Method for obtaining tri-state tissue from titanium alloy

A titanium alloy and microstructure technology, applied in the field of heat treatment to obtain three-state microstructure, can solve the problems of complex forging control and high local temperature of forgings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

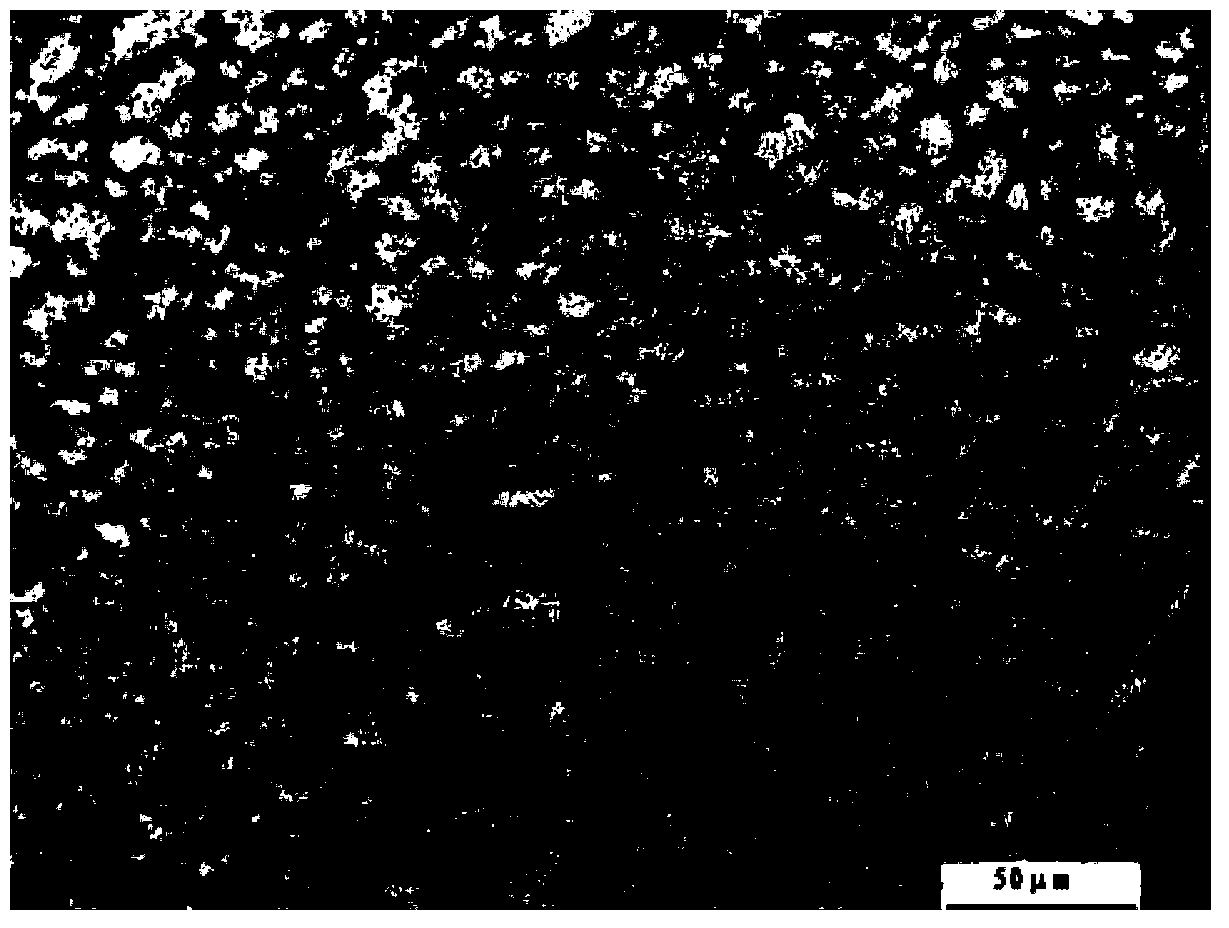

[0019] This embodiment is a method for obtaining a three-state structure in a titanium alloy. The sample used is a TA15 titanium alloy. The shape of the sample is cylindrical, and the specification of the sample is Φ10*15mm; the TA15 titanium alloy is Ti -6Al-2Zr-1Mo-1V. The β transformation point of TA15 titanium alloy is 990°C, and the initial structure is equiaxed.

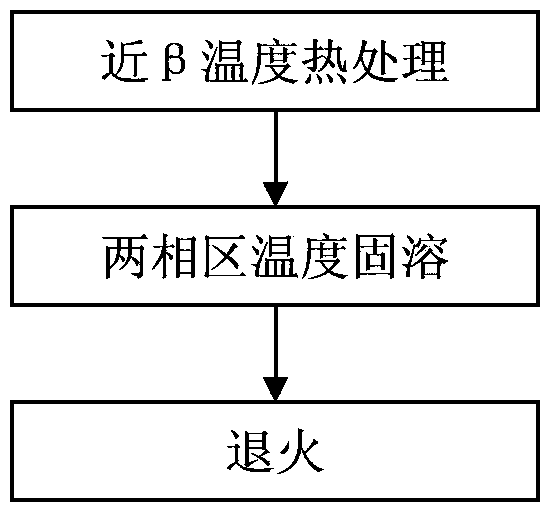

[0020] The specific implementation steps of this embodiment are:

[0021] Step 1, heat treatment near β temperature. The resistance furnace is heated to the near β temperature of the TA15 titanium alloy, that is, the temperature range is 10-20°C lower than the β transformation point. In this embodiment, the temperature of the resistance furnace is 975°C, which is 15°C lower than the β temperature of the TA15 titanium alloy. When the temperature of the resistance furnace reaches 975°C, put the cylindrical sample into the resistance furnace. Heat the resistance furnace to 975°C and start heat preservation. The...

