Bonding agent for low-melting high-strength microcrystalline alumina ceramic grinding tool and preparation method thereof

A kind of alumina ceramic and binder technology, which is applied in abrasives, manufacturing tools, metal processing equipment, etc., to achieve the effect of small ion radius, strong reaction ability and good grinding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] molar ratio SiO 2 :Al 2 o 3 :B 2 o 3 :Na 2 O: ZnO: LiF = 46.0: 7.5: 26.0: 16.5: 2.0: 2.0 Weigh the raw material SiO 2 , γ-Al 2 o 3 (nanoscale), H 3 BO 3 、Na 2 CO 3 , ZnO (nanoscale) and LiF, put them into a mortar and mix them evenly, then put them into an alumina crucible, and then calcinate them in a high-temperature resistance furnace with a heating rate of 5°C / min, keep them at 1250°C for 4 hours, take them out Water quenching, drying the surface moisture of the glass frit, putting it into a ball mill, dry grinding at a speed of 400r / min for 1 hour, and sieving to obtain a powdered vitrified bond with a particle size of 5-10 μm.

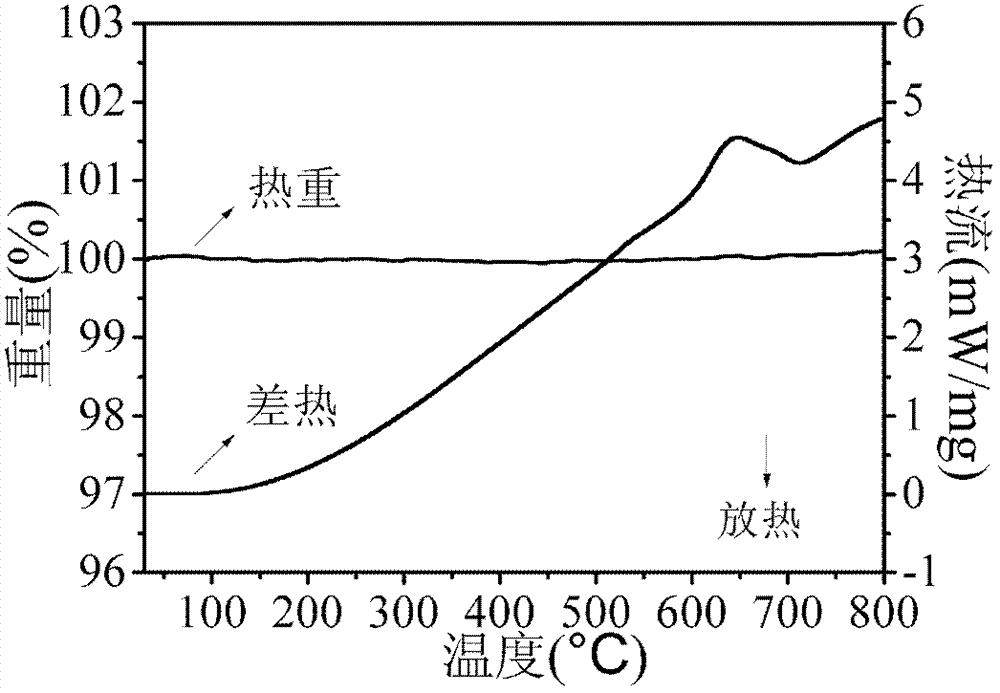

[0026] The thermogravimetric-differential heat (TG-DSC) curve of gained binder is as follows figure 1 , indicating that there is no weight gain or weight loss when the binder is heated to 800°C, so the properties of the prepared binder are relatively stable; the DSC curve shows that the melting range of the product is wide, fro...

Embodiment 2

[0028] SiO in molar ratio 2 : Al 2 o 3 :B 2 o 3 :Na 2 O: ZnO: LiF = 46.0: 7.5: 26.0: 16.5: 2.0: 2.0 Weigh the raw material SiO 2 , γ-AlOOH (nanoscale), H 3 BO 3 、Na 2 CO 3 , ZnO (nanoscale) and LiF, put them into a mortar and mix them evenly, then put them into an alumina crucible, and then calcinate them in a high-temperature resistance furnace at a heating rate of 4°C / min, keep them at 1200°C for 4 hours, take out Water quenching, drying the surface moisture of the glass frit, putting it into a ball mill, dry grinding at a speed of 450r / min for 40 minutes, and obtaining a powdered vitrified bond with a particle size of 8-10 μm after sieving. , the melting range of the obtained bonding agent is 587.3-720° C., and the flexural strength of the microcrystalline alumina ceramic abrasive test strip after firing at 750° C. is 83.12-93.73 MPa.

Embodiment 3

[0030] molar ratio SiO 2 : Al 2 o 3 :B 2 o 3 :Na 2 O: Li 2 O: ZnO: LiF = 46.0: 7.5: 26.0: 14.5: 2.0: 2.0: 2.0 Weigh the raw material SiO 2 , γ-Al 2 o 3 (nanoscale), H 3 BO 3 、Na 2 CO 3 , Li 2 CO 3 , ZnO (nano-level) and LiF, prepared according to the method of Example 1, the melting range of the obtained binder is 603.4-671 ° C, and the flexural strength of the microcrystalline alumina ceramic abrasive test strip after firing at 725 ° C is 86.61 -103.32MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com