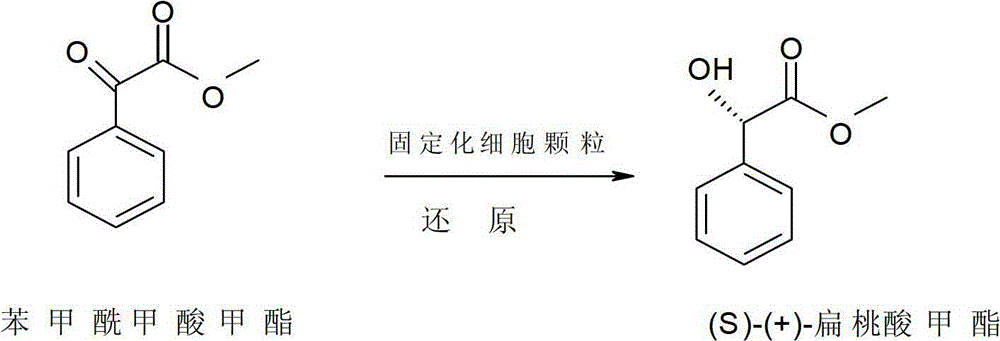

Method for preparing methyl (S)-(+)-mandelate by microbial transformation of methyl benzoylformate

A technology of benzoylformic acid and methyl mandelic acid, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as the decline of biotransformation efficiency, and achieve easy large-scale industrial production and mild reaction conditions. , the effect of increasing conversion volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Slant culture: Inoculate CGMCC No.2230 strains on the slant medium and culture at 30°C for 4-6 days. Slant medium composition: wort juice 10g / L, yeast powder 3g / L, peptone 5g / L, glucose 10g / L, agar 20g / L, natural pH value, solvent is water, sterilized at 121°C for 20min, cooled after sterilization Make a bevel.

[0032] Seed cultivation and fermentation: Both the seed and fermentation medium use liquid medium, the composition is glucose 30g / L, yeast powder 3g / L, ammonium sulfate 5g / L, anhydrous MgSO 4 0.25g / L, K 2 HPO 4 ·3H 2 O1g / L, KH 2 PO 4 1g / L, natural pH value, solvent is water. Use an inoculation needle to take a ring of bacteria from the slant medium and inoculate it into a 250ml Erlenmeyer flask containing 100ml of liquid medium, and culture it at 30°C and 180r / min for 24 hours to obtain a seed solution. Inoculate the seed solution with a 10% inoculum amount into a 250ml Erlenmeyer flask containing 100ml of liquid medium, culture it at 30°C and 180r / min f...

Embodiment 2

[0038] CGMCC No.2230 was cultivated according to the method in Example 1 to obtain bacterial cell fermentation broth. Mix 4 bottles of 100ml fermentation broth with a dry weight of 450mg bacteria with an equal volume of 2% sodium alginate solution to make a mixed solution, put the mixed solution into a syringe, and drop 3.5% CaCl 2 Form immobilized particles in the solution (1000ml), the diameter of the formed immobilized particles is 2mm, and solidify at 37°C for 30min, and the obtained immobilized particles are washed with sterile physiological saline to wash away excess calcium ions and uncaptured cells. The obtained 4 bottles of immobilized cell pellets continued to proliferate and culture in the fermentation medium for 0h, 24h, 48h and 72h respectively.

[0039] Add the 4 kinds of immobilized cell particles that have been proliferated and cultured into 300ml dibutyl phthalate containing 36.6mmol methyl benzoylformate, and carry out biotransformation under the conditions o...

Embodiment 3

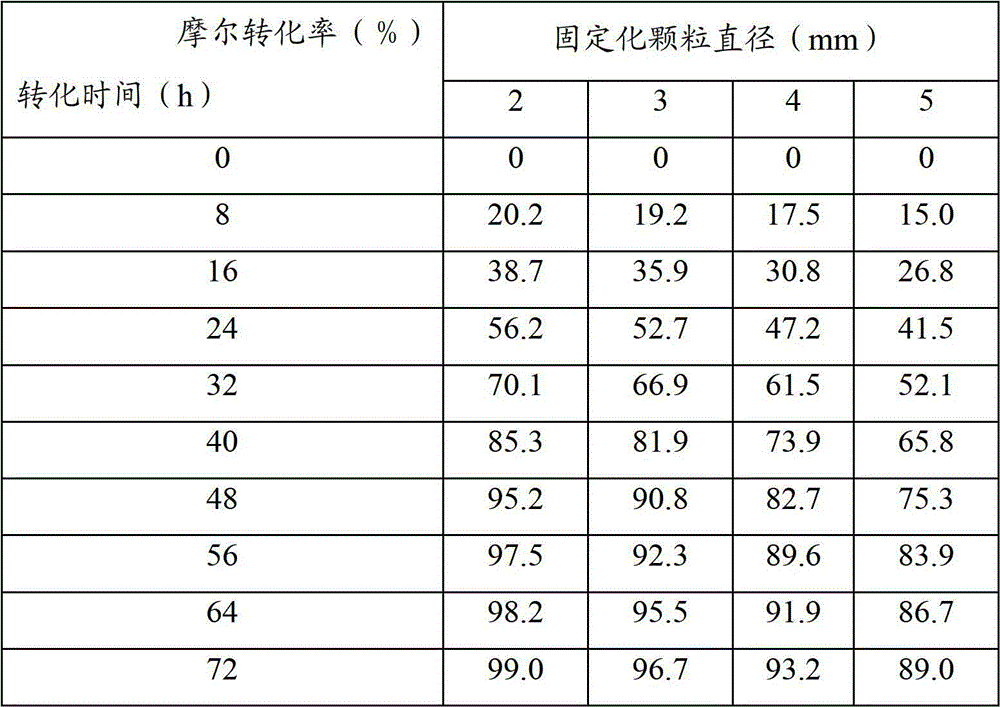

[0043] CGMCC No.2230 was cultivated according to the method in Example 1 to obtain bacterial cell fermentation broth. Mix 4 bottles of 100ml fermentation broth with a dry weight of 450mg and an equal volume of 2% sodium alginate solution to make a mixture, put the mixture into syringes with different needle sizes, and drop 3.5% CaCl 2 (1000ml) to form immobilized particles in the solution, the diameters of the formed immobilized particles were 2mm, 3mm, 4mm and 5mm, and solidified at 37°C for 30min, and the obtained immobilized particles were washed with sterile normal saline to remove excess calcium ions and uncaptured cells, and the obtained immobilized cell particles continued to proliferate and culture in the fermentation medium for 72 hours.

[0044] Add the 4 kinds of immobilized cell particles that have been proliferated and cultured into 300ml dibutyl phthalate containing 36.6mmol methyl benzoylformate, and carry out biotransformation under the conditions of 30°C and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com