Method for preparing CuInS2 nanocrystalline and CuInS2/ZnS core-shell structure nanocrystalline

A nanocrystal and material technology, which is applied in the preparation of CuInS2/ZnS core-shell nanocrystals (quantum dots) and the preparation of CuInS2 nanocrystals (quantum dots), can solve the problems of inseparability, low fluorescence quantum yield of nanocrystals, problems such as poor repeatability, to achieve the effect of wide spectrum coverage, easy availability of raw materials and stable, improved quantum yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

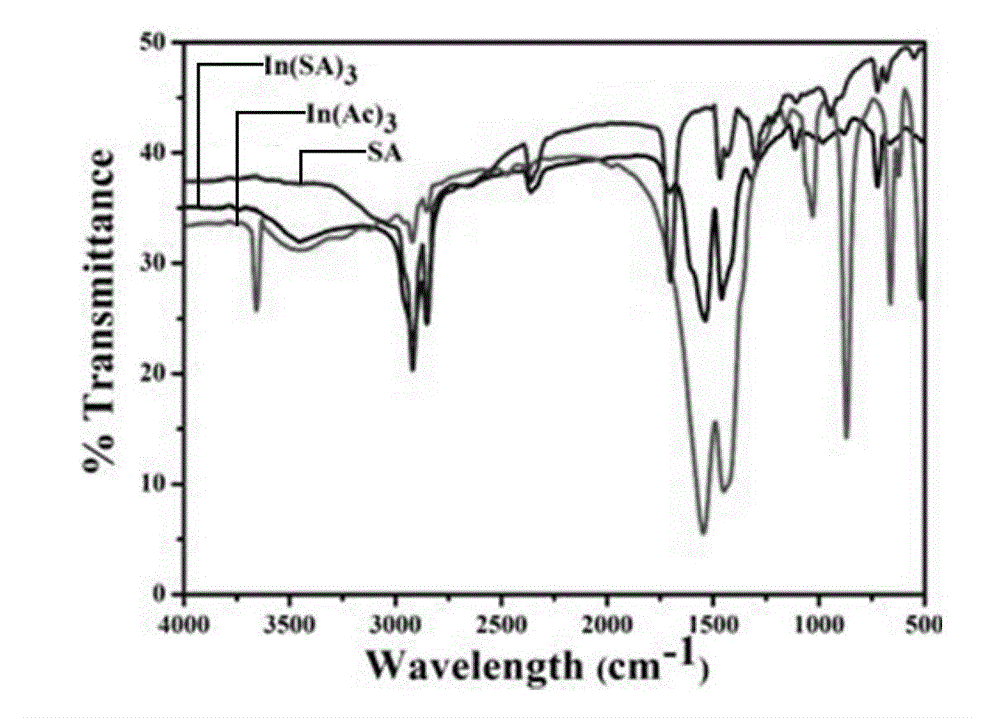

[0030] 1) Weigh 2.92g of In(Ac) 3 and the 95% stearic acid of 36g are put into there-necked bottle, under nitrogen atmosphere, at 140 o C was reacted for 5 hours, cooled to room temperature, then washed three times with acetone, after filtering and vacuum drying, the crude product of indium stearate was obtained;

[0031] 2) Put it and 24g of 95% stearic acid into a three-necked bottle, and the other reaction conditions are the same as step 1). After the reaction product is washed with acetone, filtered, and vacuum-dried, it is ground into indium stearate powder;

