Induction heating system with external combined induction heating coil phased arrays and application for induction heating system

An induction heating coil and induction heating technology, applied in the field of external combined induction heating coil and its timing control heating system, can solve the problems of mutual interference of magnetic fields, large thermal efficiency loss, etc., and achieve the effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

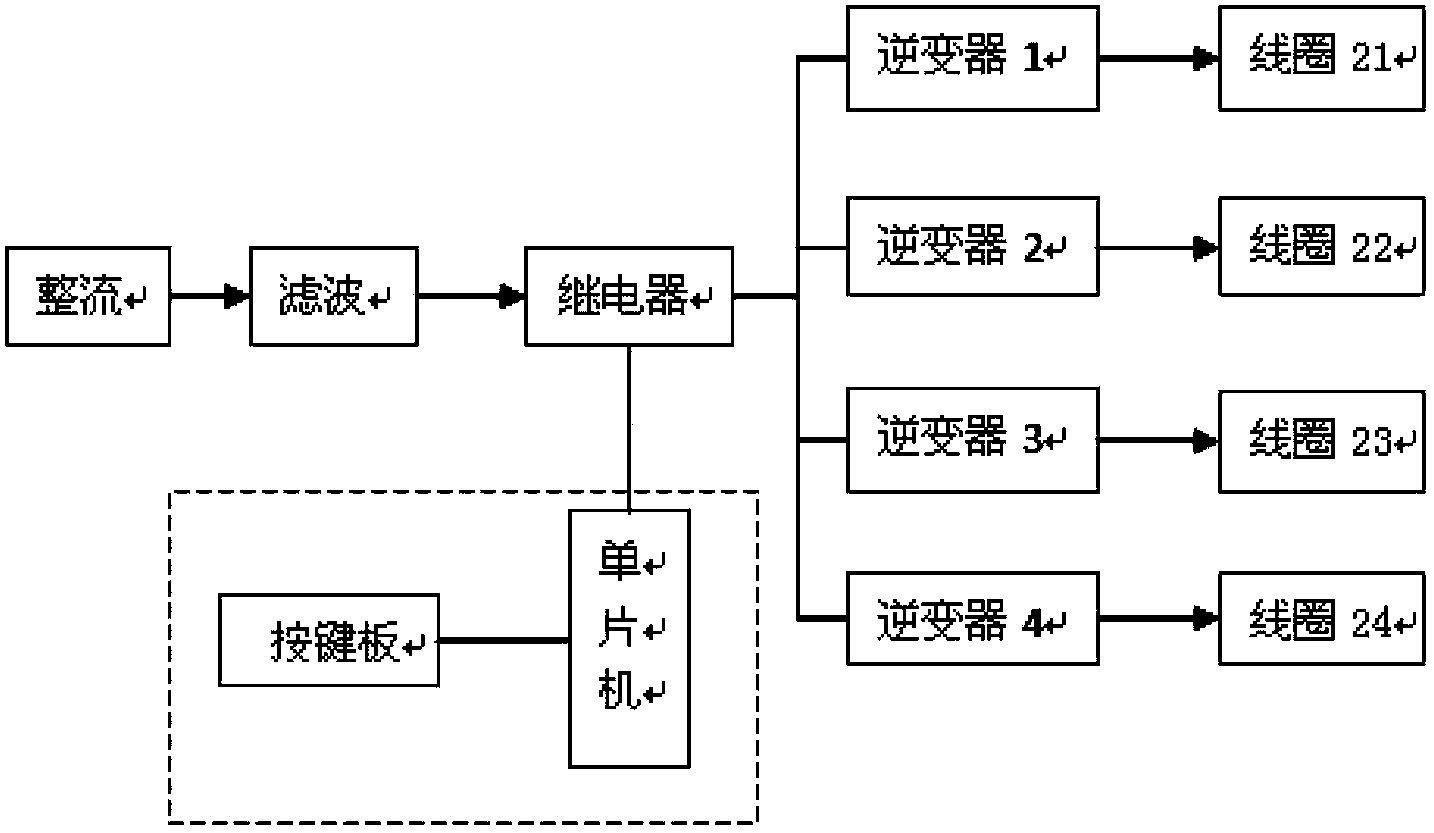

[0036] In a preferred embodiment of the present invention, as figure 1 As shown, taking a 2×2 combined induction heating coil as an example, the technical solution adopted in the present invention is mainly completed by an 8-bit single-chip microcomputer (C52), a keypad, a relay, an inverter, and a 2×2 combined coil.

