Arsenic-removing material of nano ferrimanganic composite oxide and preparation method thereof

A composite oxide and nano-iron-manganese technology, which is applied in the field of water treatment, can solve the problems of easy oxidation of ferrous salt, uneasy control of operating conditions, and low yield of products, achieving excellent removal effect, simple and controllable preparation process, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

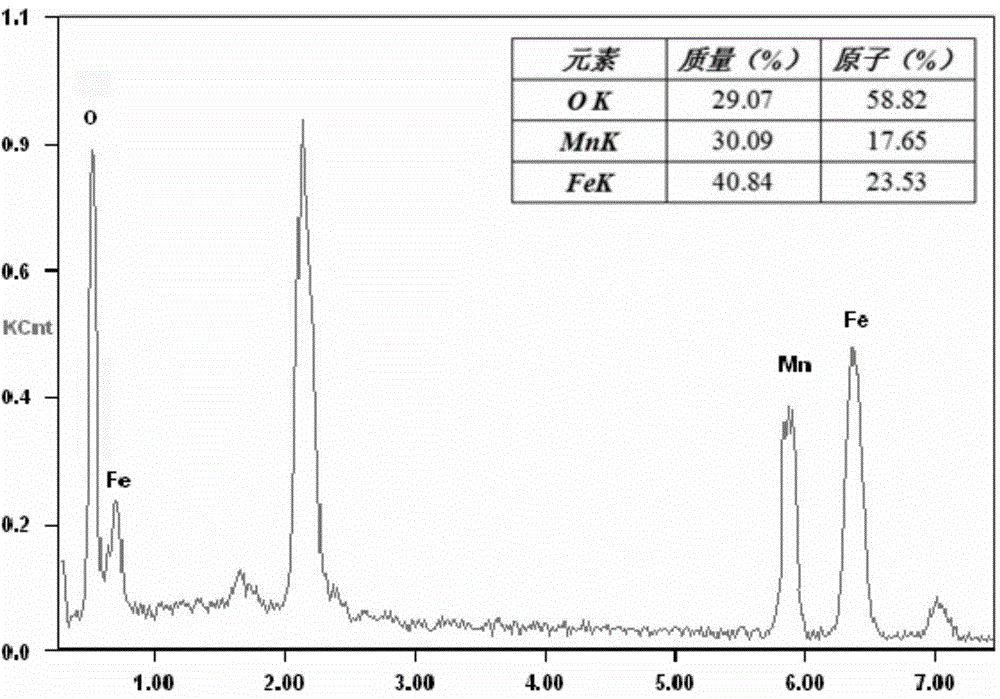

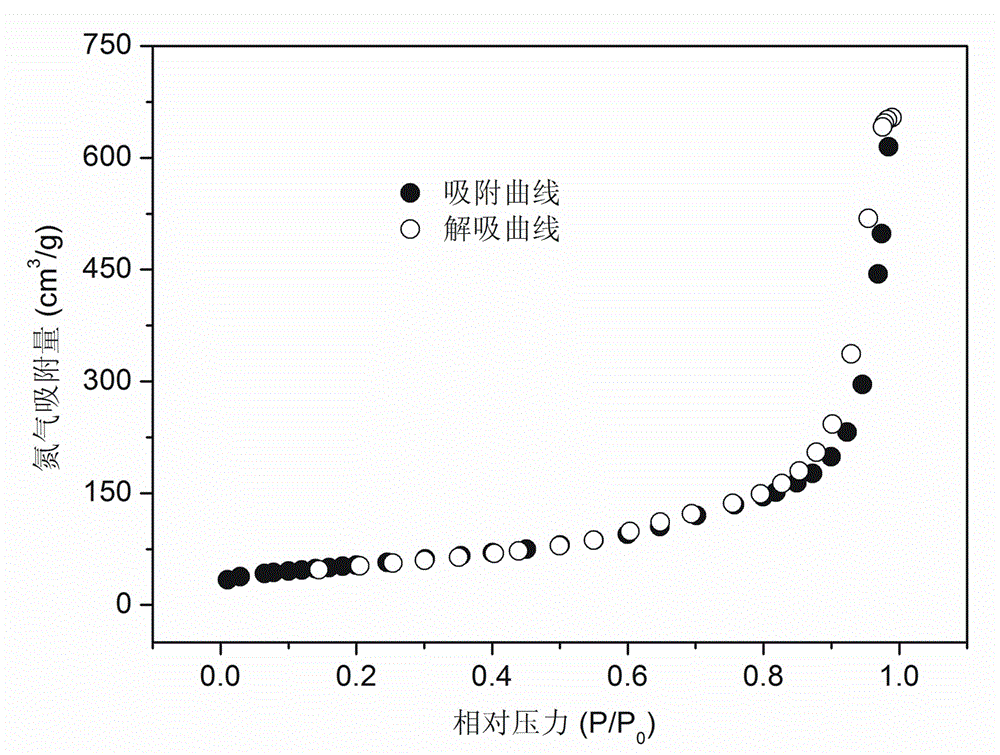

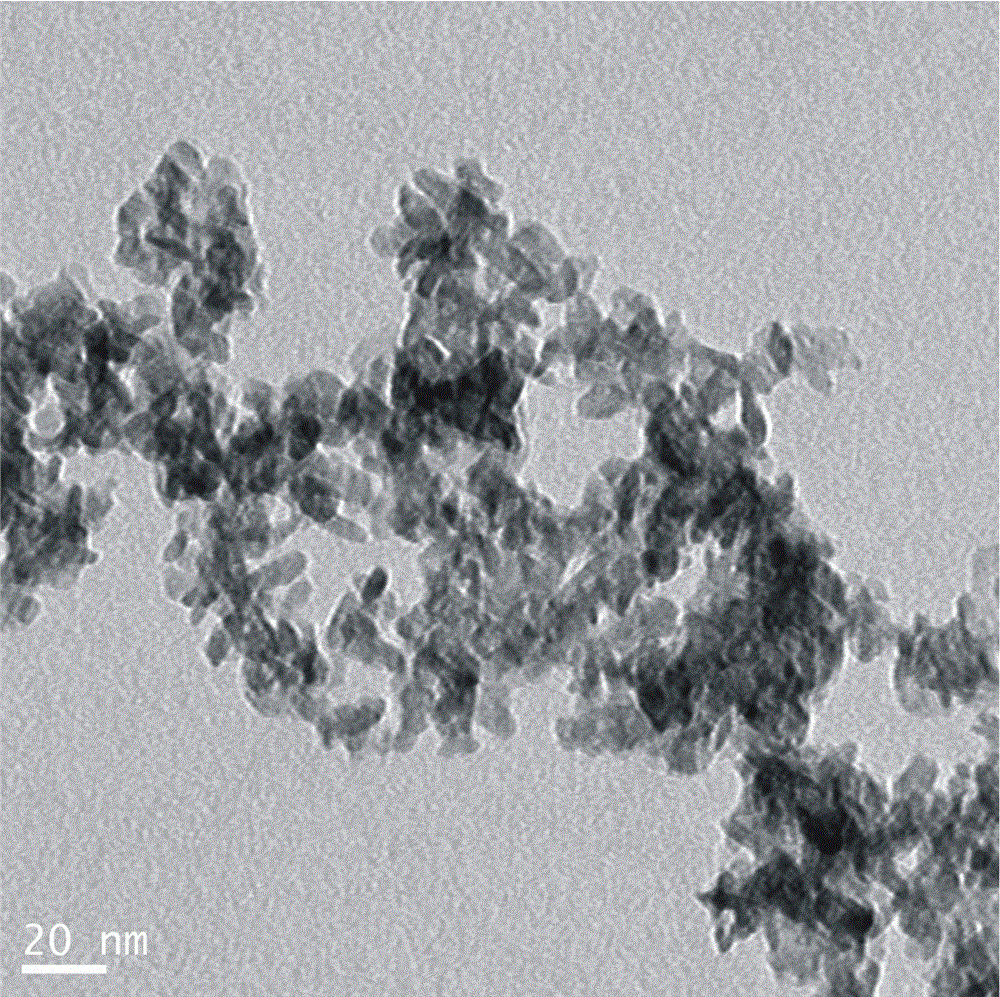

[0030] An arsenic-removing material for nano-iron-manganese composite oxide, which is a nano-iron-manganese composite oxide containing iron, manganese and oxygen in an atomic ratio of 4:3:10, wherein manganese is +4, and iron is +3 valence, the BET specific surface area of the arsenic removal material is 282 m 2 / g, the average particle size is 20 nm.

[0031] The arsenic-removing material of the above-mentioned nano-iron-manganese composite oxide, its preparation method comprises the following steps:

[0032] (1) Weigh 9.48 grams of KMnO 4 and 21.62 g FeCl 3 ·6H 2 O was respectively dissolved in 500ml deionized water, the above-mentioned ferric chloride solution was atomized into droplets and sprayed into the KMnO4 solution, and the pH value of the system was adjusted to 8 by using 1 mol / L sodium hydroxide to keep it stable;

[0033] (2) to be FeCl 3 ·6H 2 After the O solution is sprayed in, heat the above solution to 90°C on an electric furnace, and continue heating ...

Embodiment 2

[0041] A material for removing arsenic from nano-iron-manganese composite oxides, which is a nano-iron-manganese composite oxide containing iron, manganese and oxygen in an atomic ratio of 4:3:8, wherein manganese is +4, and iron is +3 valence, the BET specific surface area of the arsenic removal material is 225 m 2 / g, with an average particle size of 10 nm.

[0042] The arsenic-removing material of the above-mentioned nano-iron-manganese composite oxide, its preparation method comprises the following steps:

[0043] (1) Weigh 11.76 grams of NaMnO 4 ·3H 2 O and 21.62 g FeCl 3 ·6H 2 O was dissolved in 500ml deionized water respectively, and the ferric chloride solution was atomized into droplets and sprayed into NaMnO 4 In the solution, the potassium hydroxide of 3mol / L is used to regulate the pH value of the system to be 10 and keep it stable;

[0044] (2) to be FeCl 3 ·6H 2 After the O solution is sprayed in, heat the above solution to 95°C on an electric furnace, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com