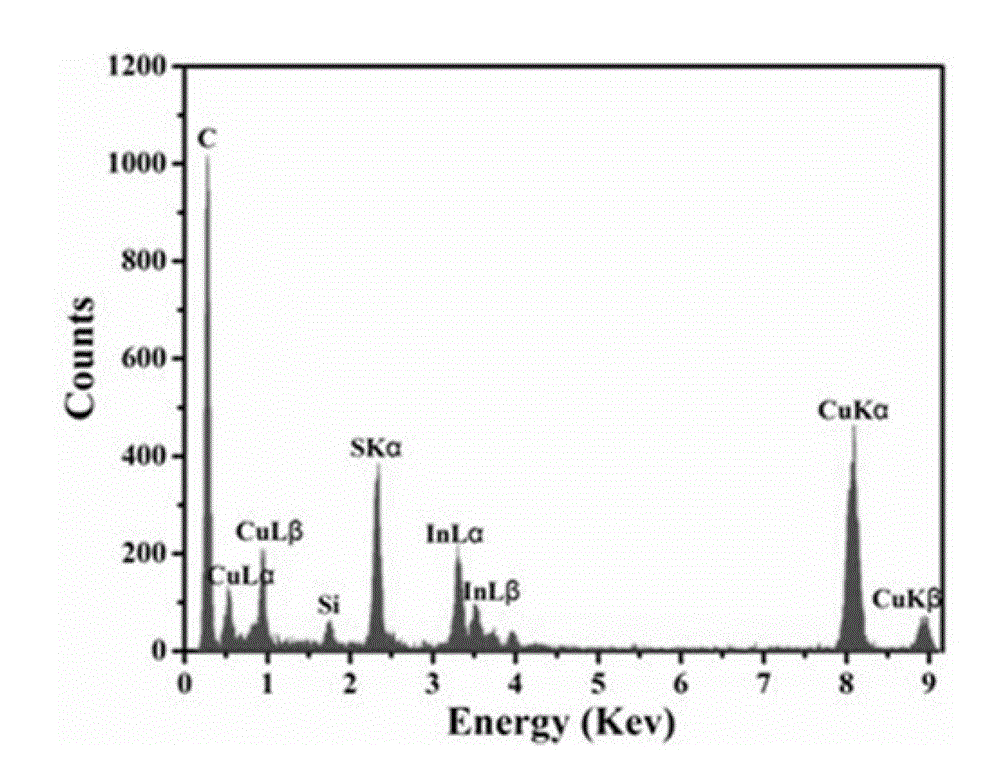

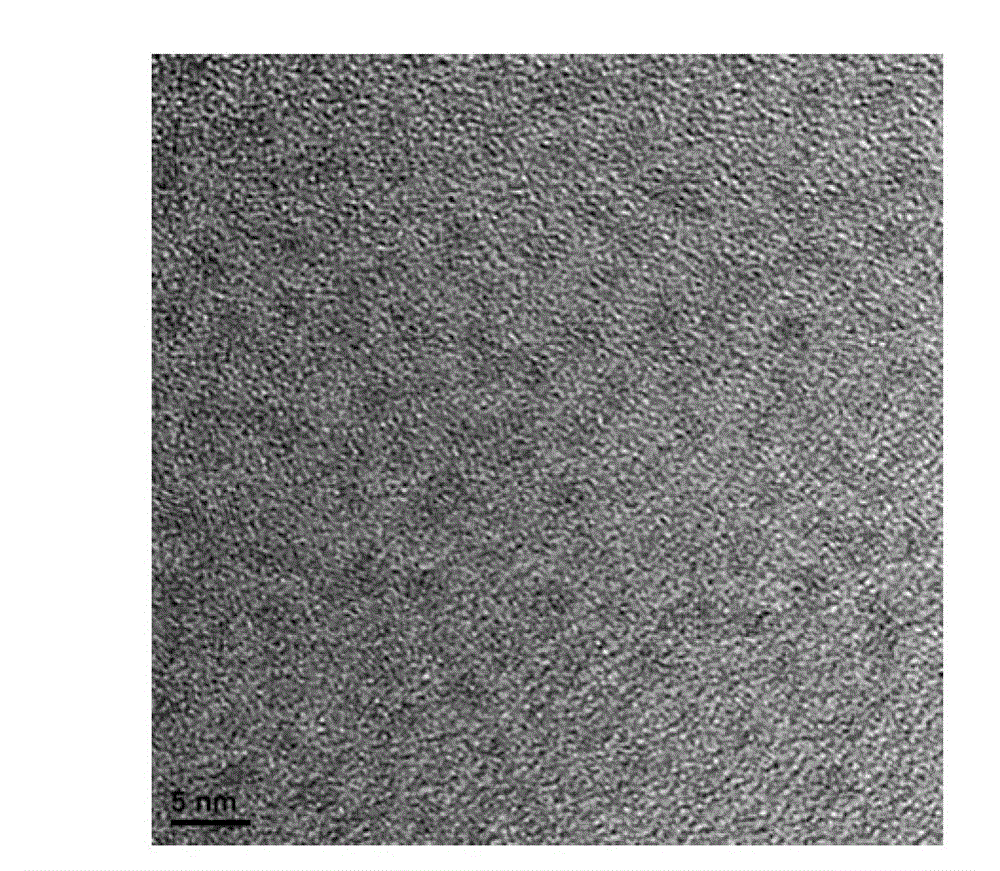

[0032] 3) Dissolve 0.0191g of CuI and 0.1g of indium stearate powder in a mixed solvent containing 210 μl of oleic acid, 1 ml of dodecanethiol and 10 ml of octadecene, and raise the temperature to 70 o C, hold for 45 minutes, then increase to 225 o C, react for 55 minutes (and take samples after reacting to 5, 10, 20, 30, 40, 50 minutes respectively), cool to room temperature, disperse it in 5ml of chloroform an...

Embodiment 2

[0035] 1) Weigh 2.92gIn(Ac) 3 and the 95% stearic acid of 36g are put into there-necked bottle, under nitrogen atmosphere, at 140 o C was reacted for 5 hours, cooled to room temperature, then washed three times with acetone, filtered to obtain indium stearate, and after vacuum drying, the crude product of indium stearate was obtained;

[0036] 2) Put it and 24g of 95% stearic acid into a three-necked bottle, and the other reaction conditions are the same as step 1). After the reaction product is washed with acetone, filtered, and vacuum-dried, it is ground into indium stearate powder;

[0037] 3) 0.0191g of CuI and 0.1g of 95% indium stearate were dissolved in a mixed solvent containing 210 μl of oleic acid, 1ml of dodecyl mercaptan and 10ml of octadecene, and under a nitrogen atmosphere, the temperature was raised to 70 o C, hold for 45 minutes, then increase to 225 o C, react for 30 minutes;

[0038] 4) Dissolve 0.316g of zinc stearate in a mixed solvent of 2ml of octad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com