Green light emitting diode and manufacturing method thereof

A technology of light-emitting diodes and green light, which is applied to electrical components, circuits, semiconductor devices, etc., can solve the problems of reducing the luminous efficiency of green light-emitting diodes, reducing the luminous efficiency of green light-emitting diodes, and deteriorating electrical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

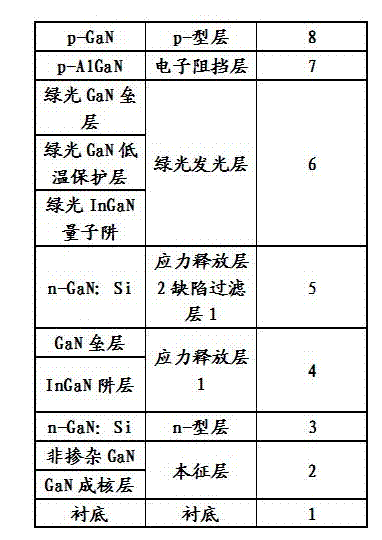

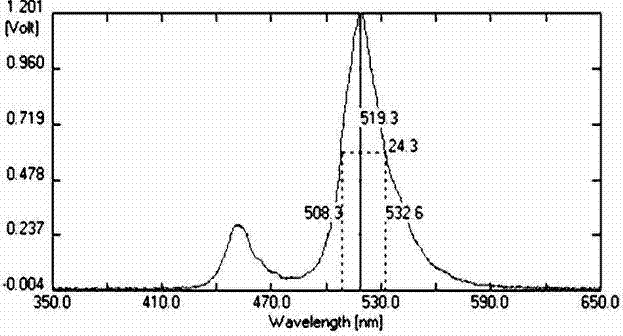

[0023] Such as figure 1 As shown, a high-brightness green light-emitting diode is grown in a MOVCD reaction chamber, and the sapphire substrate 1 is heated to above 1000°C, and the 2 As a carrier gas, treat for 880 seconds, then lower the substrate temperature to 500-600°C, put N 2 Switch to H 2 As a carrier gas, feed TMGa and NH3 to grow a GaN nucleation layer with a thickness of about 35nm; raise the substrate temperature to above 1000°C, use H2 as a carrier gas, and epitaxially grow an unintentionally doped GaN layer of about 1.5 microns; Raise the substrate temperature to above 1060°C, and still use H2 as the carrier gas to grow a 3 micron thick n-type Si-doped GaN layer with a doping concentration of -2.5E+17; reduce the substrate temperature to about 780°C , N2 as the carrier gas, using TEGa as the Ga source, grow an InGaN / GaN quantum well structure with a thickness of about 2000 angstroms on the n-type Si-doped GaN layer to control the stress, and finally control the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com