Method for acquiring tri-modal microstructure in near-alpha titanium alloy

A titanium alloy and microstructure technology, which is applied in the field of three-state microstructure obtained by heat treatment of near-alpha titanium alloy, can solve the problems of high local temperature of forgings, complex forging control, restrictions, etc., and achieve easy temperature control, wide application range and uniform composition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

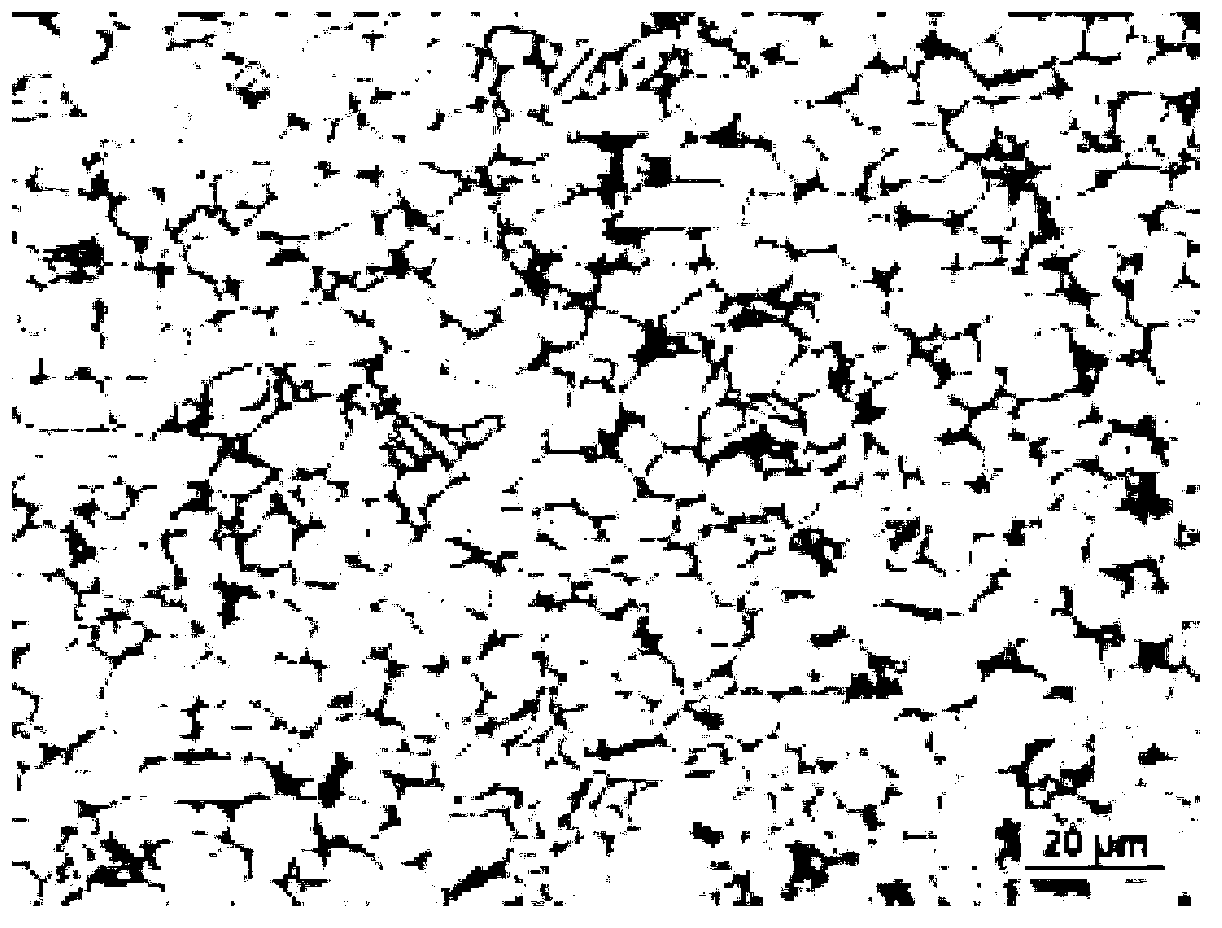

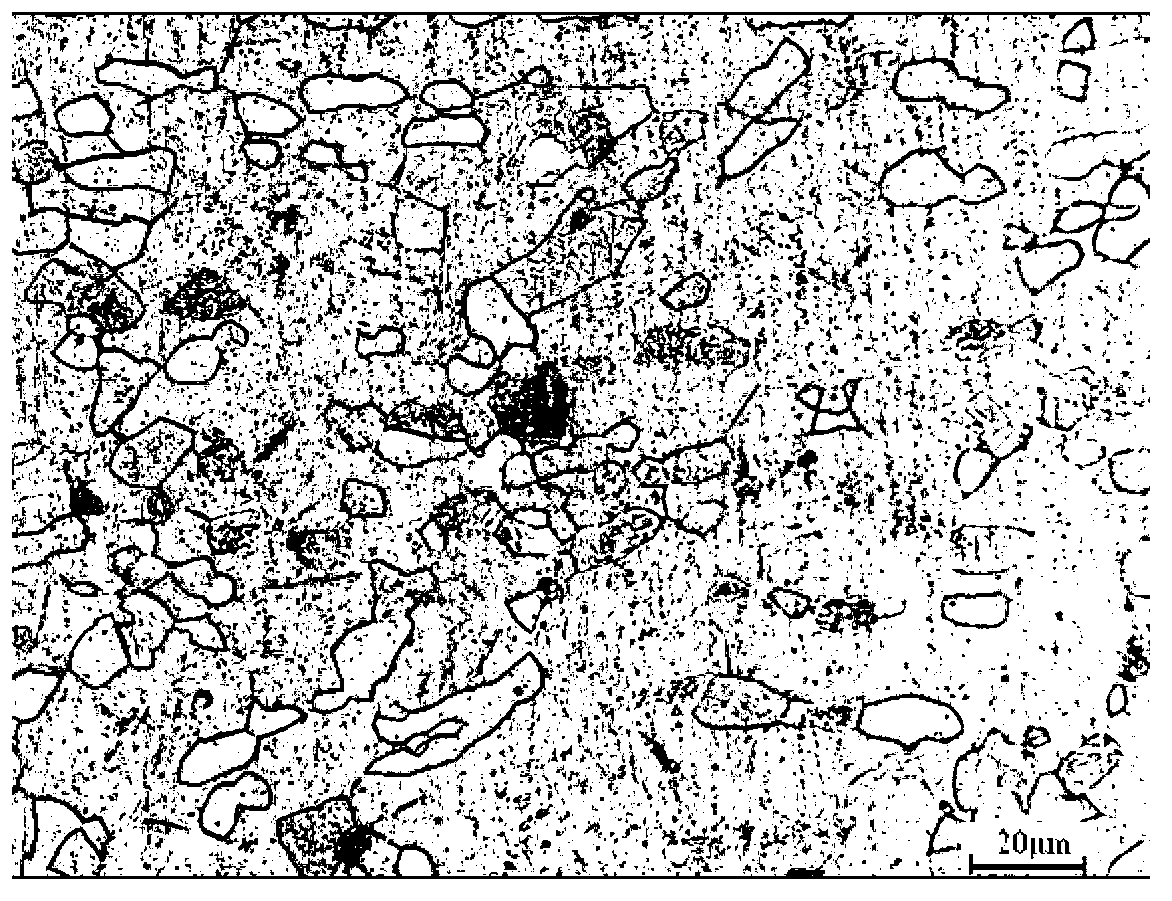

[0016] This embodiment is a method for obtaining a three-state structure in a near-α titanium alloy. The sample used is a TA15 titanium alloy, and the shape of the sample is cylindrical. The specification of the sample is Φ10*15mm; the TA15 titanium alloy It is Ti-6Al-2Zr-1Mo-1V. The β transformation point of TA15 titanium alloy is 990°C, and the initial structure is equiaxed.

