Efficient flocculent precipitate purification method for polymetallic ore benefication wastewater

A technology for beneficiation wastewater and polymetallic ore, which is applied in flocculation/sedimentation water/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. and other problems, to achieve the effect of good flocculation and sedimentation, rapid separation of mud and water, and compact and stable flocs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The tungsten-bismuth beneficiation wastewater was treated with polysilicate aluminum ferric sulfate flocculants with different ratios.

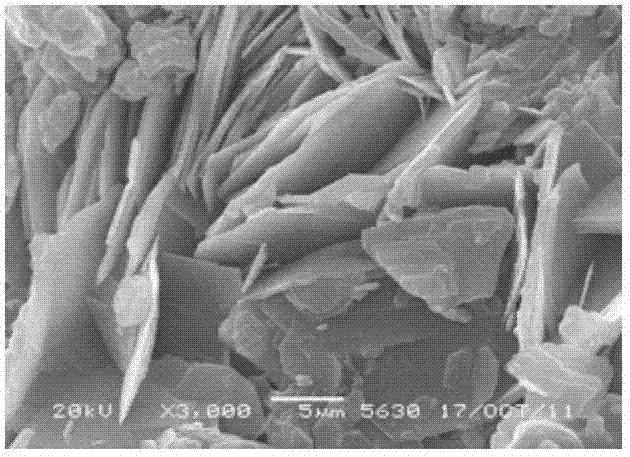

[0025] Dilute water glass to SiO 2 The mass percentage is 7%, slowly added to the rapidly stirred dilute H 2 SO 4 In the solution, the pH value is controlled to be 3~3.5. After polymerizing for a period of time at room temperature, a certain amount of aluminum sulfate octadecahydrate is added therein, and stirred rapidly to make it fully polymerized; subsequently, a certain amount of ferrous sulfate heptahydrate is dissolved in dilute H 2 SO 4 The oxidized solution in the solution is quickly mixed with the above-mentioned solution at 40-60°C, kept at the temperature for polymerization for a period of time, diluted with distilled water until the total Fe concentration is 0.15mol / L, and the polysilicate aluminum ferric sulfate flocculant ( figure 1 ).

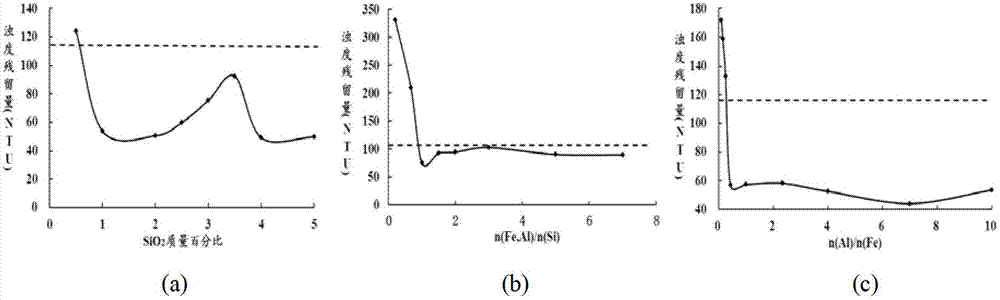

[0026] SiO in retaining flocculant 2 Mass percentage=0.5%~5%, the ratio of the ...

Embodiment 2

[0028] Treatment of tungsten-bismuth beneficiation wastewater with polysilicate aluminum iron sulfate flocculant.

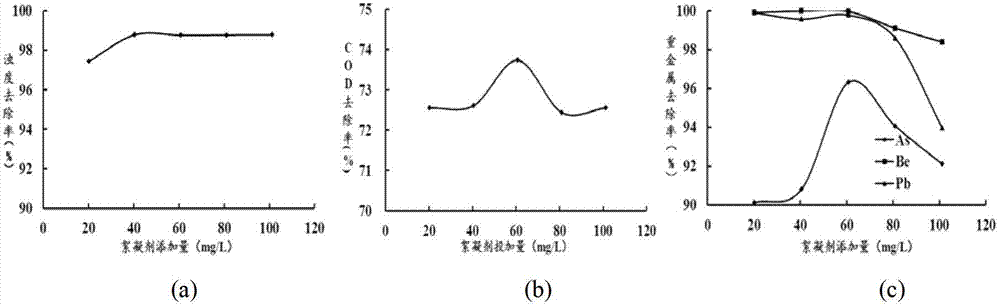

[0029]According to the preparation method of the polysilicate aluminum ferric sulfate flocculant in Example 1, the polysilicate aluminum ferric sulfate flocculant was obtained. Add 20.25, 40.5, 60.75, 81, 101.25 mg / L in sequence to the tungsten-bismuth mineral processing wastewater with pH 7.83, COD 280 mg / L, turbidity 7175 NTU, and concentrations of heavy metals As, Be, and Pb respectively 0.92, 0.49, and 5.78 mg / L (Based on the concentration of aluminum in the flocculant in wastewater) polysilicate aluminum ferric sulfate flocculant, stir rapidly at a speed of 200r / min for 1.5min, then stir slowly at a speed of 40r / min for 15min, and take the supernatant after standing for 30min to test. The test results showed that ( image 3 ), when 60.75mg / L (based on the concentration of aluminum in the flocculant in the wastewater) polysilicate aluminum iron sulfate floc...

Embodiment 3

[0031] Tungsten-bismuth beneficiation wastewater was treated by two-stage flocculation-sedimentation of polysilicate aluminum ferric sulfate and polyacrylamide.

[0032] According to the preparation method of the polysilicate aluminum ferric sulfate flocculant in Example 1, the polysilicate aluminum ferric sulfate flocculant was obtained. In the tungsten-bismuth beneficiation wastewater with a pH of 7.83, a COD of 280mg / L, a turbidity of 7175NTU, and concentrations of heavy metals As, Be, and Pb of 0.92, 0.49, and 5.78mg / L, add 60.75mg / L to the wastewater (based on the concentration of aluminum in the flocculant in wastewater) polysilicate aluminum ferric sulfate flocculant; stir rapidly at a speed of 200r / min for 1.5min, then add polyacrylamide to make its concentration in wastewater reach 2.5mg / min L; after settling for 5 minutes, the residual turbidity is 198 NTU; after 15 minutes, the residual turbidity is 89 NTU. After SV30 evaluation (the mixed solution was placed in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com