Segmented mining method

A mining method and ore block technology, which is applied in special mining, earth square drilling, open-pit mining, etc., can solve problems such as low air pressure, low oxygen content in the air, and reduced efficiency of personnel and equipment, so as to achieve high-efficiency mining and mining. The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

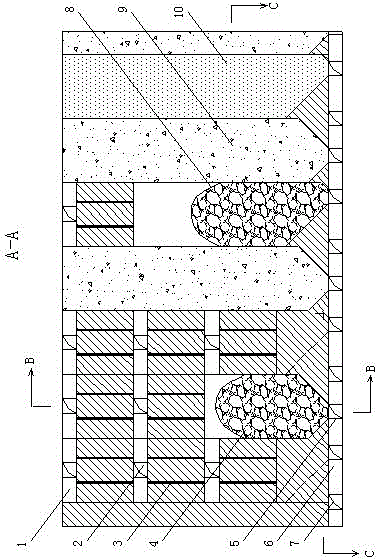

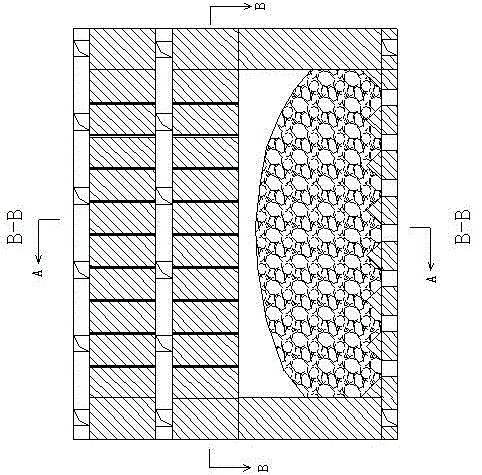

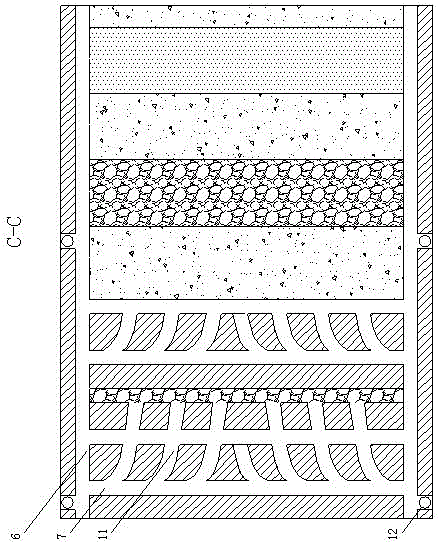

[0069] A very large copper polymetallic mine with an altitude of 4500m. The ore body occurs in skarn, the roof is hornfels, slates and dikes, and the floor is carbonate rock. The integrity of the rock is good, and the joints and fissures are not developed. The ore body is in the shape of a thick plate, with a thickness of 25-60m, and some are extremely thick and large ore bodies. The dip angle of the ore body changes greatly. The upper part with a dip angle greater than 50° is a steeply inclined ore body, and the lower part is a nearly horizontal and gently inclined ore body. The mining area is dominated by gently inclined ore bodies. The altitude of the mining area is high, the air is thin, and the mining operation environment is poor. Subsidence and large deformation are not allowed on the ground surface. It is mined by the method of cluster hole high-section open-field and then-fill mining, with a stage height of 60m and a section height of 20m. The ore block is 100m lo...

Embodiment 2

[0072] A copper polymetallic mine with an altitude of 3900m. The ore deposit is a volcanic exhalation deposit, and the ore-bearing belt is mainly a set of rhyolitic pyroclastic rocks. The main ore body runs north-south and dips east. Dip 80 0 about. The strike length is 200-960m. The average thickness is 22.5m. The ore body is lens-shaped. The ore body and surrounding rock are stable. The altitude of the mining area is high, the air is thin, and the mining operation environment is poor. Subsidence and large deformation are not allowed on the ground surface. The mine is mined by the method of cluster hole high-section open-field and then-fill mining, with a stage height of 50m and a section height of 15m. The ore block is 80m long and 30m wide, the mine room in the ore block is 60m long, the mine room is 15m wide, the column width is 15m, and the panel column width is 20m. During mining, the mining room and the empty area of the mining room are cemented and filled fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com