High-voltage lithium battery cathode material doped with trace amount of tungsten and preparation method thereof

A technology for high-voltage lithium batteries and positive electrode materials, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of low electronic conductivity of lithium iron phosphate, difficulty in meeting high-current charging and discharging, and poor price of cobalt, etc., to achieve charging Improved discharge cycle performance, improved cycle stability, and uniform voltage changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

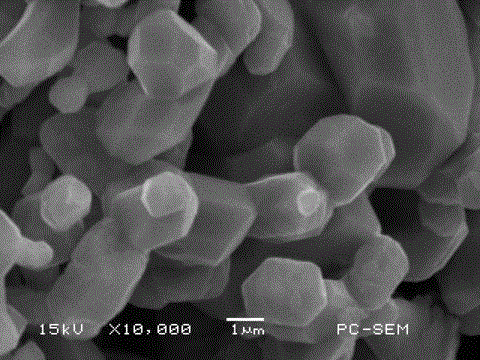

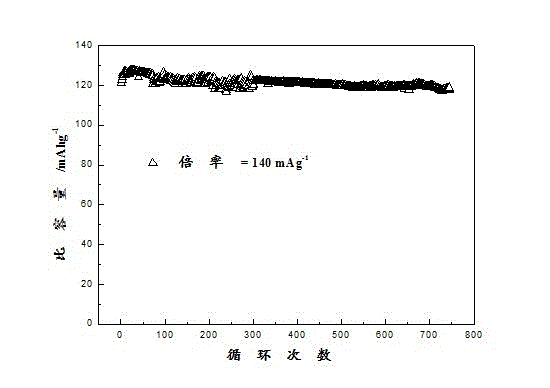

Embodiment 1

[0030] Preparation of LiNi 0.5 mn 1.4985 W 0.001 o 4 . Weigh and dissolve 0.105 mol lithium acetate, 0.05 mol nickel acetate, 0.14985 mol manganese acetate, 0.0001 mol tungsten hexachloride and 0.315 mol ammonium oxalate in 500 ml deionized water at a molar ratio of 1.05:0.5:1.4985:0.001:3. Control the constant heating and stirring at 60°C, and finally obtain a viscous wet gel, place the wet gel in a vacuum drying oven, and dry it in a vacuum at 90°C to obtain a grass-green xerogel, and then quickly transfer the xerogel to a horse In a Furnace, pre-sinter at 400 °C for 6 hours to obtain a pre-sintered product, cool to room temperature and then grind, then perform secondary sintering at 700 °C for 10 hours, cool to room temperature, and grind to obtain a doped trace tungsten element High-voltage lithium battery cathode material LiNi 0.5 mn 1.4985 W 0.001 o 4 . The prepared material was assembled into a button battery, tested at a constant current charge and discharge...

Embodiment 2

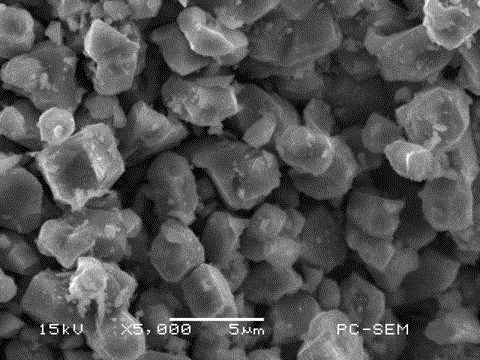

[0032] Preparation of LiNi 0.5 mn 1.4925 W 0.005 o 4 . Weigh 0.105 mol of lithium acetate, 0.05 mol of nickel acetate, 0.14925 mol of manganese acetate, 0.0005 mol of tungsten hexachloride, and 0.315 mol of ammonium oxalate in a molar ratio of 1.05:0.5:1.4925:0.005:3 and dissolve them in 500 ml of deionized water. Control the constant heating and stirring at 50 ℃, and finally get the wet gel, put the wet gel in a vacuum drying oven, and dry it in vacuum at 100 ℃ to get a grass-green xerogel, and then quickly transfer the xerogel to the muffle furnace , pre-sintered at 500 °C for 5 hours to obtain a pre-sintered product, cooled to room temperature and then ground, and then carried out secondary sintering at 900 °C for 8 hours, cooled to room temperature, ground, and finally obtained a high-voltage lithium doped with trace tungsten elements Battery cathode material LiNi 0.5 mn 1.4925 W 0.005 o 4 . The prepared material was assembled into a button battery, and tested at...

Embodiment 3

[0034] Preparation of LiNi 0.5 mn 1.4865 W 0.009 o 4 . Weigh 0.105 mol of lithium acetate, 0.05 mol of nickel acetate, 0.14865 mol of manganese acetate, 0.0009 mol of tungsten hexachloride, and 0.315 mol of ammonium oxalate in a molar ratio of 1.05:0.5:1.4865:0.009:3 and dissolve them in 500 ml of deionized water. Control the constant heating and stirring at 80 ℃, and finally get the wet gel, put the wet gel in a vacuum drying oven, and dry it in vacuum at 80 ℃ to get a grass-green xerogel, and then quickly transfer the xerogel to the muffle furnace , pre-sintered at 600 °C for 4 hours to obtain a pre-sintered product, cooled to room temperature and then ground, and then carried out secondary sintering at 1000 °C for 6 hours, cooled to room temperature, ground, and finally obtained a high-voltage lithium doped with trace tungsten elements Battery cathode material LiNi 0.5 mn 1.4865 W 0.009 o 4. The prepared material was assembled into a button battery, and tested at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com