Method for extracting valuable metals and refining zinc sulphate monohydrate from zinc-containing waste material

A technology of valuable metals and zinc sulfate, applied in the direction of improvement of process efficiency, etc., can solve the problems of complex impurity removal industry for leachate, high equipment cost and energy consumption, and large process energy consumption, etc., to achieve high recovery rate, convenient operation, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments:

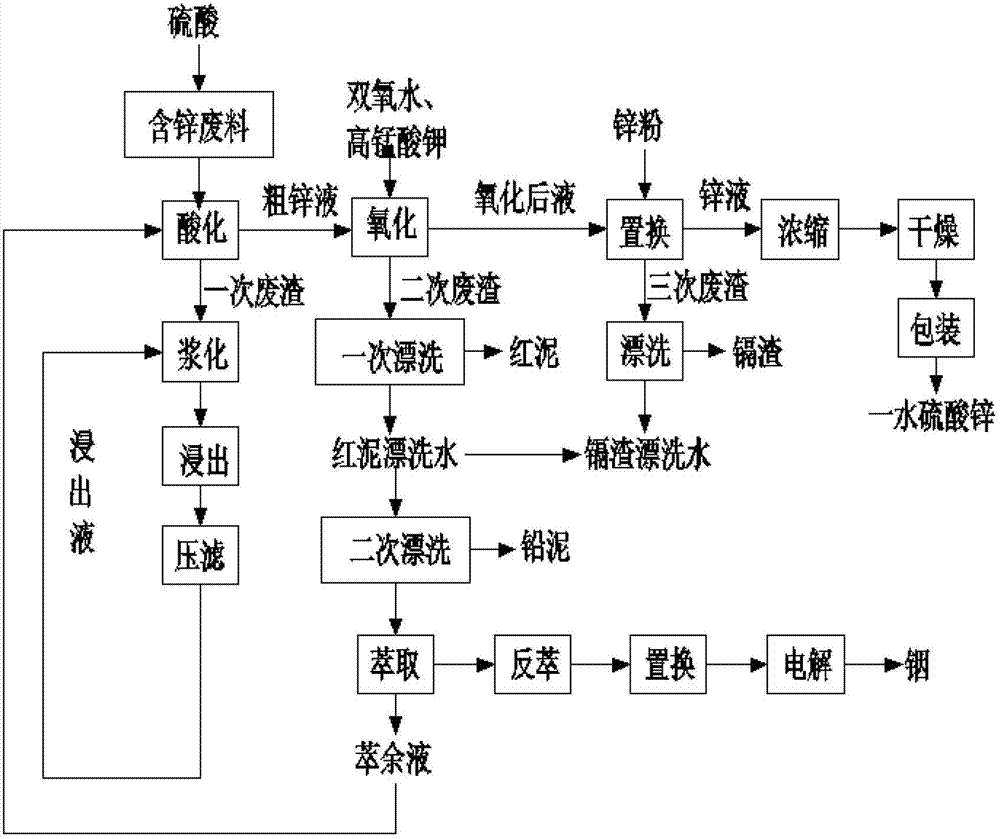

[0018] Please refer to figure 1 , a method for extracting valuable metals and refining zinc sulfate monohydrate from zinc-containing waste provided by the present invention, including refining zinc sulfate monohydrate and extracting valuable metals such as cadmium, lead and indium, wherein the The process of extracting zinc sulfate monohydrate includes steps such as acidification, oxidation, zinc replacement, concentration, drying and packaging; the process of extracting cadmium includes steps such as acidification, oxidation, replacement, and rinsing of cadmium slag; the process of extracting lead includes acidification , oxidation, primary rinsing, secondary rinsing and other steps; the process of extracting indium includes acidification, oxidation, primary rinsing, secondary rinsing, extraction, stripping, ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com