High-temperature heated flocked silk banner and production process thereof

A production process and high-temperature heating technology, which is applied in decorative arts, flags/banners, instruments, etc., can solve the problems of rough appearance of pennants, and achieve the effect of beautiful and exquisite finished products, excellent workmanship and high appreciation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following embodiments illustrate the present invention more clearly and completely in conjunction with the accompanying drawings.

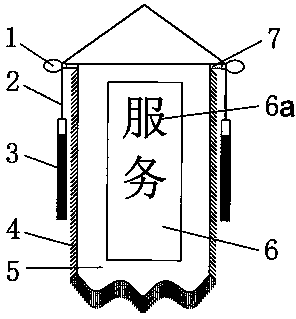

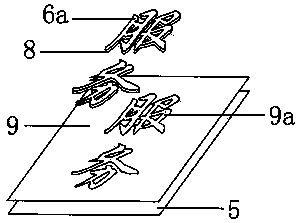

[0023] figure 1 A structural diagram of a high-temperature heating pennant pasted with fleece is shown. In the figure, this high-temperature heating velvet pennant includes a flag main body 5 on which a logo 6 is arranged. The flag main body 5 adopts a single layer of thickened deep red flannelette, the logo 6 adopts a single layer of yellow thickened flannelette, and a layer of translucent adhesive film 8 for bonding is arranged between the flag body 5 and the logo 6 . Both sides and the bottom of the main body of the flag 5 are provided with tassels 4 connecting the edges of the flag. The upper part of the flag main body 5 is provided with a flagpole 7 of glass fiber, and the two ends of the flagpole 7 are respectively provided with a flag head 1 injected by acrylic technology. The two ends of flagpole 7 respectively hang the flag ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com