X-ETFE (crosslinked ethylene-tetrafluoroethylene) insulating wire or cable with spiral stripe identifications for aerospace and preparation process for insulating wire or cable

An X-ETFE, aerospace technology, used in insulated cables, marked conductors/cables, insulated conductors, etc., to achieve good UV resistance and reduce vehicle weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

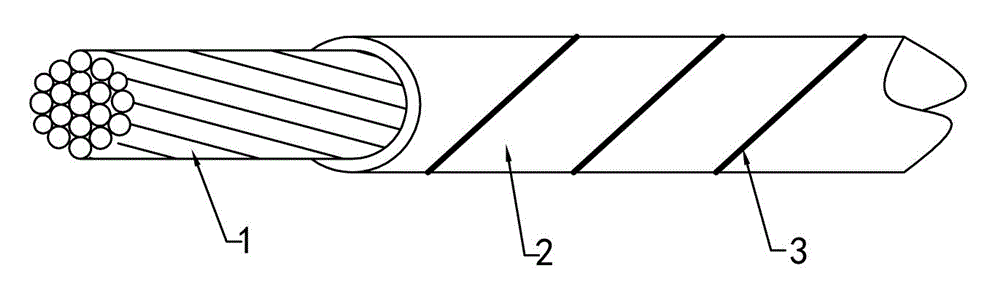

[0030] Such as figure 1 As shown, it is a schematic structural diagram of the spiral stripe marking wire (including a single insulated core wire, without a sheath layer) of the present invention, and the conductor 1 formed by twisting is covered with a double-layer insulation layer composed of an inner and outer insulation layer. Layer 2, with a spiral stripe logo 3 printed on the outside of the insulating layer 2;

[0031] Its preparation process is as follows:

[0032] 1) Conductor stranding: use annealed silver-plated (nickel) copper conductors for stranding with a pitch ratio of less than 20;

[0033] 2) Insulation layer extrusion: inner and outer insulation layers are co-extruded (extrusion temperature is 245-315°C) to form a double-layer insulation layer. The rubber material of the insulation layer is X-ETFE, and the concentricity of the insulation layer is 85%. The thinnest point of the layer is 0.08mm, and the thinnest point of the outer insulating layer is 0.10mm; ...

Embodiment 2

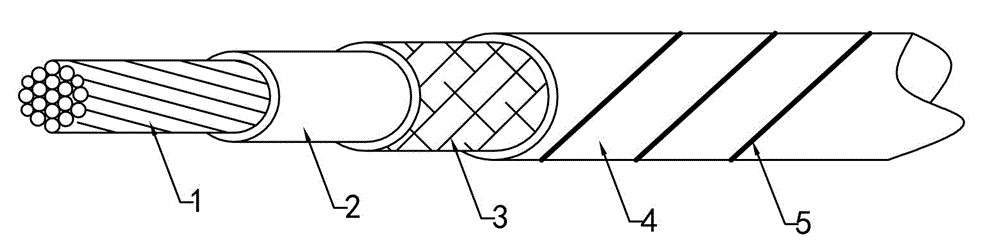

[0039] Such as figure 2 As shown, it is a structural schematic diagram of the spiral stripe marking cable (composed of a single insulated core wire, a shielding layer and a sheath layer) of the present invention, the conductor 1 formed by twisting is covered with an insulating layer 2, and the insulating layer 2 is provided with a shielding layer 3 outside, and a sheath layer 4 is covered outside the shielding layer 3, and a spiral stripe logo 5 is printed on the sheath layer 4.

[0040] Its preparation process is as follows:

[0041] 1) Conductor stranding: use annealed silver-plated (nickel) copper conductors for stranding with a pitch ratio of less than 20;

[0042] 2) Extrusion of insulating layer: high-temperature extrusion of single-layer insulation (extrusion temperature is 245-300°C), the compound of the insulating layer is X-ETFE, the concentricity of the insulating layer is 85%, and the thinnest point of the insulating layer is 0.13mm;

[0043] 3) Carry out radiat...

Embodiment 3

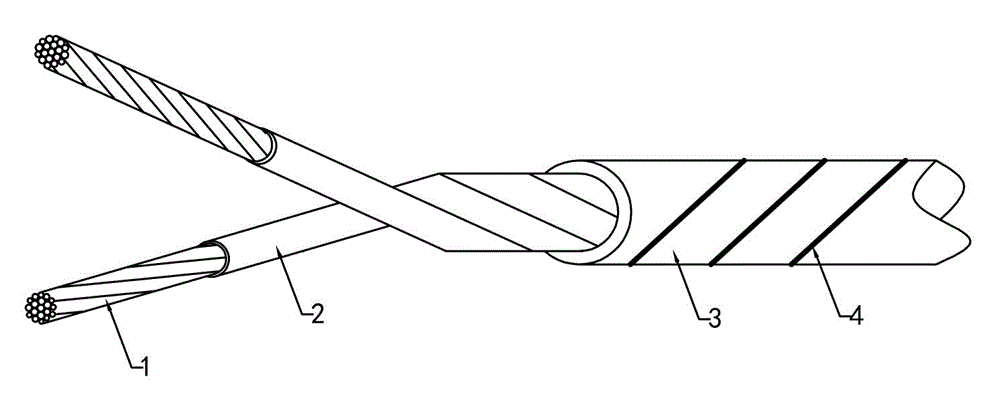

[0051] Such as image 3 As shown, it is a structural schematic diagram of the spiral striped marking cable (composed of two insulated core wires and a sheath layer) of the present invention, the conductor 1 formed by twisting is covered with an insulating layer 2, and the conductor 1 and the insulating layer 2 An insulated core wire is formed, and the insulating layer 2 is covered with a sheath layer 3 , and a spiral stripe logo 4 is printed on the surface of the sheath layer 3 .

[0052] Its preparation process is as follows:

[0053] 1) Conductor stranding: use annealed silver-plated (nickel) copper conductors for stranding with a pitch ratio of less than 20;

[0054] 2) Extrusion of insulating layer: high-temperature extrusion of single-layer insulation (extrusion temperature is 245-300°C), the compound of the insulating layer is X-ETFE, the concentricity of the insulating layer is 83%, and the thinnest point of the insulating layer is 0.13mm;

[0055] 3) Carry out radiat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com