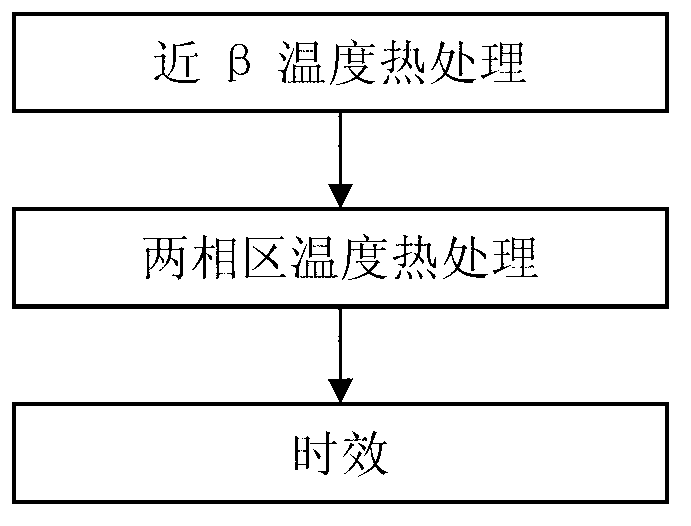

[0017] The specific implementation steps of this embodiment are:

[0018] Step 1, heat treatment near β temperature. The resistance furnace is heated to the near β temperature of the TA15 titanium alloy, that is, the temperature range is 10-20°C lower than the β transformation point. In this embodiment, the temperature of the resistance furnace is 975°C, which is 15°C lower than the β temperature of the TA15 titanium alloy. When the temperature of the resistance furnace reaches 975°C, put the cylindrical sample into the resistance furnace. Heat the resistance furnace to 975°C and start heat preserva...

Embodiment 2

[0025]This embodiment is a method for obtaining a three-state structure in a near-α titanium alloy. The sample used is a TA15 titanium alloy. The shape of the sample is cylindrical, and the specification of the sample is Φ210*300mm; the TA15 titanium alloy It is Ti-6Al-2Zr-1Mo-1V. The β transformation point of TA15 titanium alloy is 990°C, and the initial structure is equiaxed.

[0026] The specific implementation steps of this embodiment are:

[0027] Step 1, heat treatment near β temperature. The resistance furnace is heated to the near β temperature of the TA15 titanium alloy, that is, the temperature range is 10-20°C lower than the β transformation point. In this embodiment, the temperature of the resistance furnace is 970°C, which is 20°C lower than the β temperature of the TA15 titanium alloy. When the temperature of the resistance furnace reaches 970°C, put the cylindrical sample into the resistance furnace. Heat the resistance furnace to 970°C and start heat preserv...

Embodiment 3

[0032] This embodiment is a method for obtaining a three-state structure in a titanium alloy. The sample used is a TA11 titanium alloy. The shape of the sample is cylindrical, and the specification of the sample is Φ15*25mm; the TA11 titanium alloy is Ti -8Al-1Mo-1V. The β transformation point of TA11 titanium alloy is 1040 ℃, and the initial structure is equiaxed.

[0033] The specific implementation steps of this embodiment are:

[0034] Step 1, heat treatment near β temperature. The resistance furnace is heated to the near β temperature of the TA11 titanium alloy, that is, the temperature range is 10-20°C lower than the β transformation point. In this embodiment, the temperature of the resistance furnace is 1020°C, which is 20°C lower than the β temperature of the TC4 titanium alloy. When the temperature of the resistance furnace reaches 1020°C, put the cylindrical sample into the resistance furnace. Heat the resistance furnace to 1020°C and start heat preservation. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com