Preparation method of permanent antistatic flame retardation multicolor polypropylene bulked filament

A bulked filament and antistatic technology, applied in the field of carpet yarn processing, can solve the problem of no industrial-scale production, and achieve the effects of improving spinnability, reducing usage, and reducing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] a. Preparation of antistatic flame retardant masterbatch: Weigh 83.5% polyoxyethylene ether grafted polypropylene (fine granular), 11% dodecyl phosphate methyldiethanolamine salt, 5.5% alkoxy hindered Put the amine flame retardant Flamestab NOR 116 into a high-speed mixer, disperse at high speed and heat up to 110°C, keep it for 1 minute, cool down and discharge to obtain antistatic flame retardant masterbatch;

[0036] b. Preparation of halogen-free flame retardant masterbatch: take 41% polypropylene chips, 47% compound halogen-free flame retardant (of which: 5% hindered amine flame retardant Flamestab NOR 116, 22.5% one-component intumescent Combustion agent CN-329, 2% trineopentyl glycol diphosphate, 15% phenylresorcinol diphosphate, 2.5% zinc acetylacetonate), 12% solubilizing and dispersing agent into the high-speed mixer , after being pre-mixed by a high-speed mixer, add it to a twin-screw extruder, and then melt, mix and granulate it at a temperature of 210°C to ...

Embodiment 2

[0045] a. Preparation of antistatic flame retardant masterbatch: preparation of antistatic flame retardant masterbatch: weigh 83.5% of polyoxyethylene ether grafted polypropylene (fine granular), 11% of dodecyl phosphate methyl diethanolamine salt , 5.5% alkoxy hindered amine flame retardant Flamestab NOR 116, put it into a high-speed mixer, disperse at a high speed and heat up to 110°C, keep it for 1 minute, cool down and discharge, and obtain antistatic flame retardant masterbatch;

[0046] b. Halogen-containing flame-retardant masterbatch: polypropylene flame-retardant masterbatch, containing 55% of the total amount of decabromodiphenylethane and antimony trioxide;

[0047] c. Spinning:

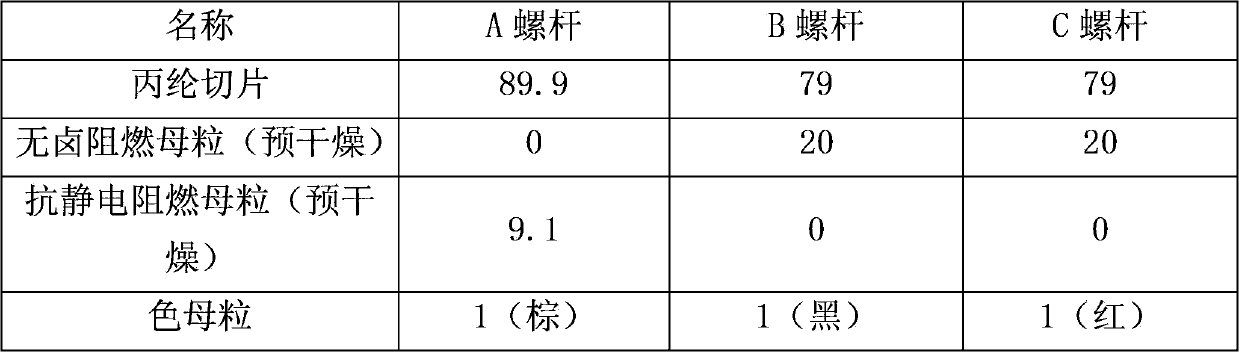

[0048] Raw material addition amount (weight%):

[0049]

[0050] Add the separately measured polypropylene chips and pre-dried flame retardant masterbatches, antistatic flame retardant masterbatches, and color masterbatches to the three feeding hoppers of the three-screw BCF spinning u...

Embodiment 3

[0055]a. Preparation of antistatic flame retardant masterbatch: Weigh 83.5% polyoxyethylene ether grafted polypropylene (fine granular), 11% dodecyl phosphate methyldiethanolamine salt, 5.5% alkoxy hindered Put the amine flame retardant FlamestabNOR 116 into a high-speed mixer, disperse at a high speed and heat up to 110°C, keep it for 1 minute, cool down and discharge to obtain antistatic flame retardant masterbatch;

[0056] b. Preparation of halogen-free flame retardant masterbatch: take 41% polypropylene chips, 47% compound halogen-free flame retardant (of which: 5% hindered amine flame retardant Flamestab NOR 116, 22.5% one-component intumescent Combustion agent CN-329, 2% trineopentyl glycol diphosphate, 15% phenylresorcinol diphosphate, 2.5% zinc acetylacetonate), 12% solubilizing and dispersing agent into the high-speed mixer , after being pre-mixed by a high-speed mixer, add it to a twin-screw extruder, and then melt, mix and granulate it at a temperature of 210°C to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com