Solidifying device and process for composite non-woven fabrics

A non-woven fabric and equipment technology, which is applied in the field of composite non-woven fabric consolidation equipment and technology, can solve the problems of non-woven fabric performance degradation, sticking into sheets or strips, affecting the softness and water absorption of non-woven fabrics, etc. Achieve the effect of avoiding sticking into sheets or strips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

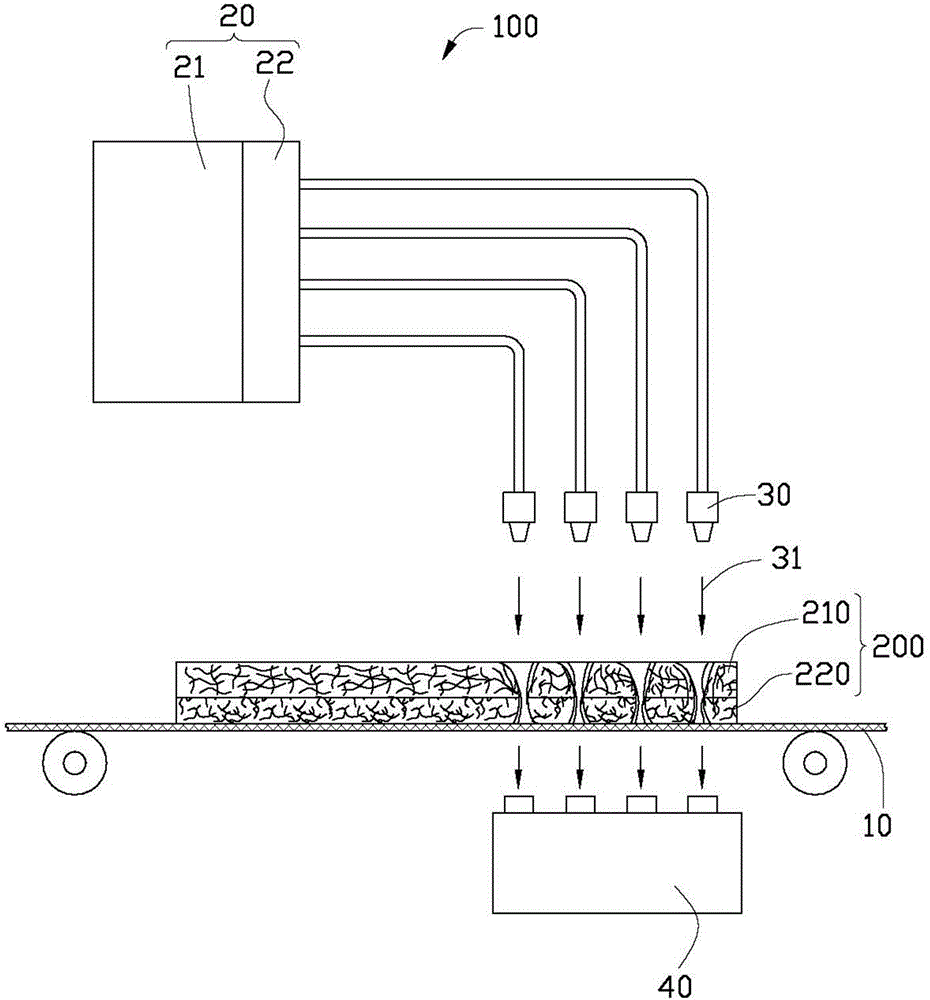

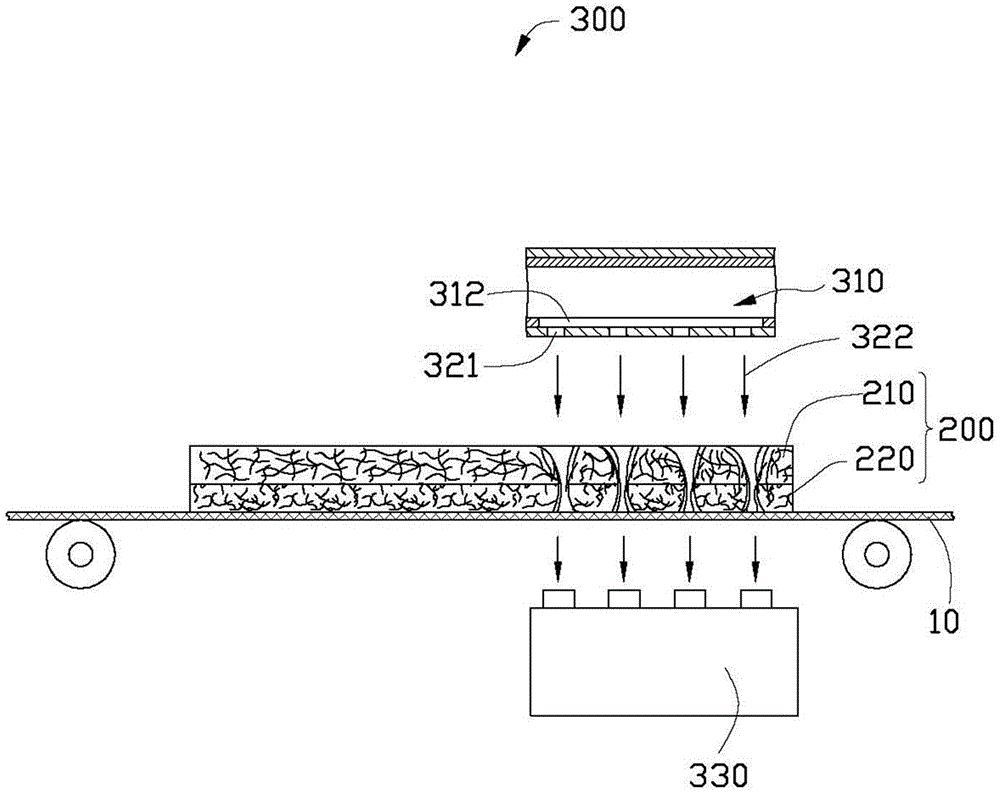

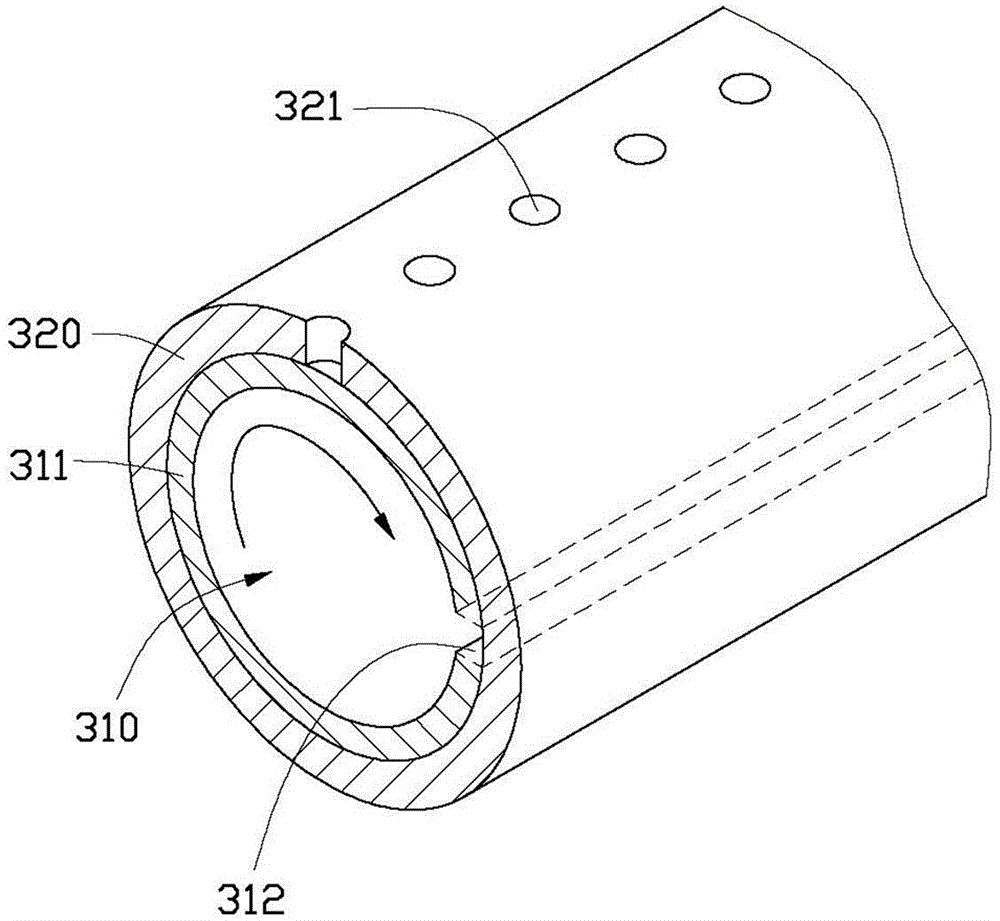

[0016] See figure 1 As shown, the composite non-woven fabric consolidation equipment 100 provided by the first embodiment of the present invention is used to consolidate the non-woven fabric fiber composite body 200, and the non-woven fabric fiber composite body 200 includes the first hot-melt fiber layer 210 and a hydrophilic fiber layer 220 stacked under the first heat-melt fiber layer 210 . The composite non-woven fabric consolidation device 100 includes a supporting mesh curtain 10 , a hot air source 20 , a plurality of injection ports 30 and a vacuum device 40 .

[0017] The supporting net curtain 10 is used to support the non-woven fiber composite 200 and transport it at a certain speed, so as to facilitate the consolidation of the non-woven fiber composite 200 by the composite non-woven consolidation device 100 Knot handling.

[0018] It can be understood that, in the present invention, the supporting mesh curtain 10 may be a part of the nonwoven fabric manufacturing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com