Braking device of heavy-duty mining dump truck

A mining dump truck and braking device technology, applied in the direction of hydraulic brake transmission, brakes, etc., can solve the problems of small braking torque, unsuitable for large-tonnage dump trucks, and complicated pipeline connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

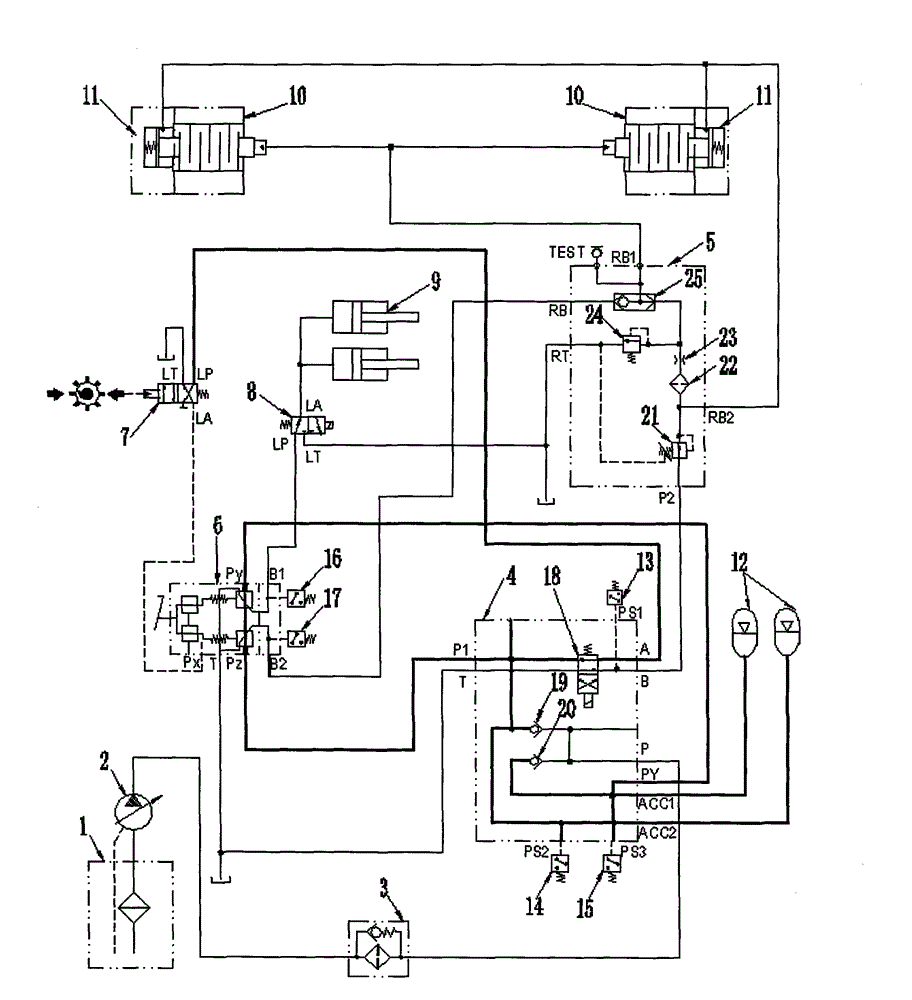

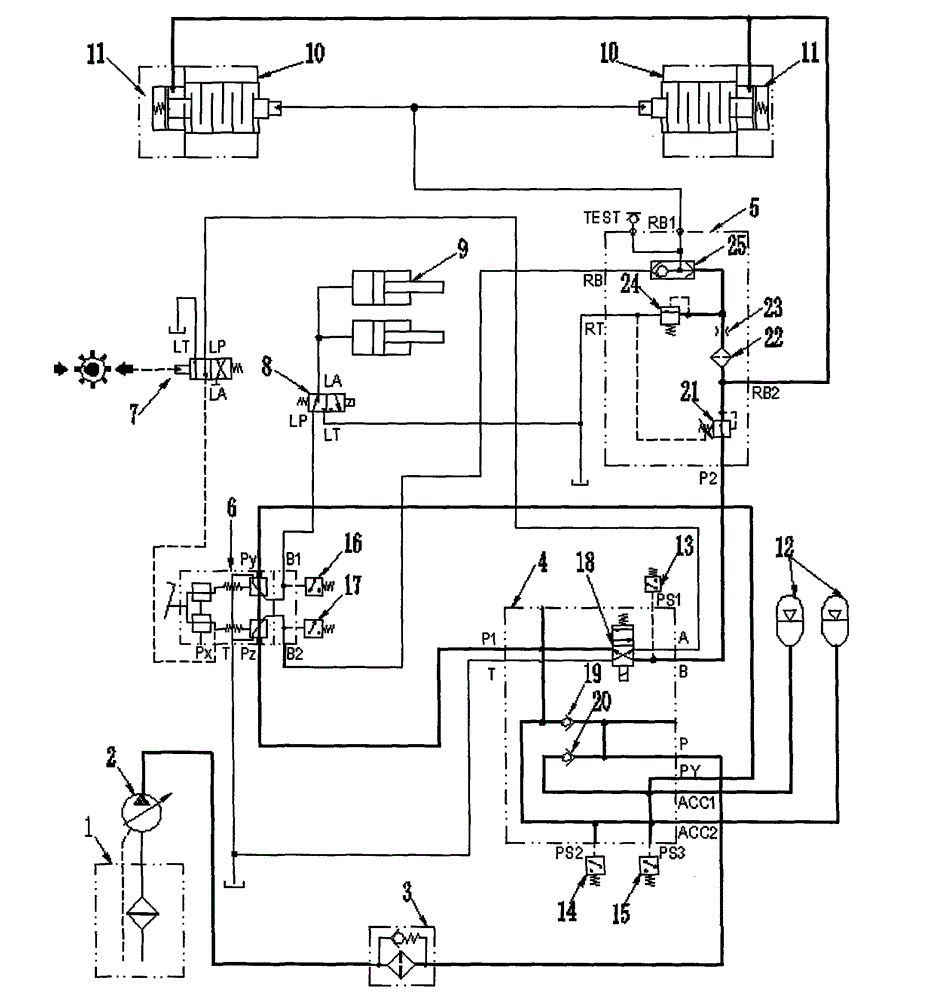

[0018] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

[0019] refer to Figure 1 to Figure 4 As shown, the present invention fuel tank 1, brake pump 2, filter 3, brake multi-way valve 4, parking brake valve 5, brake pedal valve 6, direction control valve 7, loading brake valve 8, front wheel Brake 9, rear wheel brake 10, parking brake 11, accumulator 12, parking brake pressure switch 13, rear brake accumulator pressure switch 14, front brake accumulator pressure switch 15, rear brake pressure The switch 16, the front brake pressure switch 17, the oil suction port of the brake pump 2 is connected to the oil tank 1, and the oil outlet is connected to the brake multi-way valve 4 through the filter 2; Valve 5 and brake pedal valve 6 are connected, and the brake pedal valve 6 is connected with the front brake 9 and the parking brake valve 5 respectively, and the parking brake valve 5 is connected with the rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com