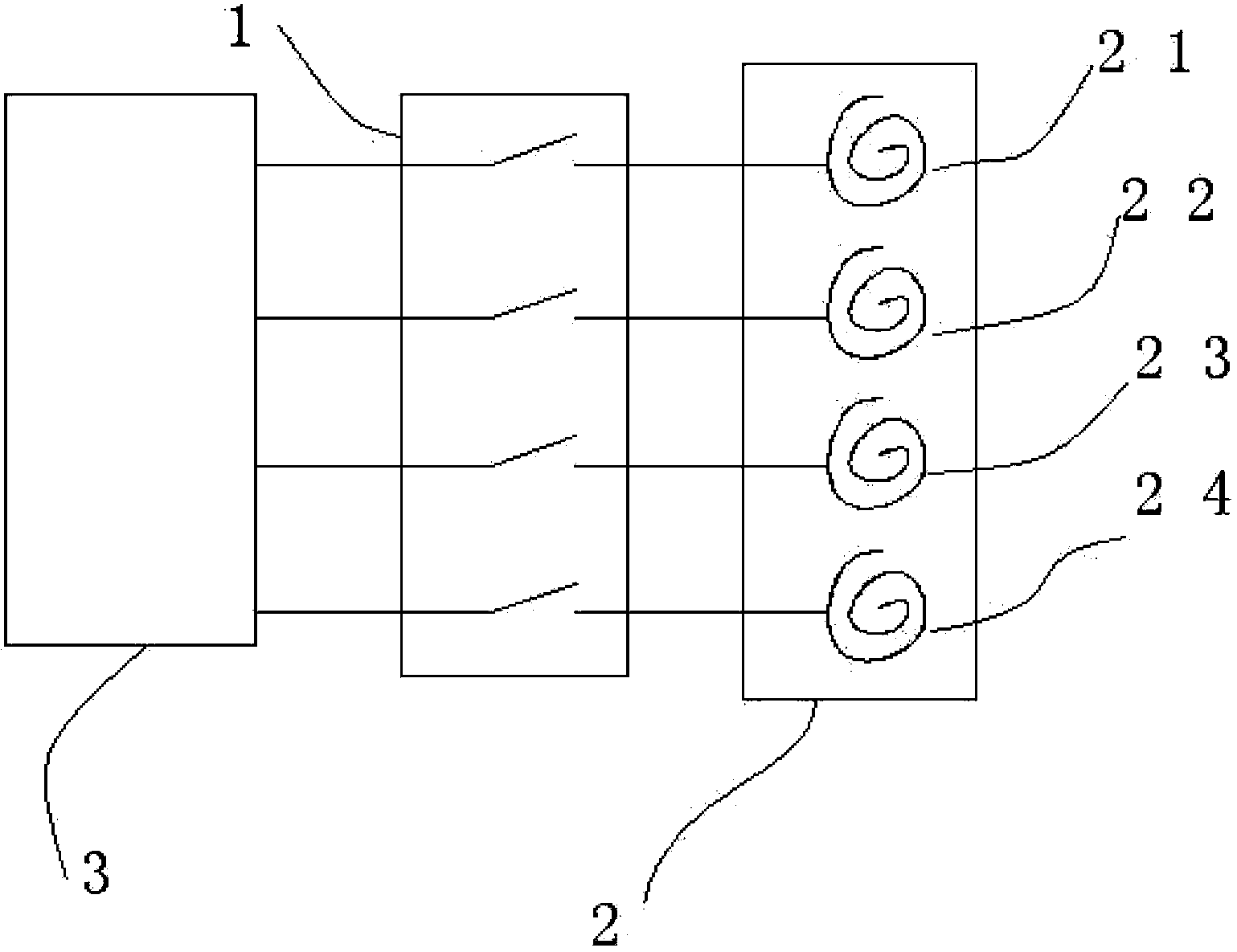

[0037] Such as figure 2 As shown, the present invention realizes the controllable closing / opening of the combined induction heating coil 2 by controlling the switch 1 through the timing control system 3 . The three-phase alternating current is rectified and filtered to obtain a relatively smooth direct current, and then the relay is used to control whether to send power to the inverter and the order of sending power to the inverter, thereby controlling the switching state and switching sequence of the coil circuit. The control of the relay is realized through the single-chip microcomputer control button board, so as to realize the controllable programming and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com