Phase-change magnetorheological material and preparation method thereof

A magnetorheological and phase change technology, applied in the direction of magnetic liquid, can solve the problems of magnetic particle sedimentation, affecting magnetorheological materials, high magneto-induced effect and high stability, etc., to achieve high stability and high magneto-induced effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0021] The preferred embodiment of the phase-change magnetorheological material of the present invention is:

[0022] It includes matrix material, magnetic particles, and surfactant. The matrix material includes paraffin wax mixed with white petrolatum at a mass ratio of 1.5:1-1:1.5. The magnetic particle is carbonyl iron powder. The surfactant is any of the following: One or more: stearic acid, oleic acid, sodium stearate, polyethylene glycol, silane coupling agent, Tween;

[0023] The matrix material, magnetic particles, and surfactants are proportioned according to the following parts by mass:

[0024] Matrix material: 38.2-69.1 parts;

[0025] Magnetic particles: 30-60 parts;

[0026] Surfactant: 0.9-1.8 parts.

[0027] The average particle diameter of the carbonyl iron powder is 0.1-50 μm.

[0028] The preparation method of the above-mentioned phase-change magnetorheological material of the present invention, its preferred embodiment comprises the following steps:

...

specific Embodiment 1

[0040] Get the raw material of following mass fraction:

[0041] Carbonyl iron powder (average particle size: 3.5 μm): 30%;

[0042] Surfactant: 0.9%

[0043] Paraffin: 34.55%

[0044] Vaseline: 34.55%

[0045] The preparation steps of materials involved in the present invention are as follows:

[0046] Add the paraffin wax, white petrolatum, and surfactant of the above quality into the conical flask, heat to 80°C to completely melt the three substances, and stir to mix evenly;

[0047] Weigh the above-mentioned carbonyl iron powder and add it to the Erlenmeyer flask;

[0048] Stop heating and continue to stir until the system cools down to room temperature. After the system solidifies, take out the sample, clean the experimental equipment and dry it.

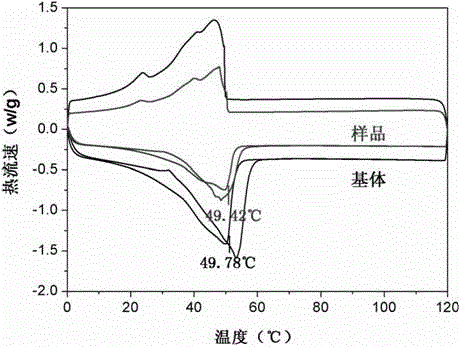

[0049] The phase transition temperature of the magnetorheological material matrix of the present invention is 49.78°C, which is moderate and easy to reach, and the phase transition can be realized by simple heating, see f...

specific Embodiment 2

[0051] Get the raw material of following mass fraction:

[0052] Carbonyl iron powder (average particle size: 3.5 μm): 40%;

[0053] Surfactant: 1.2%

[0054] Paraffin: 29.4%

[0055] Vaseline: 29.4%

[0056] Others are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com