Method for preparing lepirudin

A technology of lepirudin and coupling method, applied in the field of peptide synthesis, can solve the problems of low yield, difficult purification, high energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

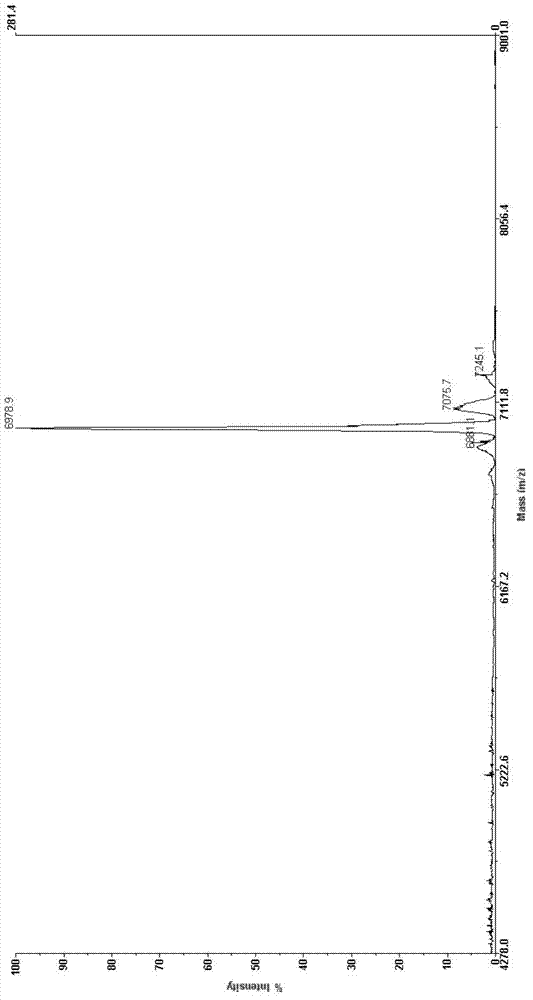

Image

Examples

preparation example Construction

[0119] The raw materials and reagents used in the method for preparing lepirudin provided by the present invention can be purchased from the market.

[0120] The meanings of the abbreviations used in the method for preparing Lepirudin provided by the present invention are as follows.

[0121] Fmoc 9-fluorenylmethoxycarbonyl

[0122] Boc tert-butoxycarbonyl

[0123] tBu tert-butyl

[0124] Trt Trityl

[0125] NMP N-Methylpyrrolidone

[0126] DMSO dimethyl sulfoxide

[0127] DMF N,N-Dimethylformamide

[0128] DCM dichloromethane

[0129] DBLK 20% Hexahydropyridine / DMF Solution

[0130] DIC N,N-Diisopropylcarbodiimide

[0131] DIPEA N,N-Diisopropylethylamine

[0132] DMAP 4-dimethylaminopyridine

[0133] PYBOP Benzotriazol-1-yl-oxytripyrrolidinyl hexafluorophosphate

[0134] TBTU O-benzotriazole-N,N,N',N'-tetramethyluronium tetrafluoroboric acid

[0135] HOBT 1-Hydroxybenzotriazole

[0136] TFE trifluoroethanol

[0137] TFA trifluoroacetic acid

[0138] EDT 1,2-eth...

