Method and device for obtaining a multicrystalline semiconductor material, in particular silicon

A semiconductor and equipment technology, applied in the direction of polycrystalline material growth, lighting and heating equipment, crystal growth, etc., can solve problems such as increasing energy consumption levels, increasing costs, and the overall size of furnaces, high energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

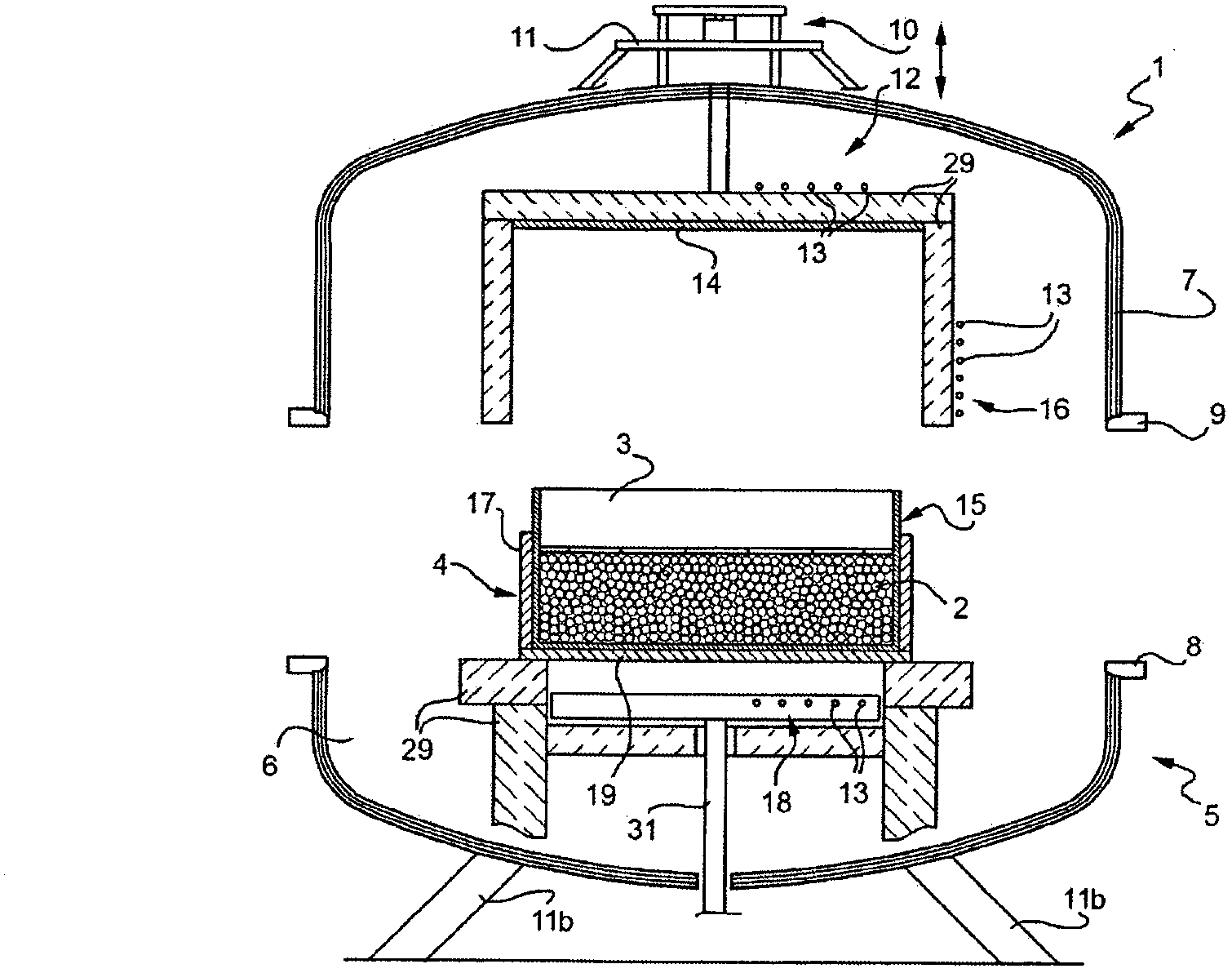

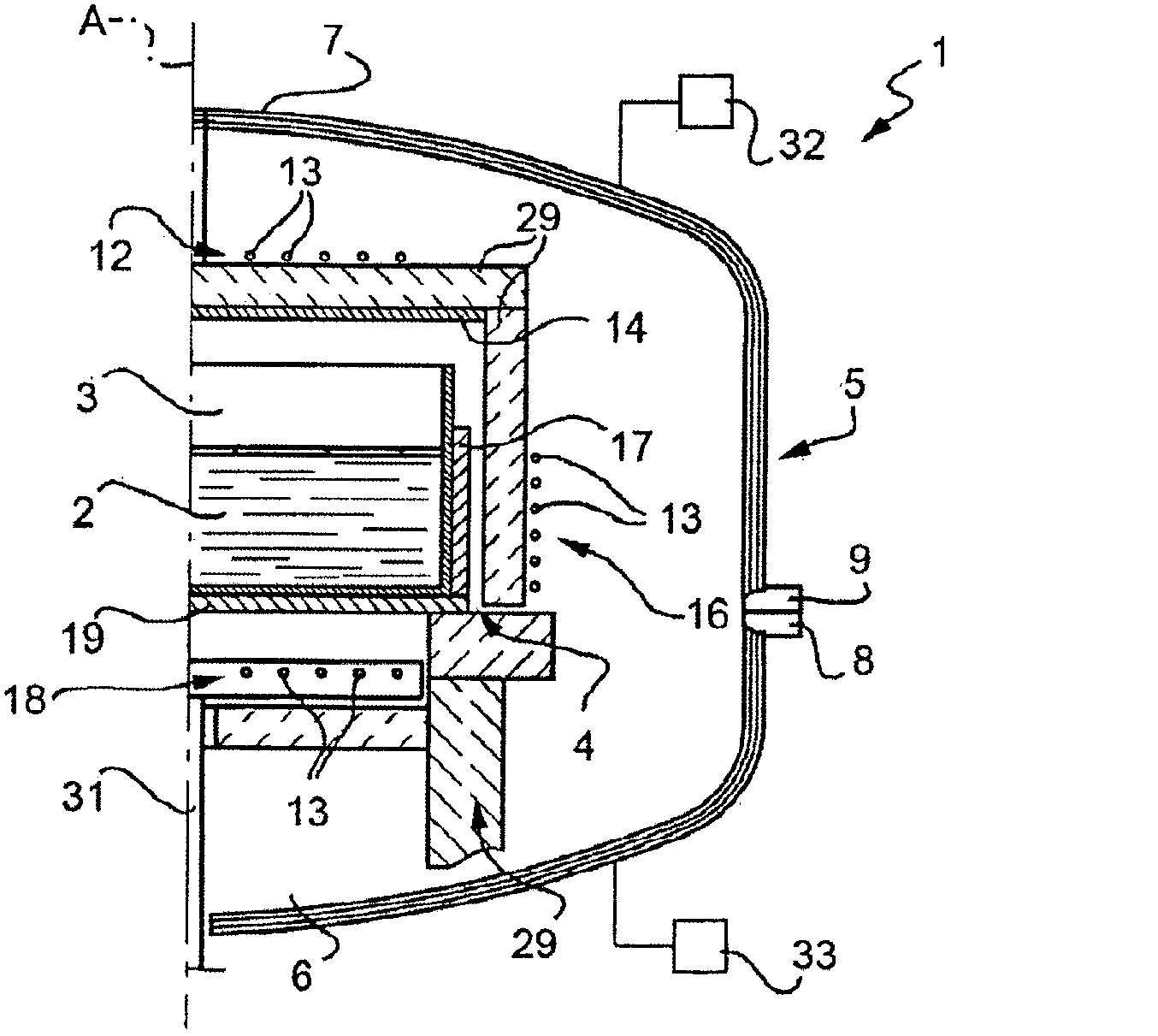