Embodiment 2

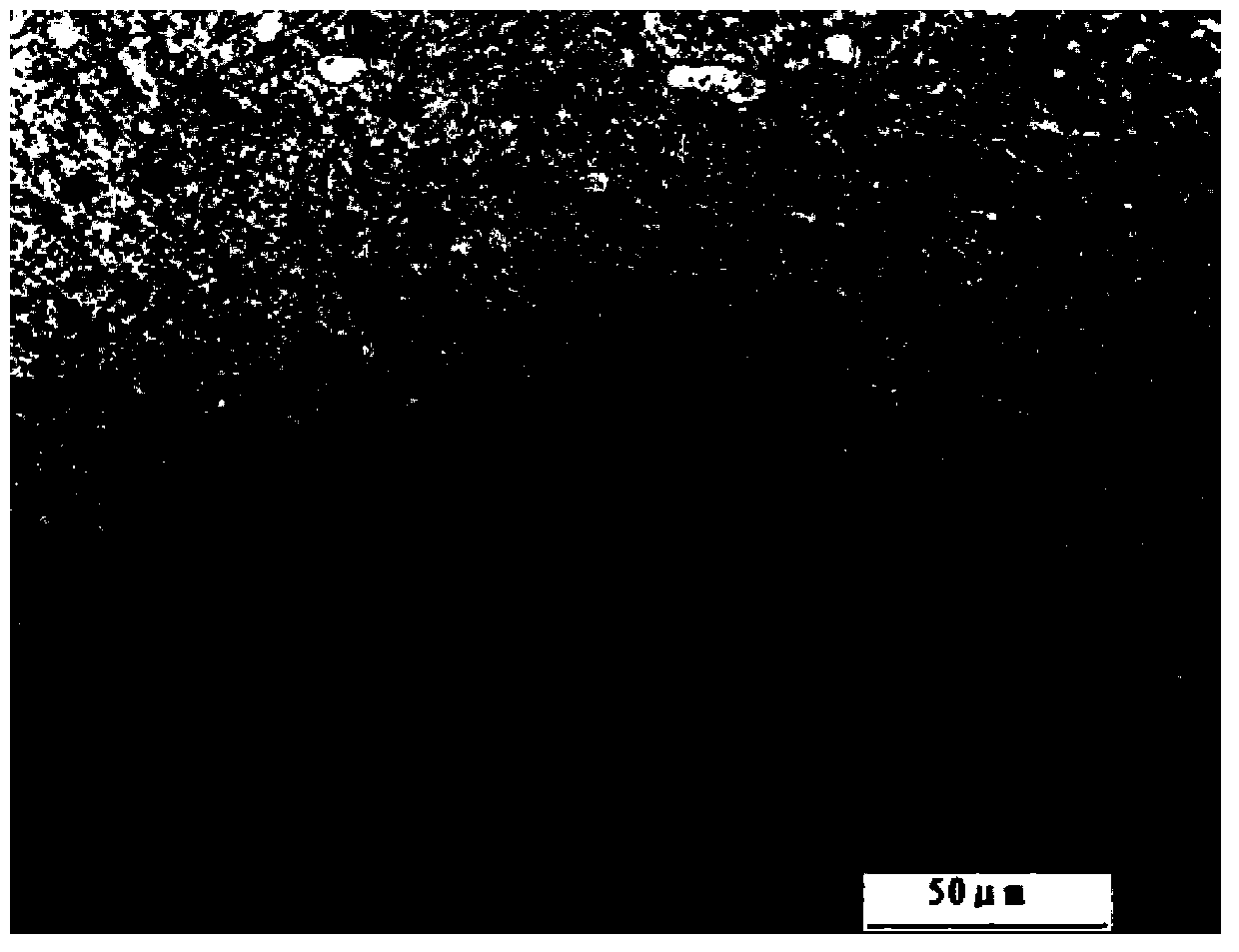

[0028]This embodiment is a method for obtaining a three-state structure in a titanium alloy. The sample used is a TA15 titanium alloy. The shape of the sample is cylindrical, and the specification of the sample is Φ55*70mm; the TA15 titanium alloy is Ti -6Al-2Zr-1Mo-1V. The β transformation point of TA15 titanium alloy is 990°C, and the initial structure is equiaxed.

[0029] The specific implementation steps of this embodiment are:

[0030] Step 1, heat treatment near β temperature. The resistance furnace is heated to the near β temperature of the TA15 titanium alloy, that is, the temperature range is 10-20°C lower than the β transformation point. In this embodiment, the temperature of the resistance furnace is 970°C, which is 20°C lower than the β temperature of the TA15 titanium alloy. When the temperature of the resistance furnace reaches 970°C, put the cylindrical sample into the resistance furnace. Heat the resistance furnace to 970°C and start heat preservation. The ...

Embodiment 3

[0034] This embodiment is a method for obtaining a three-state structure in a titanium alloy. The sample used is a TC4 titanium alloy. The shape of the sample is cylindrical, and the specification of the sample is Φ30*45mm; the TC4 titanium alloy is Ti -6Al-4V. The β transformation point of TC4 titanium alloy is 985°C, and the initial structure is equiaxed.

[0035] The specific implementation steps of this embodiment are:

[0036] Step 1, heat treatment near β temperature. The resistance furnace is heated to the near β temperature of the TC4 titanium alloy, that is, the temperature range is 10-20°C lower than the β transformation point. In this embodiment, the temperature of the resistance furnace is 975°C, which is 10°C lower than the β temperature of the TC4 titanium alloy. When the temperature of the resistance furnace reaches 975°C, put the cylindrical sample into the resistance furnace. Heat the resistance furnace to 975°C and start heat preservation. The heat preserv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com