Embodiment 1

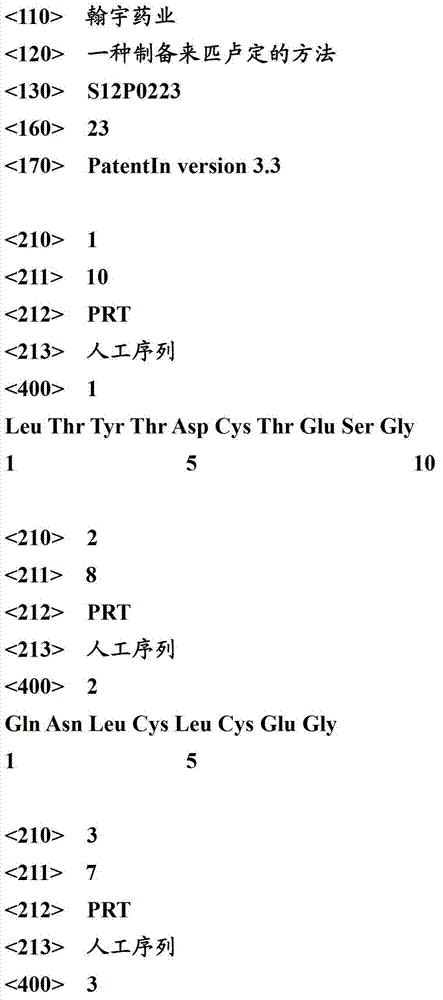

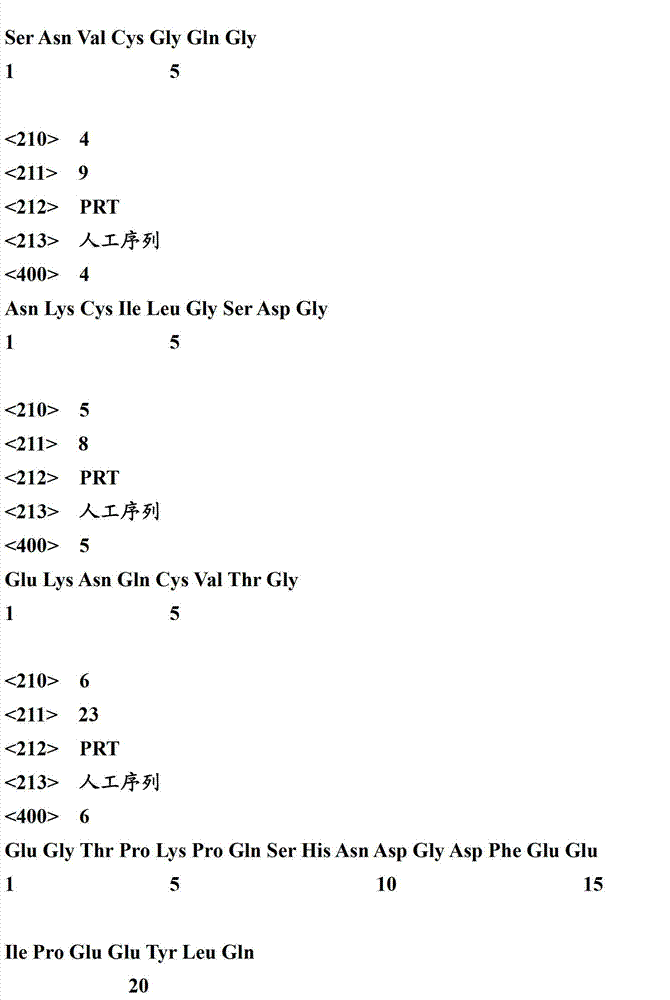

[0153] Fragment 1 (sequence shown in SEQ ID NO:1)

[0154] FMOC-Leu-Thr(tBu)-Tyr(tBu)-Thr(tBu)-Asp(OtBu)-Cys(Trt)-Thr(tBu)-Glu(OtBu)-Ser(tBu)-Glycine-2-CTC Peptide Preparation of resin

[0155] Weigh 10 g of 2-CTC resin with a substitution degree of 0.5 mmol / g, add it to a solid-phase reaction column, wash it twice with DMF, and swell the resin with DMF for 30 minutes, then take 1.8 g of Fmoc-Gly-OH and dissolve it in DMF. Add 2.7mL DIPEA in ice-water bath to activate, add to the above-mentioned reaction column filled with resin, react for 60min, drain, wash three times, block with methanol three times, add 25mL each time, each time for 10min, and wash with DMF for 6 Second-rate. Fmoc protection was removed with DBLK, followed by 6 washes with DMF.

[0156] Dissolve 5.74g Fmoc-Ser(tBu)-OH, 2.43g HOBt, and 3.51ml DIC in a mixed solution of DCM and DMF with a volume ratio of 1:1, add it to a solid-phase reaction column, and react at room temperature for 2h (the end point of t...

Embodiment 2

[0208] Fragment 1 (sequence shown in SEQ ID NO:1)

[0209] FMOC-Leu-Thr(tBu)-Tyr(tBu)-Thr(tBu)-Asp(OtBu)-Cys(Trt)-Thr(tBu)-Glu(OtBu)-Ser(tBu)-Gly-2-CTC peptide Preparation of resin

[0210] Weigh 10 g of 2-CTC resin with a substitution degree of 0.5 mmol / g, add it to a solid-phase reaction column, wash it twice with DMF, and swell the resin with DMF for 30 minutes, then take 1.8 g of Fmoc-Gly-OH and dissolve it in DMF. After adding 2.7mL DIPEA to activate in ice-water bath, add to the above-mentioned reaction column with resin, after 60min of reaction, drain, wash three times, block with methanol three times, add 25mL each time, each time for 10min, then wash with DMF for 6 Second-rate. Fmoc protection was removed with DBLK, followed by 6 washes with DMF.

[0211] Dissolve 5.74g Fmoc-Ser(tBu)-OH, 2.43g HOBt, and 3.51ml DIC in a mixed solution of DCM and DMF with a volume ratio of 1:1, add it to a solid-phase reaction column, and react at room temperature for 2h (the end poi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com