Copper-graphene composite material and method for preparation of graphene film on copper-based metal surface

A composite material and graphene technology, which is applied to copper-metal composite materials and their preparation, and the preparation of graphene films on copper-based metal surfaces can solve the problems of complex process, difficult control, and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

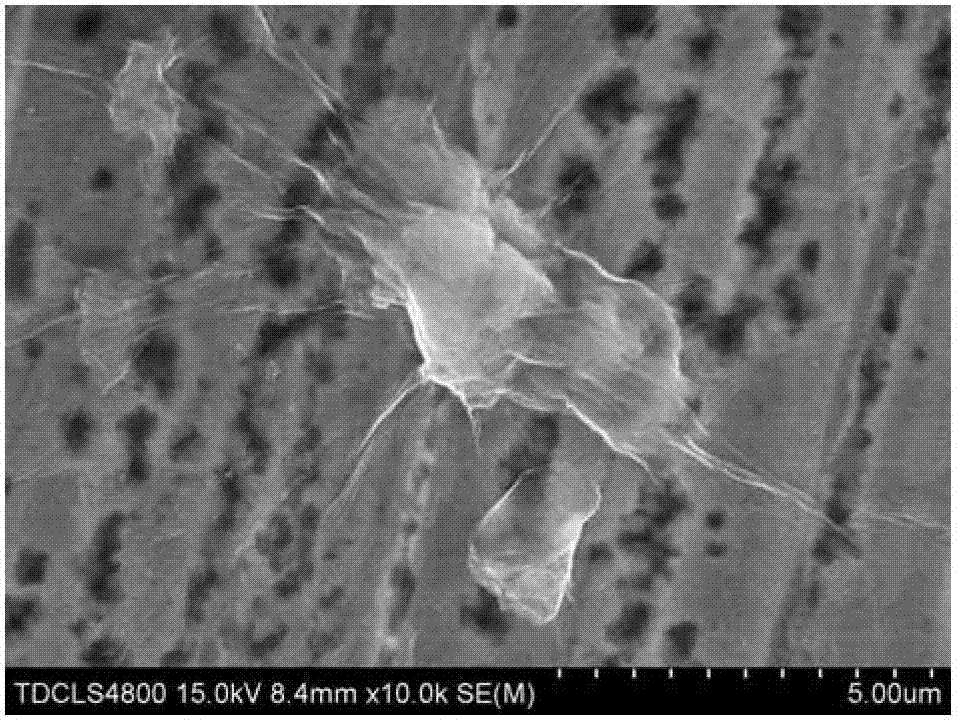

[0016] Embodiment 1: A novel preparation method of graphene thin film, utilizes oxidation-reduction method in combination with pulling coating method to prepare graphene on copper surface.

[0017] Take by weighing 3g particle size and be the graphite powder of 200 mesh, after putting into beaker, add 90ml concentration and be the concentrated H of 98wt%. 2 SO 4 , and kept stirring on a magnetic stirrer, slowly added KMnO 4 12g of powder, stirred in an ice bath for 1.5h, then raised the temperature to 30°C, stirred in a constant temperature water bath for 1h, then raised the temperature to 70°C. After 15 minutes, slowly add 250ml of deionized water to the reaction solution with a pear-shaped bottle for 1.5 hours. After 30 minutes of reaction, quickly add 500ml of deionized water and 30ml of H 2 o 2 , the solution was golden yellow. After stirring and standing still, remove the solid solution in the lower layer, wash it with dilute HCl 5wt%, centrifuge it, and dry it at 80°...

