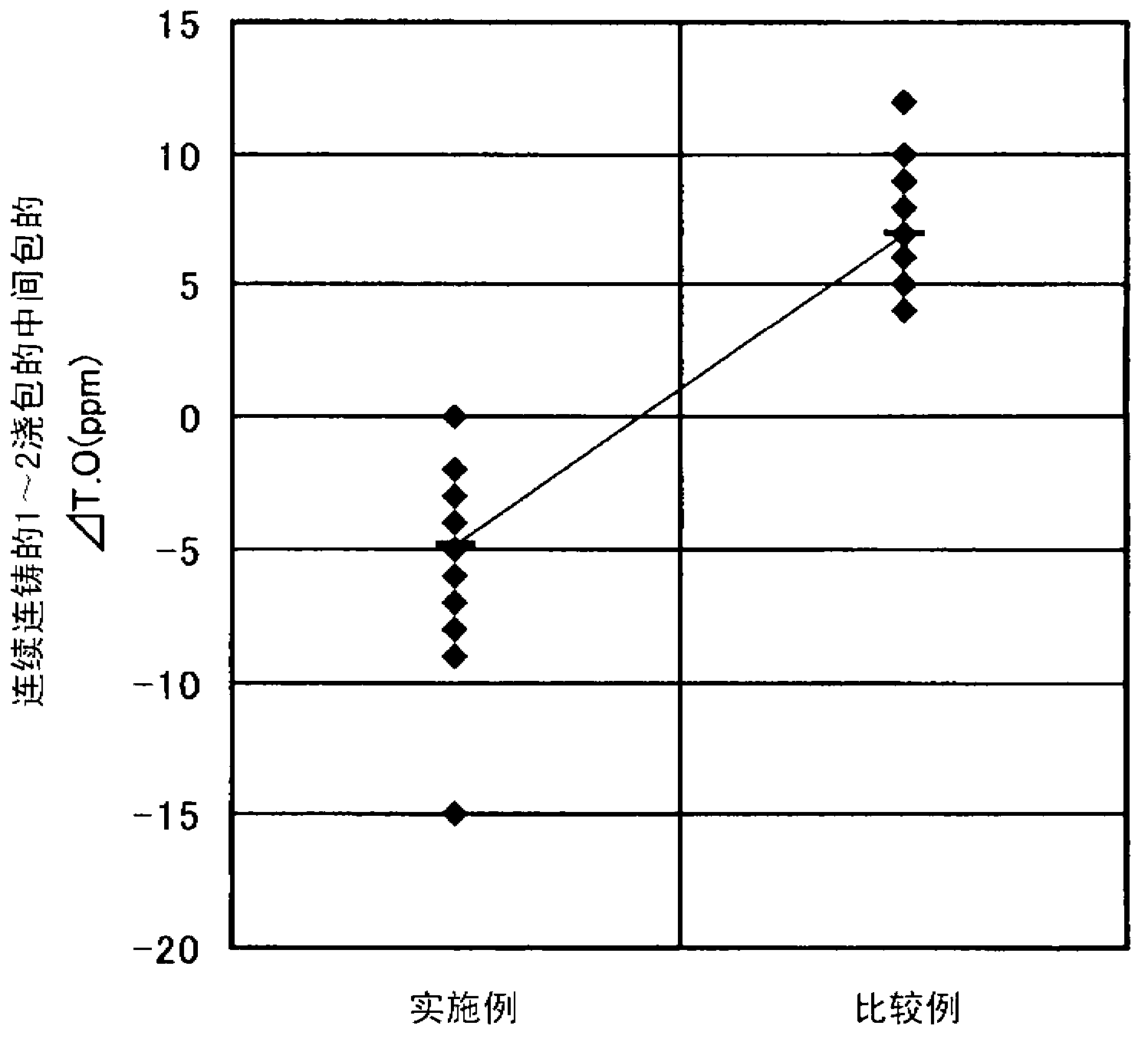

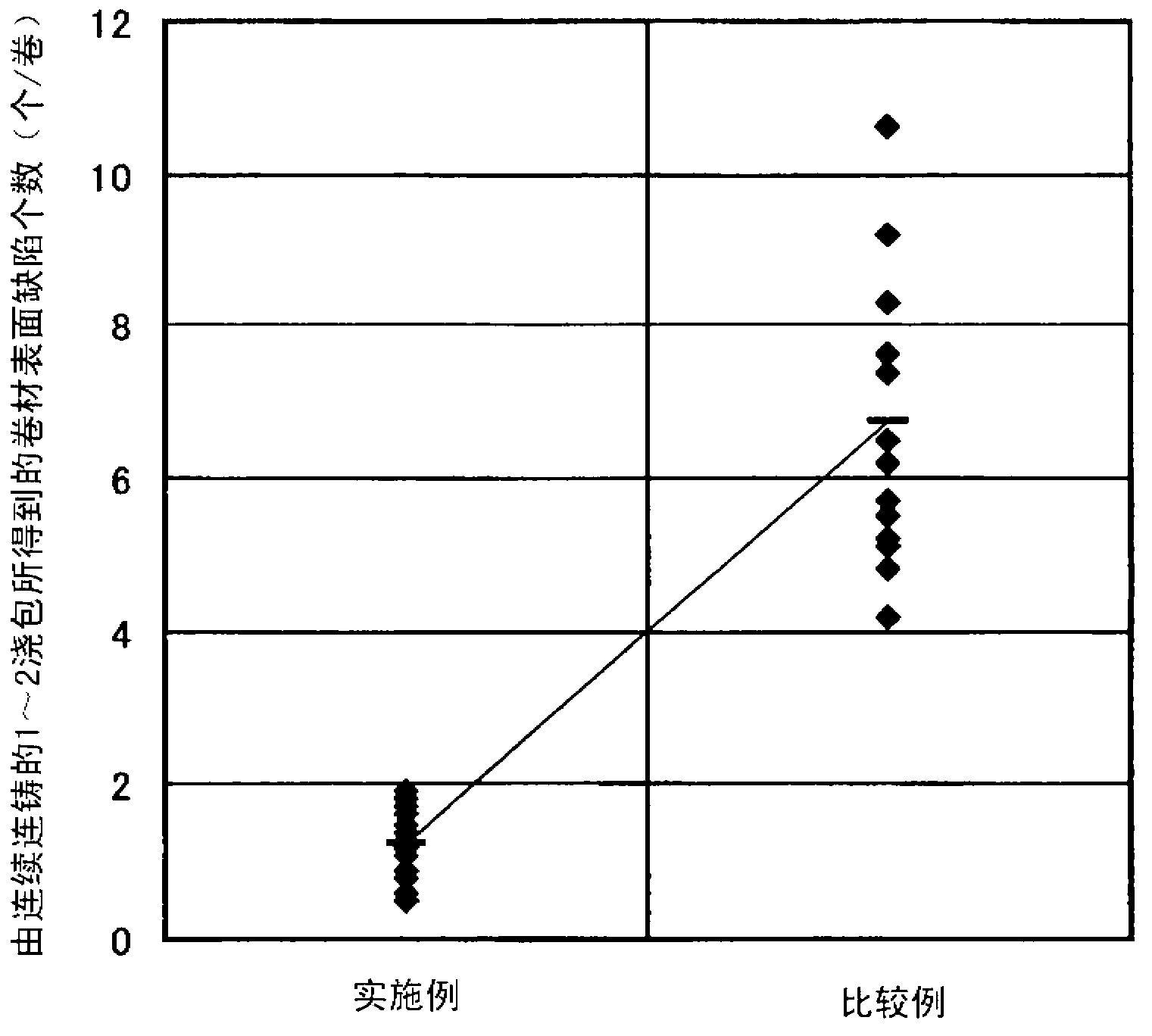

[0033] The molten steel with a filling volume of 280t is subjected to molten iron pretreatment, converter decarbonization, and RH vacuum degassing treatment to smelt extremely low carbon steel. A tundish with a capacity of 60t is used to produce cast slabs by continuous casting. Continuous casting of molten steel with 15 fillings. The surface temperature of molten steel is set to 1560 to 1580°C. The surface insulation agent for molten steel of the present invention or comparative...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com