Method for fixing object and expansion bolt and special borer for method

A technology for expansion bolts and objects, which is applied in drilling equipment and methods, connecting components, earth-moving drilling, etc., can solve problems such as safety accidents, objects falling off, and expansion bolts are not recommended, so as to avoid accidents, prevent objects from falling, The effect of improving the anti-shedding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

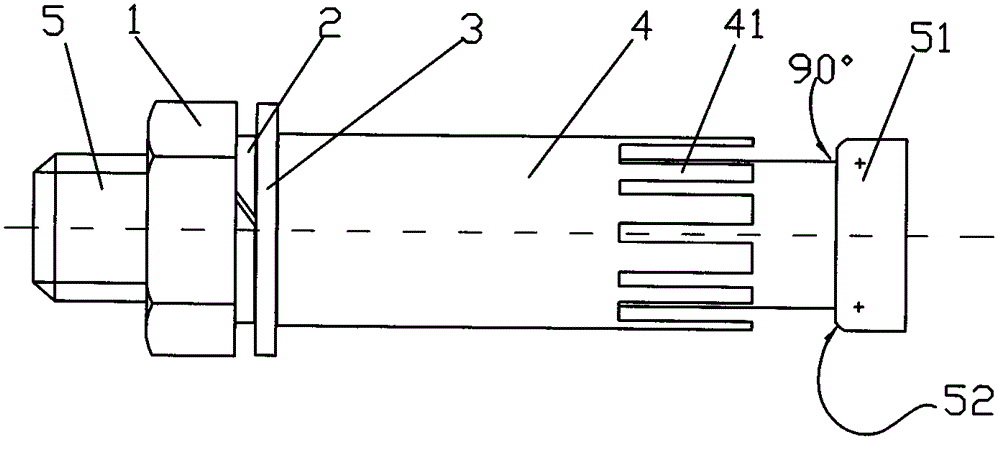

[0036] The expansion bolt of the present invention consists of a nut 1, a spring washer 2, a flat washer 3, an expansion sleeve 4, and a screw 5. The diameter of the screw tail 51 is greater than the diameter of the screw shaft and is substantially equal to the outer diameter of the expansion sleeve 4. The expansion sleeve 4 is made of round steel pipe, the thickness of the pipe wall is greater than that of the traditional iron expansion sleeve, and its tail is cut into 10 petals 41 by a sawing machine. The junction of the screw tail 51 and the screw shaft is at right angles, and the screw tail is at The side facing the expansion sleeve is made into an arc chamfer 52, such as image 3 shown. When the nut 1 is tightened, the arc surface chamfer 52 at the tail of the screw first expands the petals, and then exerts an axial extrusion force on the petals, forcing the petals to bend at a right angle. When the screw retreats a sufficient distance, each petal Bending outwards to for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com