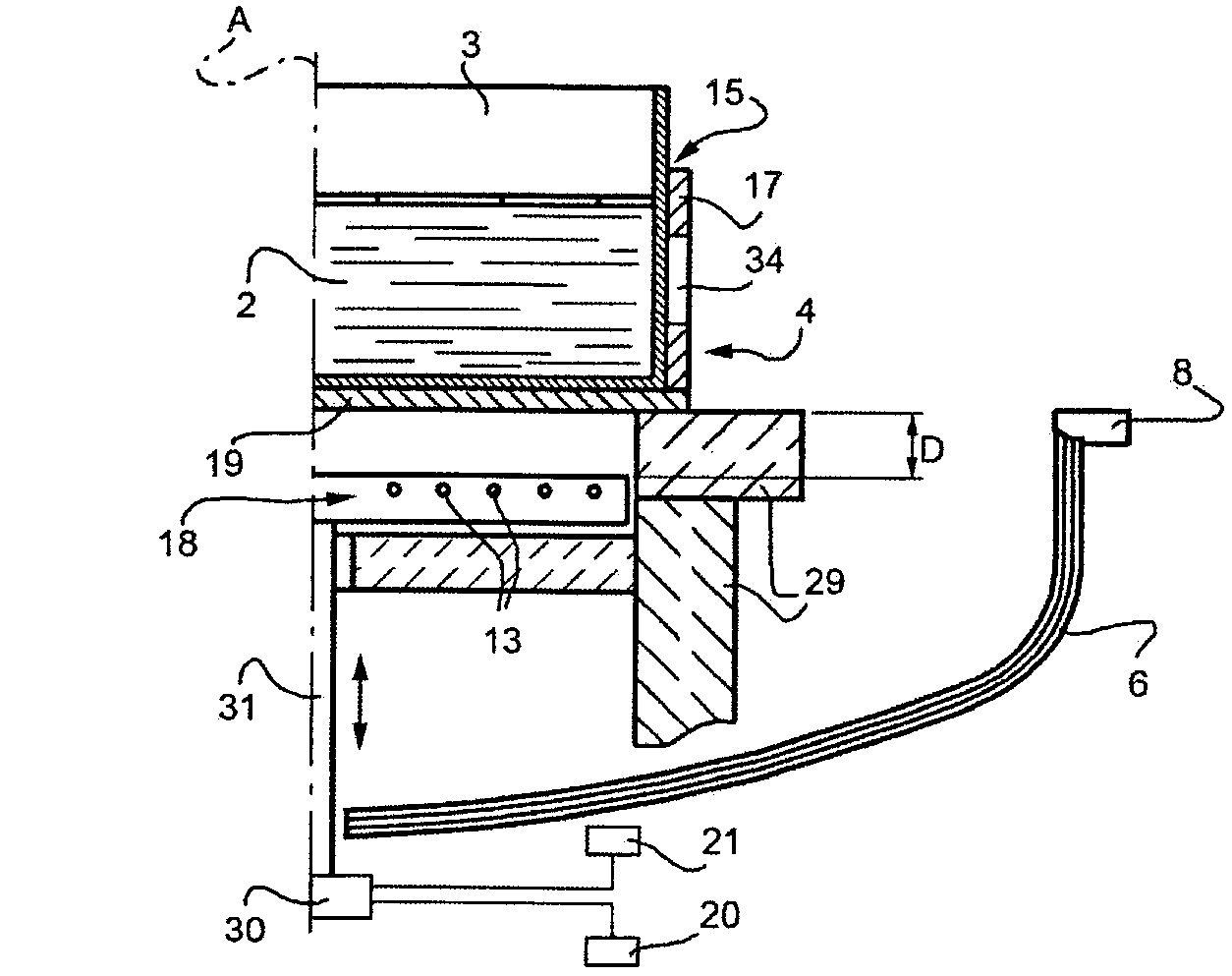

[0026] refer to Figure 1-Figure 4 , 1 collectively designates the equipment for the melting and subsequent directional solidification of semiconductor material 2, typically obtaining polysilicon of solar purity grade.

[0027] The apparatus 1 comprises: at least one crucible 3 for semiconductor material 2, preferably made of quartz or ceramic material, removably arranged in a cup-shaped graphite container 4; and a fluid-tight enclosure 5, in which the graphite container 4 is arranged , the fluid-tight casing 5 is bounded by a lower half-shell 6 and an upper half-shell 7, both cup-shaped; these shells are preferably made of steel and are usually connected up and down relative to each other ( figure 2 ), their concavities facing each other, the respective edges 8, 9 with appropriate gaskets (not shown) abut together in a fluid-tight manner.

[0028] The device 1 also comprises means 10 for vertically moving the upper half-shell 7 away from the lower half-shell 6, in this case...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com