Broach

A technology for cutting teeth and heads, which is applied in the broach field of internal tooth processing of intelligent gear ratchet ruler embedded parts, can solve problems such as difficult processing, achieve high processing efficiency, improve economic benefits, and enhance market competitiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

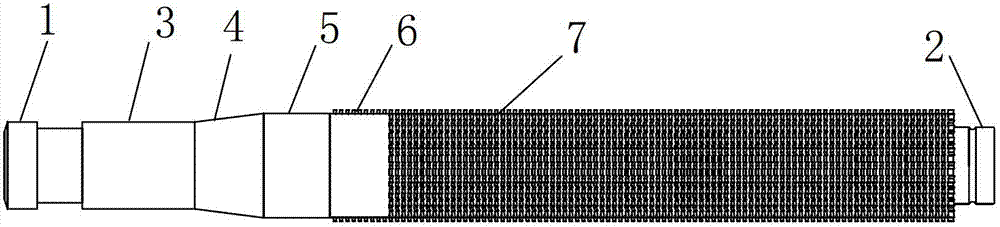

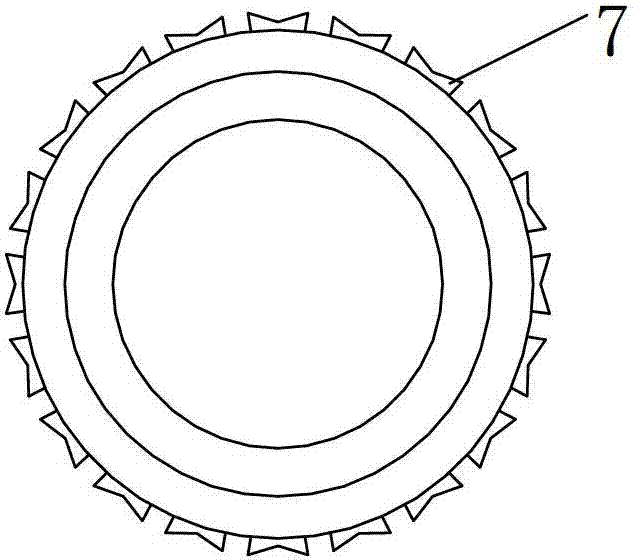

[0014] Such as figure 1 and figure 2 As shown, a broach of the present invention includes a head 1 and a tail 2. From the head 1 to the tail 2, there are neck 3 for connection, transition cone 4, leading part 5 for guiding and finishing cutting Working cutting teeth, the head 1 is used to clamp the broach and transmit power, the transition cone 4 is used to introduce the leading part 5 of the broach into the workpiece, the cutting teeth include inner ring cutting teeth 6 and pawl cutting teeth 7, the inner ring cutting teeth There are 10-20 rows of teeth 6, and 60-100 rows of pawl cutting teeth 7, and the tooth shape size of each row of cutting teeth increases sequentially from the cutting end to the cutting end.

[0015] In this embodiment, the pawl cutting teeth 7 are in the shape of a dovetail, and there are trapezoidal grooves between the dovetail-shaped cutting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com