Carbon nanometer tube modified resin/glass fiber composite reinforcement material and preparation method thereof

A carbon nanotube modification, glass fiber technology, applied in the field of structural engineering, can solve problems such as hindering application, low elastic modulus and shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

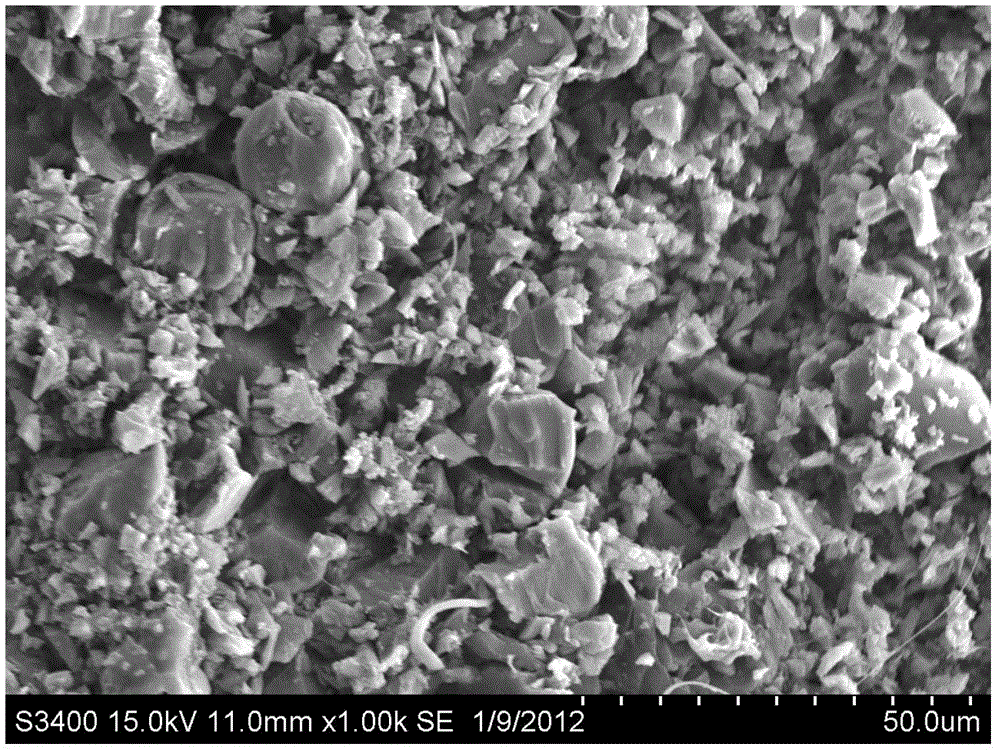

Image

Examples

Embodiment 1

[0016] Carbon nanotube modified resin / glass fiber composite reinforcement is made of 70% by weight continuous glass fiber (model A-Glass, purchased from Owens Corning OCV TM businesses) and 30% modified resin matrix material; the modified resin matrix material is carbon nanotube modified epoxy resin (for the modification process, refer to "Multi-walled carbon nanotube modified epoxy resin adhesive Experimental Research", Journal of Composite Materials, Issue 3, 2011).

[0017] The preparation method of the carbon nanotube modified resin / glass fiber composite reinforcement comprises the following steps: the continuous glass fiber first impregnates the carbon nanotube modified epoxy resin solution in the dipping device through the wire plate, and the carbon nanotube modified epoxy resin solution is mixed with the carbon nanotube modified The epoxy resin is glued, and then prepared into ribs by pultrusion process. Before curing, the glass fiber is unidirectionally wound on the s...

Embodiment 2

[0020] The carbon nanotube modified resin / glass fiber composite reinforcement is formed by gluing multiple strands of 80% by weight continuous glass fiber filaments (A-Glass) and 20% by weight of modified resin matrix materials; the modified resin matrix The material is urethane-modified vinyl ester resin modified by carbon nanotubes (the modification refers to the literature as in Example 1), and the preparation method is the same as in Example 1.

[0021] The control test results of modified GFRP bars and unmodified GFRP bars showed that the ultimate tensile strength increased by 12%, and the ultimate elongation increased by 8%. The modulus of elasticity increased by 20%, and the shear strength increased by 7%.

Embodiment 3

[0023] The difference from Example 1 is that the carbon nanotube modified resin / glass fiber composite reinforcement is formed by gluing 75% by weight of continuous glass fiber and 25% by weight of modified resin matrix material.

[0024] The control test results of modified GFRP bars and unmodified GFRP bars showed that the ultimate tensile strength increased by 13%, and the ultimate elongation increased by 9%. The modulus of elasticity increased by 30%, and the shear strength increased by 10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com