Embodiment 2

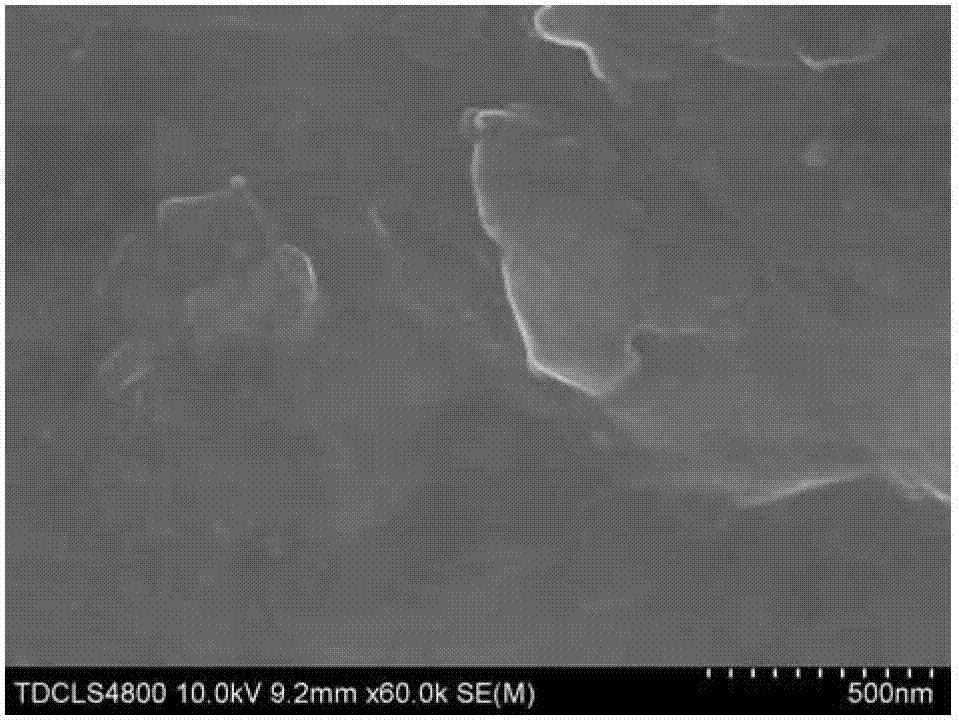

[0023] Embodiment 2: A novel preparation method of graphene film, which utilizes redox method in combination with pull coating method to prepare graphene on copper surface.

[0024] Weigh 3g of natural graphite flakes, put them into a beaker, add 120ml concentration of 98wt% concentrated H 2 SO 4 , and kept stirring on a magnetic stirrer, slowly added KMnO 4 15g of powder was stirred on an ice bath for 1.5h, then the temperature was raised to 40°C, and after stirring in a constant temperature water bath for 1h, the temperature was raised to 60°C. After 15 minutes, slowly add 250ml of deionized water to the reaction solution with a pear-shaped bottle for 1.5 hours. After 30 minutes of reaction, quickly add 500ml of deionized water and 40ml of H 2 o 2 , the solution was golden yellow. After stirring and standing still, remove the solid solution in the lower layer, wash it with dilute HCl 5wt%, centrifuge it, and dry it at 80°C to obtain graphite oxide (brown black), grind it...

Embodiment 3

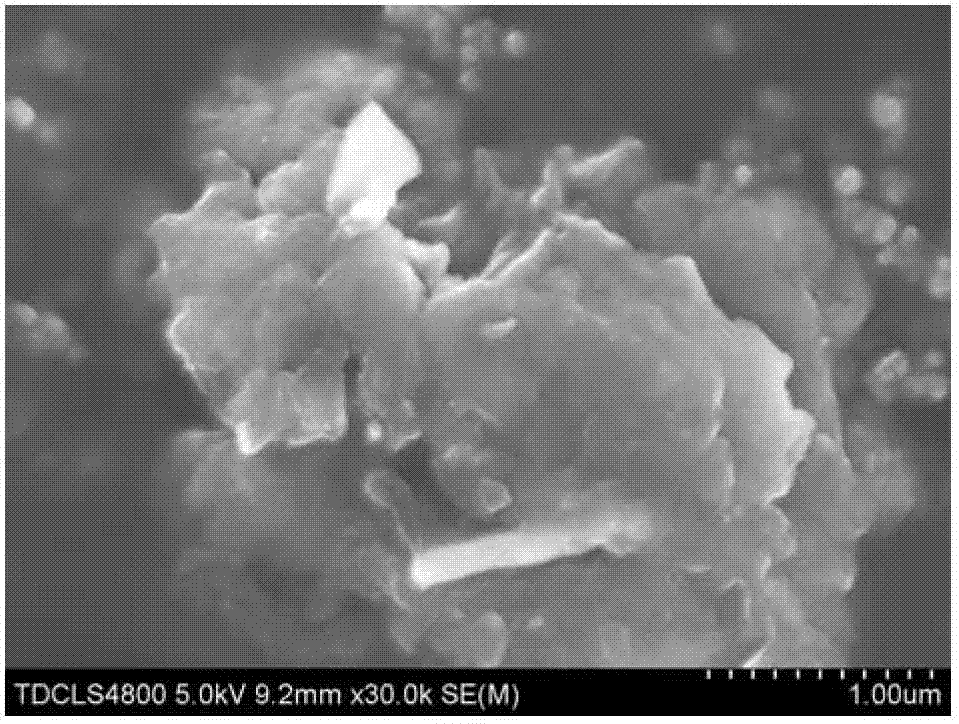

[0029] Embodiment 3: A novel preparation method of graphene film, which utilizes redox method in combination with pull coating method to prepare graphene on copper surface.

[0030] Take by weighing 3g particle size and be the graphite powder of 200 mesh, after putting into beaker, add 90ml concentration and be the concentrated H of 98wt%. 2 SO 4 , and kept stirring on a magnetic stirrer, slowly added KMnO 4 12g of powder, stirred in an ice bath for 1.5h, then raised the temperature to 30°C, stirred in a constant temperature water bath for 1h, then raised the temperature to 70°C. After 15 minutes, slowly add 250ml of deionized water to the reaction solution with a pear-shaped bottle for 1.5 hours. After 30 minutes of reaction, quickly add 500ml of deionized water and 30ml of H 2 o 2 , the solution was golden yellow. After stirring and standing still, remove the solid solution in the lower layer, wash it with dilute HCl 5wt%, centrifuge it, and dry it at 80°C to obtain grap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com