Injection molding material, preparation method thereof, and injection molding product thereby

A manufacturing method and injection molding technology, applied in injection molding products, injection molding materials and their manufacturing fields, can solve the problems of low production stability and pass rate, no metal glitter powder texture on the surface, single color of injection molding products, etc., and achieve high pass rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0016] The "injection plastic rice" mentioned in the present invention is a solid particle for injection molding made of thermoplastic or thermosetting material.

[0017] The "metal glitter powder" mentioned in the present invention refers to a brilliant and high-gloss metallic effect pigment made of metal-wrapped glass flakes or natural mica.

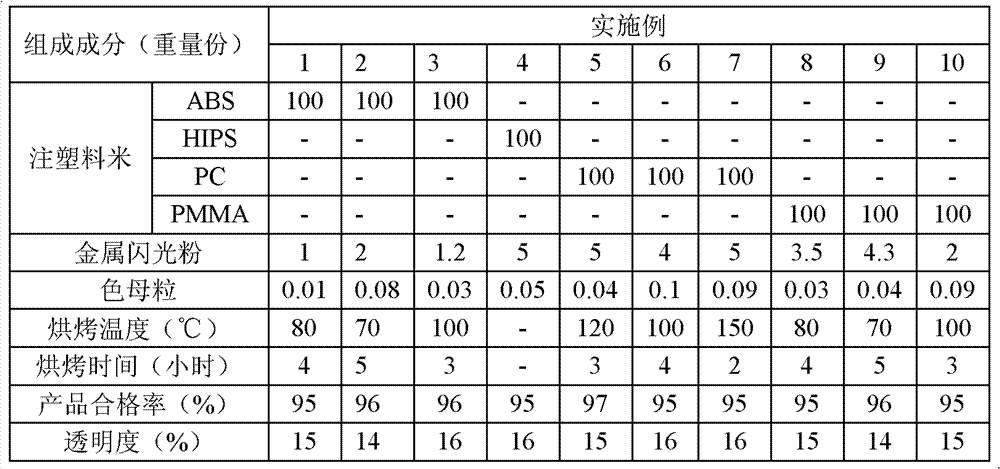

[0018] The injection molding material provided by the invention comprises injection plastic rice and metal glitter powder, wherein the weight ratio of metal glitter powder to injection plastic rice is 1-5:100. It can be understood that those skilled in the art can also add other additives that can improve the performance of the injection molding material, such as brighteners, lubricants, etc., to the injection molding material according to actual needs. When the amo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com