Combined inhibitor used for flotation of low-grade nickel ore with high content of sliding magnesium rock

A low-grade nickel ore, combined inhibitor technology, applied in flotation, solid separation and other directions, can solve the problems of complex process, low flotation recovery rate, affecting nickel flotation index and metal recovery rate, etc., and achieve high recovery rate , the effect of effective flotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] According to the combination inhibitor prepared in the following ratio, the dosage of each component per ton of raw ore is: sodium hexametaphosphate: 500g / t ore, sodium carboxymethylcellulose: 700g / t ore, sodium carbonate: 300g / t ore, sulfuric acid Amine: 360g / t ore, copper sulfate: 300g / t ore, xanthate: 380g / t ore, MIBC: 150g / t ore; first prepare sodium hexametaphosphate and sodium carboxymethylcellulose into an aqueous solution, in which hexametaphosphate The mass concentration of sodium phosphate is 5%.

[0044] First, sodium carboxymethyl cellulose and sodium hexametaphosphate need to be formulated into an aqueous solution, which is added to the pulp in proportion and stirred for 5 minutes, then sodium carbonate, ammonium sulfate, and copper sulfate are added in turn in proportion to stir for 5 minutes, and then amyl Xanthate and MIBC are stirred for 3 to 5 minutes and then enter the flotation machine for flotation.

[0045] Each component is added to the pulp and ...

Embodiment 2

[0047] Flotation process is identical with embodiment 1, and its difference is the difference of the addition amount of combined inhibitor, and after each component is formulated into working liquid, then joins in the ore pulp and carries out flotation after fully stirring:

[0048]The amount of each component per ton of raw ore is: sodium carboxymethyl cellulose: 780g / t ore, sodium hexametaphosphate: 600g / t ore, sodium carbonate: 350g / t ore, ammonium sulfate: 300g / t ore, copper sulfate : 200g / t ore, xanthate: 280g / t ore, MIBC: 100g / t ore; the mass concentration of sodium hexametaphosphate in the working fluid is 4.5%.

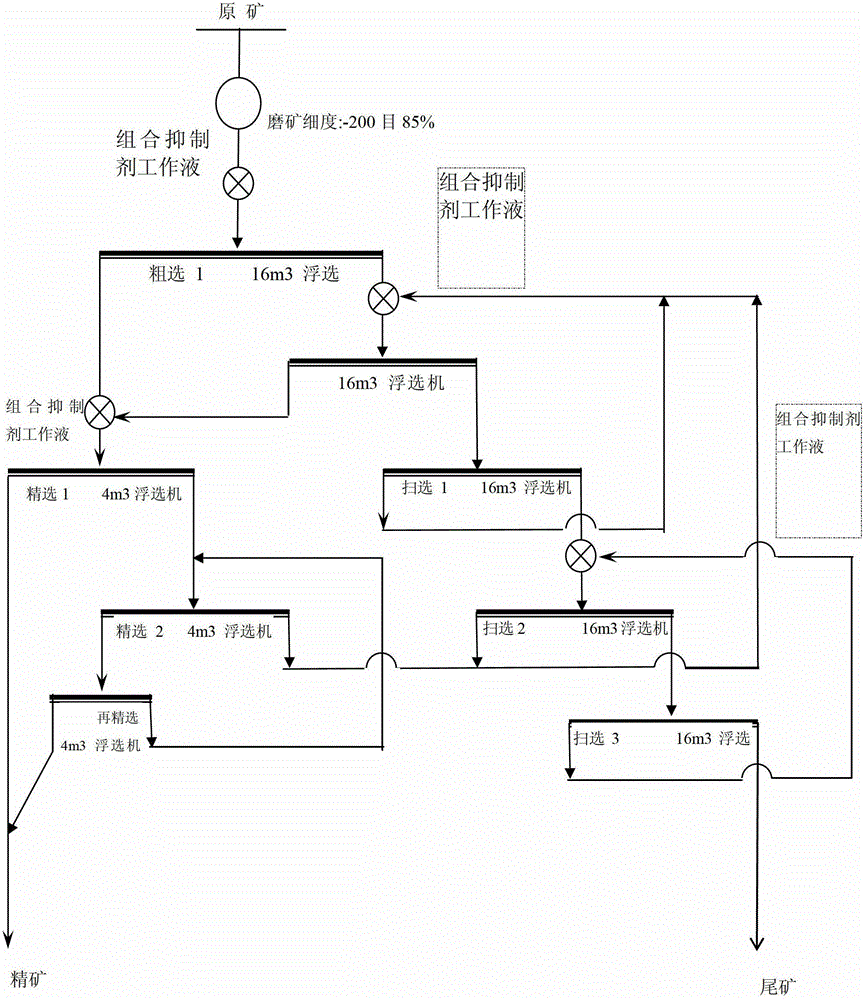

[0049] Each component is added to the pulp and enters the flotation machine, according to figure 1 The flotation process shown in the figure; flotation of nickel ore with a content of 49.64% stalbeite and a nickel grade of 0.43% in the raw ore, resulting in a concentrate with a nickel grade of 5.1% and a nickel recovery rate of 76.2%.

Embodiment 3

[0051] Flotation process is identical with embodiment 1, and its difference is the difference of the addition of combination depressant:

[0052] The dosage of each component per ton of raw ore is: sodium carboxymethyl cellulose: 800g / t ore, sodium hexametaphosphate: 650g / t ore, sodium carbonate 400g / t ore, ammonium sulfate: 380g / t ore, copper sulfate: 260g / t ore, xanthate: 300g / t ore, MIBC: 120g / t ore.

[0053] Each component is added to the pulp and enters the flotation machine, according to figure 1 The flotation process shown in the figure adopts the flotation process of secondary roughing, secondary sweeping, and secondary beneficiation; flotation is carried out on the nickel ore with a content of 49.64% stalciteite and a nickel grade of 0.53% in the original ore, and the result is obtained The concentrate nickel grade was 5.6%, and the nickel recovery rate was 78.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com