Condensation-type defogging device

A demisting device, condensing technology, applied in the field of industrial spray cleaning, can solve the problems of not being able to meet the requirements of spray cleaning and demisting, high maintenance and cost, and ineffective effect, and achieve better demisting effect and automation High degree, no pollution residue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

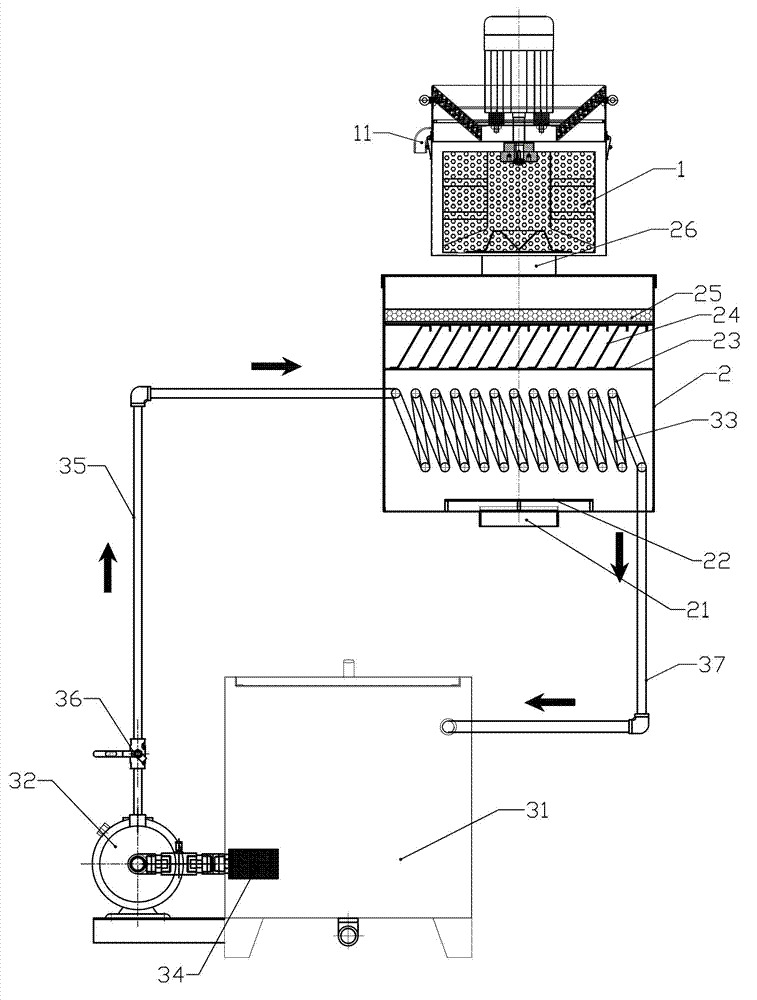

[0024] Such as figure 1 with figure 2 as shown,

[0025] A condensing type demisting device includes three parts including a demister 1, a condensate recovery box 2 and a cold cutting water circulation system, wherein the demister is a prior art and can be obtained from the market.

[0026] The cooling water circulation system is a self-closed water circulation system composed of a cold cut water tank 31, a self-priming pump 32, and a heat exchange spiral pipe 33 connected end to end through pipes and valves. Specifically, it consists of a cold cut water tank 31, a filter before the pump 34, and a Suction pump 32, cold cut water inlet pipe 35, water inlet pipe ball valve 36, heat exchange spiral pipe 33, return water overflow pipe 37, the cold cut water tank is used to temporarily store the cooling medium - water, and heat through the heat exchange spiral pipe exchange, forming an independent circulation system in which cold water runs automatically.

[0027] Condensation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com