Direct feed omnidirectional printed antenna with radiation load

A printed antenna and radiation type technology, which is applied in the direction of antenna, antenna array, radiating element structure, etc., can solve the problems of wide bandwidth, omnidirectional antenna can not meet the requirements of good omnidirectionality and high gain at the same time, and reduce the out-of-roundness of the pattern , simple structure and compact feed form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

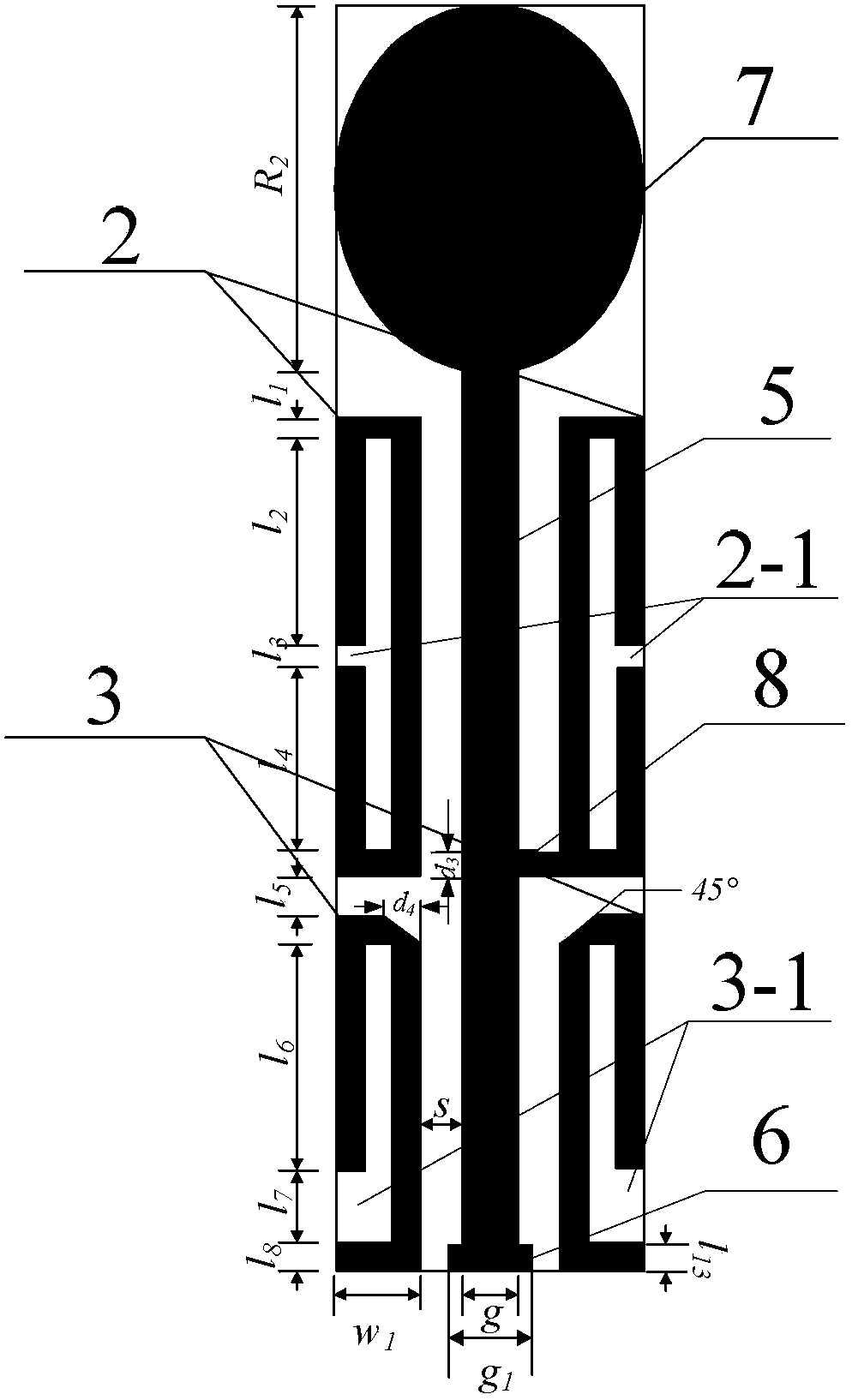

[0008] Specific implementation mode one: combine Figure 1-Figure 10 Describe this embodiment, the antenna of this embodiment includes a dielectric plate 1 and a coplanar waveguide central feeder 5, and the antenna also includes two groups of vibrators, a feeding port matching branch 6, a radial terminal load 7, a first horizontal feeder 8, The second horizontal feeder 9 and the third horizontal feeder 10, two groups of oscillators, the coplanar waveguide central feeder 5, the feeding port matching branch 6, the radial terminal load 7 and the first horizontal feeder 8 are printed on the front side wall of the dielectric board 1 , the second horizontal feeder 9 and the third horizontal feeder 10 on the rear side wall of the dielectric board 1, the lower end of the coplanar waveguide central feeder 5 is connected to the feeding port matching stub 6, the upper end of the coplanar waveguide central feeder 5 is connected to the radial terminal The load 7 is connected, and each grou...

specific Embodiment approach 2

[0013] Specific implementation mode two: in conjunction with figure description 1- Figure 10 To illustrate this embodiment, the radial terminal load 7 of this embodiment is elliptical, isosceles trapezoidal or combined, wherein the combined shape is composed of a rectangle and a semicircle, and the short side of the rectangle coincides with the diameter of the semicircle. The terminal radiation load is an elliptical load, which plays a role that ordinary loads do not have, that is, radiates electromagnetic waves, so that the gain of the antenna is further improved. The semicircular and coplanar waveguide center feeders in the combined load realize gradual transition; the load of the trapezoidal load antenna adopts an isosceles trapezoid to ensure symmetry. Other implementation manners are the same as the specific implementation manner 1.

specific Embodiment approach 3

[0014] Specific implementation mode three: in conjunction with figure description 1 and Figure 7 To illustrate this embodiment, a 45° isosceles right triangle is cut off at the apex position of each second vibrator 3 close to the coplanar waveguide center feeder 5 in this embodiment, and cutting the isosceles right triangle can reduce the antenna feeder. reflection to achieve better matching, other implementations are the same as the first implementation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com