Solid heat storage structure and processing method

A processing method and solid technology, applied in solar heat storage, chemical instruments and methods, heat storage equipment, etc., can solve the problems of inability to form self-support, large heat loss in heat preservation cycle, affecting heat storage capacity, etc., and achieve a good overall exchange rate. Thermal performance, good interfacial heat transfer performance, and the effect of improving bonding and welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the examples.

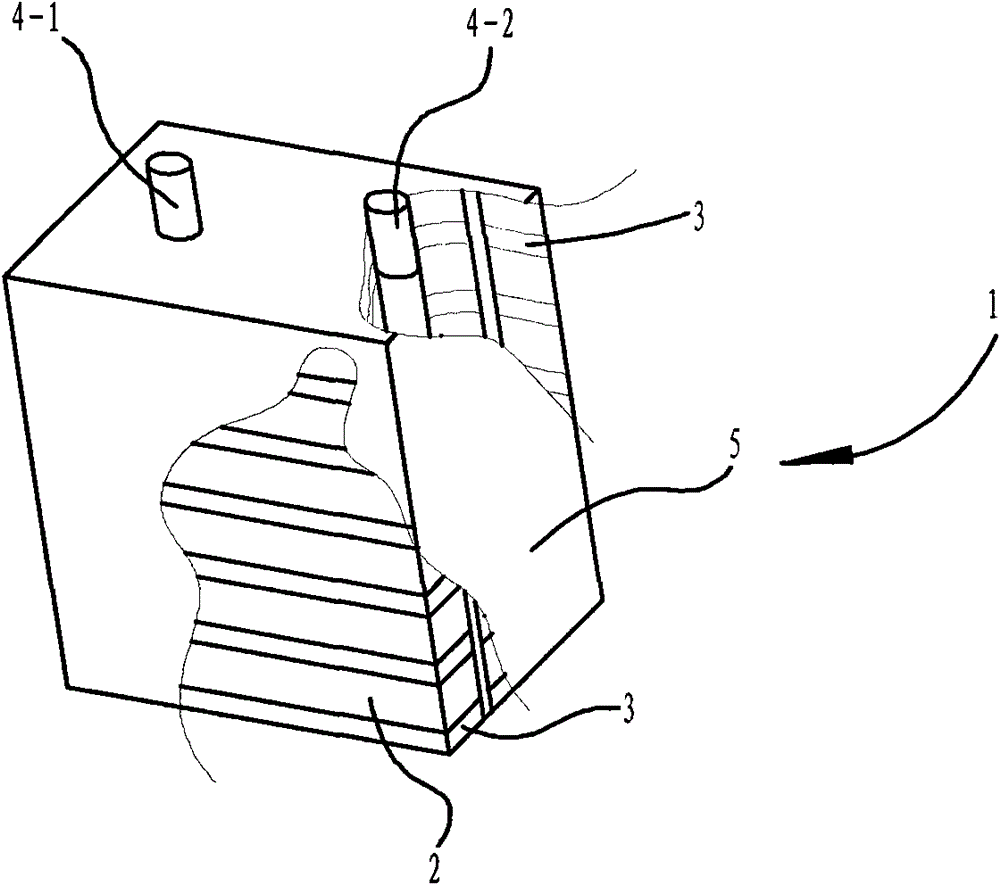

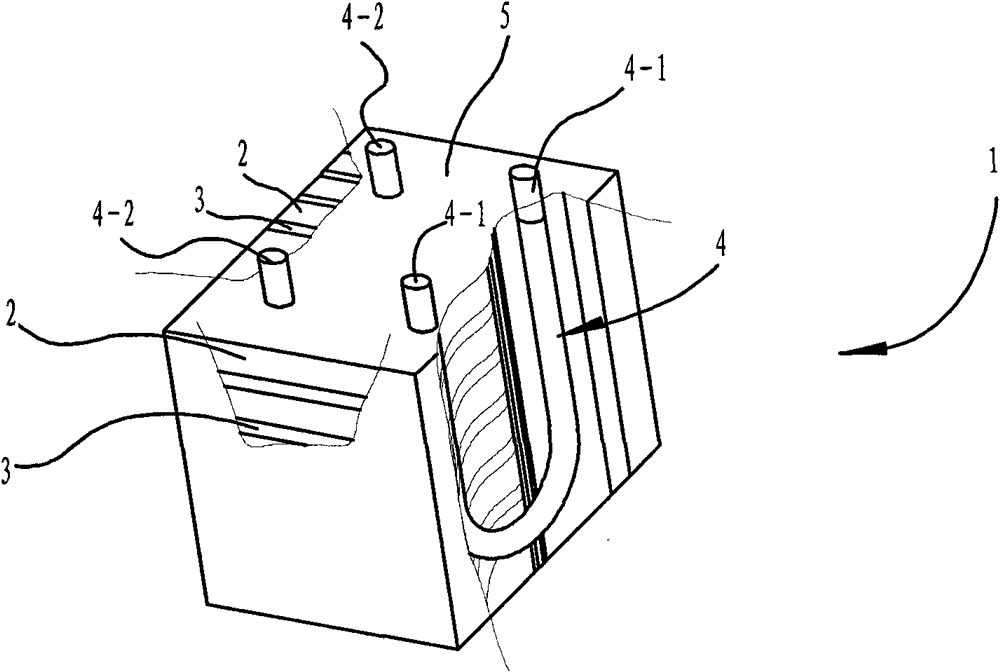

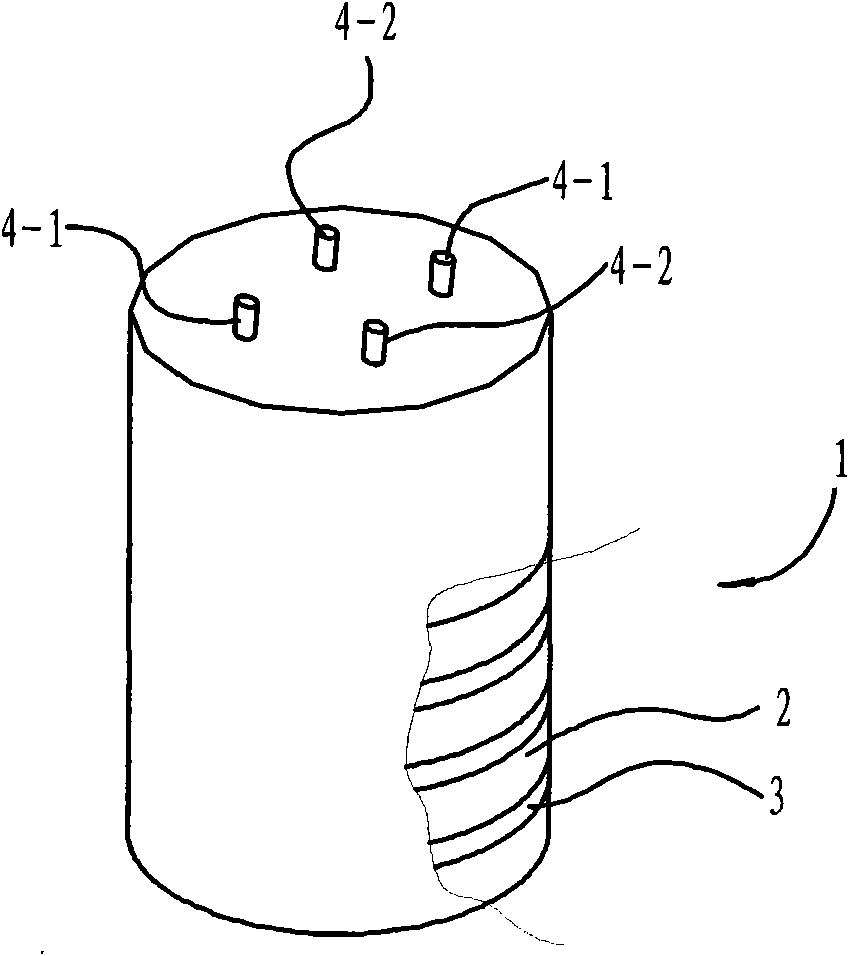

[0039] figure 1 , figure 2 and image 3 It is a schematic diagram of a structural embodiment of the overall structure of the solid heat storage structure 1 of the present invention at different application temperatures. As shown in the figure, the solid heat storage structure 1 is formed by stacking a plurality of regular-shaped solid heat storage blocks 2, preferably solid heat storage blocks 2 of one or more shapes or sizes, specifically including solid heat storage blocks 2 and A high thermal conductivity bonded filling material 3; a solid heat storage structure 1 with high thermal conductivity and heat storage formed integrally by the two. A heat exchange pipe 4 is arranged inside the solid heat storage structure 1, preferably a metal heat exchange pipe 4, and the high thermal conductivity adhesive filling material 3 is in close and good contact with the heat exch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com