A spray evaporation system for low-temperature heating of air source heat pumps and air conditioners

An air source heat pump and spray evaporation technology, which is used in the field of air source heat pump and low temperature heating of air conditioners, can solve the conditions and requirements that cannot meet the normal heating of the compressor, cannot evaporate enough refrigerant gas from the compressor, and increase the amount of refrigerant gas. Large system evaporation area and other problems, to achieve the effect of reducing the amount of evaporating refrigerant, reducing the cost of evaporation, and reducing the cost of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

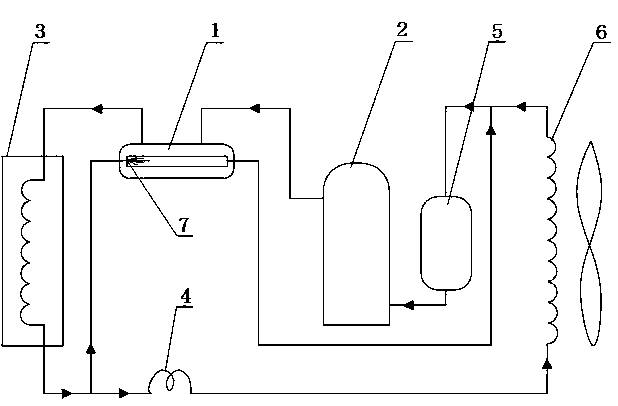

[0024] First, in the working state of the compressor 2 for low-temperature heating, the gas heated up by the compressor 2 enters the heat exchanger 3 through the exhaust pipe for heat exchange, and then becomes a gas-liquid mixed refrigerant medium.

[0025] At this time, the high-pressure and low-temperature gas-liquid mixed refrigerant medium in the system passes through the capillary 4. Here, it is divided through a three-way, and a part passes through the spray evaporator 1. Under the high pressure of the system, the pressure nozzle 7 in the spray evaporator 1 will The gas-liquid mixed refrigerant is sprayed out to form misty refrigerant droplets; because the high-temperature gas generated by the compressor 2 enters the interlayer of the spray evaporator 1 through the exhaust pipe, the atomized refrigerant droplets are instantly passed through the heat-absorbing gas After melting, it directly enters the liquid storage tank 5, and then enters the compressor 2.

[0026] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com