Integrated synergistic recovery method for sodium sulfate and methanol in pirimiphos-methyl production wastewater

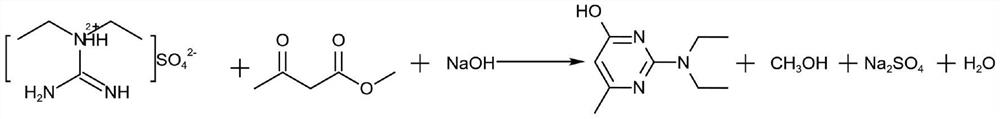

A technology for producing pirimiphos-methyl and waste water, which is applied in chemical instruments and methods, separation/purification of hydroxyl compounds, alkali metal sulfite/sulfite, etc., which can solve waste of water resources, sulfate by-products, and environmental impact Large scale, waste water generation and other problems, to achieve the effect of improving salt efficiency, improving the environment and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

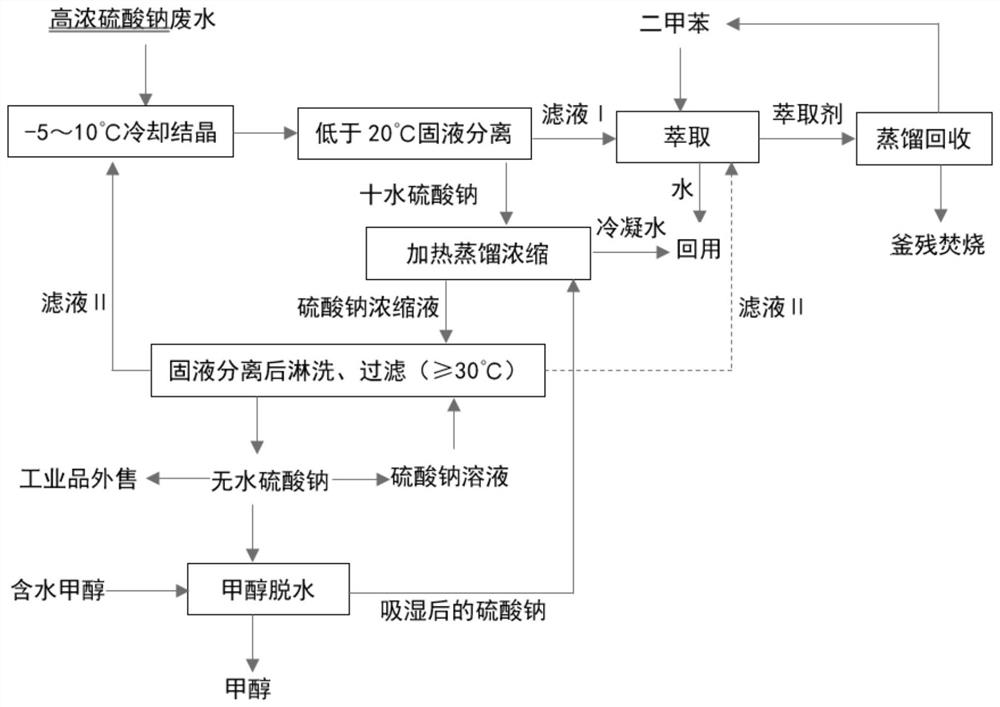

[0045] An integrated synergistic recovery method of sodium sulfate and methanol in pirimiphos-methyl production wastewater, such as figure 1 shown, including the following steps:

[0046] Get 2 liters of high-concentration sodium sulfate waste water produced by the pyrimidinol production workshop. After analysis, the sodium sulfate content in the waste water is 25%; get 1 kg of hydrous methanol collected in the pyrimidinol production process, and the analyzed moisture content is 2%. The process of recovering sodium sulfate from the wastewater and realizing wastewater reuse and methanol dehydration is as follows:

[0047] (1) Under stirring conditions, the high-concentration sodium sulfate wastewater was cooled to 2°C, crystallized for 60min, and filtered at a temperature of 20°C to obtain 1593g of wet solids (sodium sulfate decahydrate) and 829g of filtrate (filtrate I ).

[0048] (2) with 42g (5% of filtrate quality) the filtrate (filtrate I) that obtains in xylene extracti...

Embodiment 2

[0054] An integrated synergistic recovery method of sodium sulfate and methanol in pirimiphos-methyl production wastewater, such as figure 1 shown, including the following steps:

[0055] Get the high-concentration sodium sulfate waste water that 2 liters of pyrimidinol production workshops produce, sodium sulfate content is 15% through analysis waste water, and mix with the 457g filtrate II that obtains in embodiment 1 step (4); Get 1kg pyrimidinol production process The collected aqueous methanol was analyzed to have a moisture content of 1.8%.

[0056] (1) High-concentration sodium sulfate wastewater (containing the 457g filtrate II obtained in step (4) of Example 1) was stirred and cooled to -5°C, crystallized for 30min, and filtered at a temperature of 15°C to obtain 1275g of wet solids (sodium sulfate decahydrate) and 1275 g of the filtrate (filtrate I).

[0057] (2) with 102g (8% of filtrate quality) the filtrate (filtrate I) that obtains in xylene extraction step (1)...

Embodiment 3

[0063] An integrated synergistic recovery method of sodium sulfate and methanol in pirimiphos-methyl production wastewater, such as figure 1 shown, including the following steps:

[0064] Get 2 liters of high-concentration sodium sulfate wastewater produced by the pyrimidinol production workshop, and the sodium sulfate content in the waste water is analyzed to be 24%; get 1 kg of hydrous methanol collected in the pyrimidinol production process, and the analyzed moisture content is 2.1%.

[0065] (1) High-concentration sodium sulfate wastewater was stirred and cooled to 10°C, crystallized for 120 minutes, and filtered at a temperature of 10°C to obtain 1588g of wet solid (sodium sulfate decahydrate) and 878g of filtrate (filtrate I).

[0066] (2) Heat the wet solid (sodium sulfate decahydrate) obtained in step (1) to 100°C, carry out distillation and concentration, stop heating when steaming 715g of water, and the gained concentrate is naturally cooled to 36°C at room temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com