Bagging packaging method for poly vinyl chloride (PVC) pipe

A packaging method, PVC pipe technology, applied in packaging and other directions, can solve problems such as pollution, low efficiency, and waste of the environment, and achieve the effects of saving labor costs, improving efficiency, and maintaining long-term effective working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

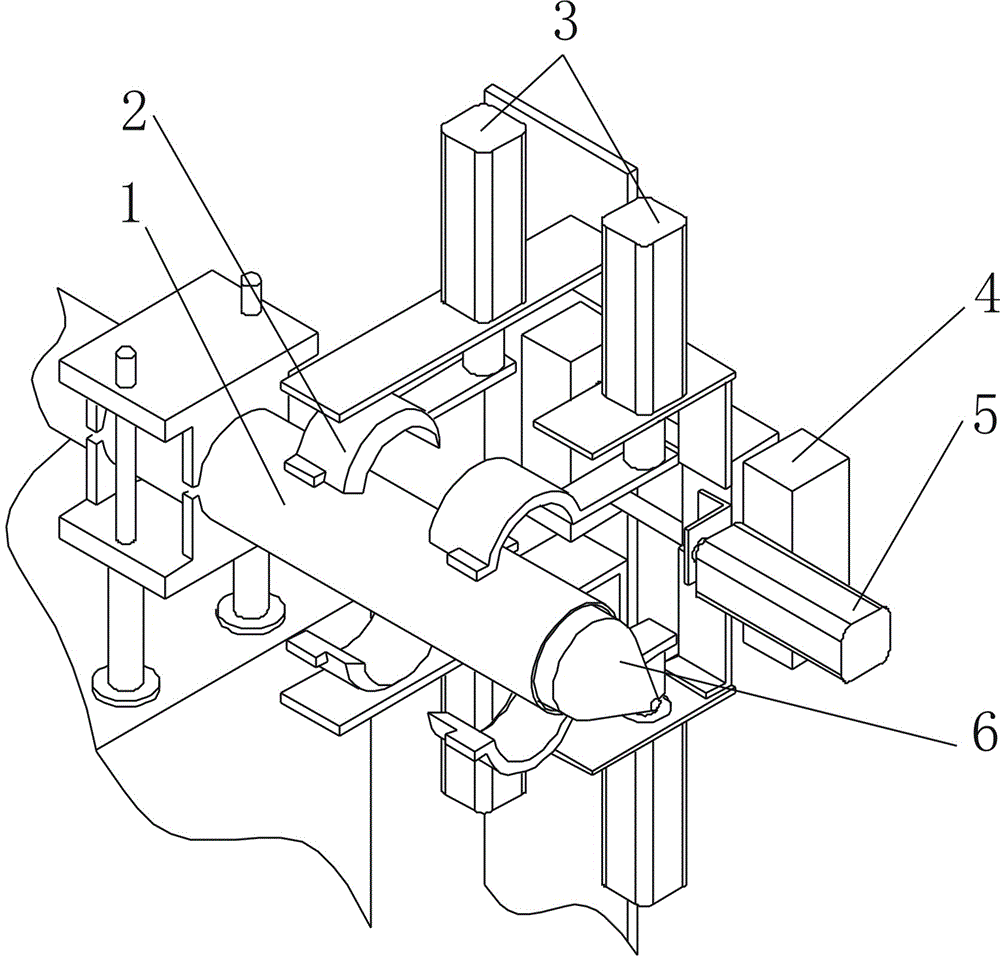

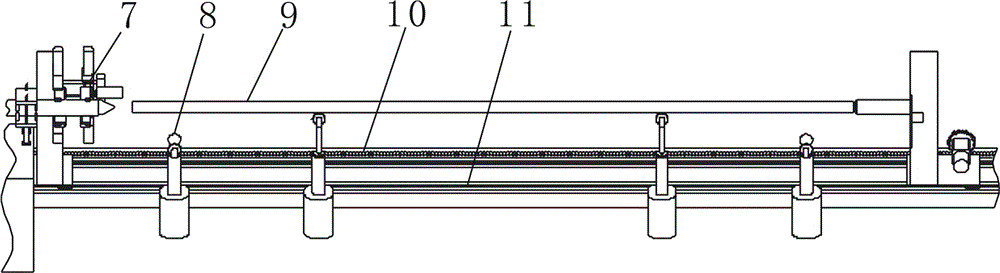

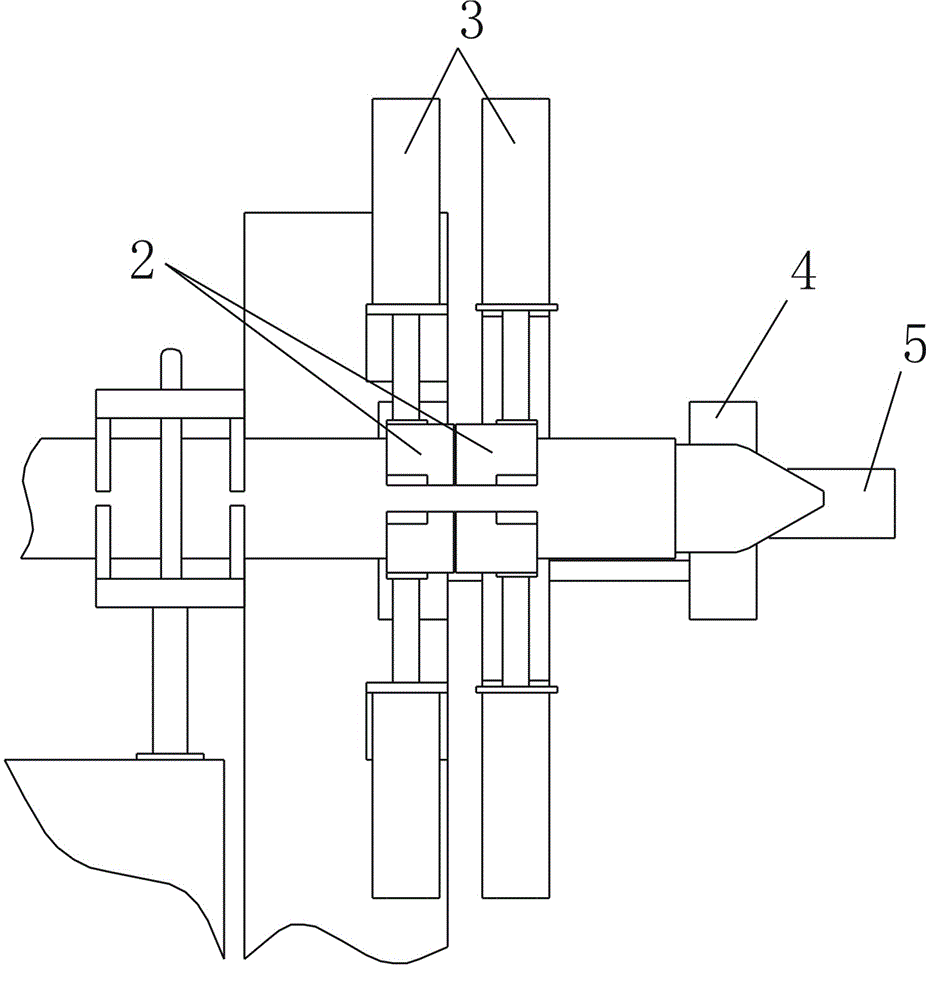

[0031] The bag grabbing device adopted in the bagging and packaging method of PVC pipes provided by the invention is as follows: figure 1 and 2 As shown, the bag grabbing device 7 is arranged on the guide rail and can move along the guide rail. The bag grabbing device 7 is fixedly installed on the horizontally movable flat plate on the guide rail 11. A motor is installed on the flat plate. When the motor rotates, the gear and the rack are engaged. , so that the flat panel can move forward and backward along the guide rail 11.

[0032] The bag grabbing device 7 mainly includes two groups of clamps 2 that are vertical and horizontal to the guide rails and can be clamped radially. A layer of rubber, on the one hand, avoids the impact on the type support, on the other hand, it can increase the friction between the clamp and the packaging bag; Axially adjacent clamping surfaces form a ramp fit. Each set of clamps 2 is provided with a pair of first cylinders 3 facing up and down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com