Bopp with homogeneous film morphology

A technology of polypropylene film and thin layer, applied in the direction of organic insulators, plastic/resin/wax insulators, electrical components, etc., can solve the problems that dominate the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

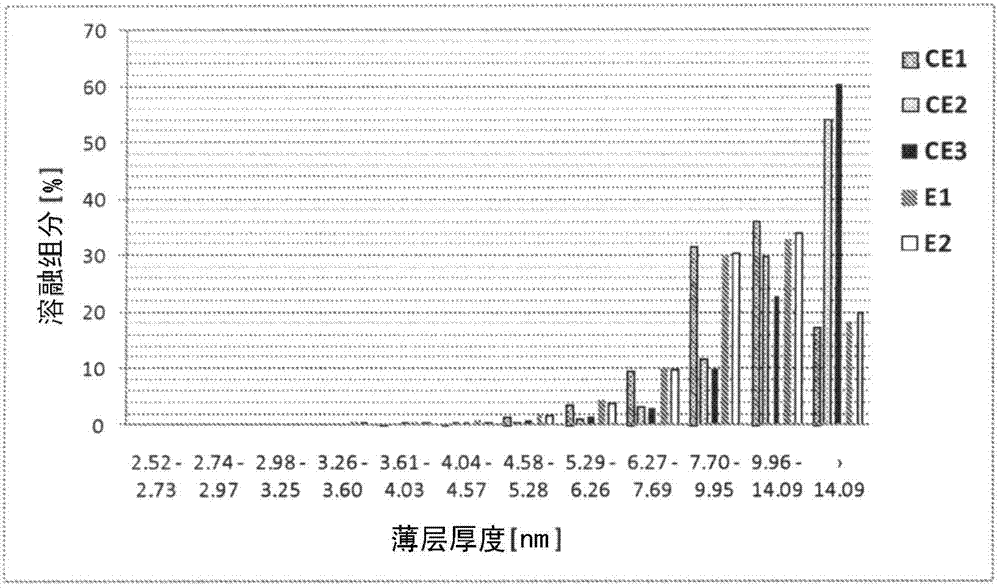

Image

Examples

preparation example Construction

[0070] The preparation of the polypropylene of the present invention is described in more detail below.

[0071] The polypropylene of the present invention is obtained in particular by a novel catalyst system according to ASTM D 3663 (N 2 ) measured for surface areas below 20m 2 / g and comprising a catalyst represented by a transition metal compound of formula (I):

[0072] (Cp) 2 wxya 2 (I)

[0073] in:

[0074] X is independently a monovalent anionic ligand, such as a σ ligand,

[0075]Cp is an organic ligand selected from the group consisting of unsubstituted cyclopentadienyl, unsubstituted indenyl, unsubstituted tetrahydroindenyl, unsubstituted fluorenyl, substituted cyclopentadienyl , substituted indenyl, substituted tetrahydroindenyl, and substituted fluorenyl,

[0076] With the proviso that both Cp ligands are selected from the group mentioned above and that the two Cp ligands are chemically identical, i.e. identical,

[0077] R is a bridging group connecti...

Embodiment

[0165] A. Determination method

[0166] Unless otherwise stated, the following definitions of terms and determination methods are applicable to the above description and the following examples of the present invention. Quantification of microstructure by NMR spectroscopy

[0167] Quantitative nuclear magnetic resonance (NMR) spectroscopy was used to quantify the isotacticity, regio-regularity, and comonomer content of the polymers.

[0168] use for 1 H and 13 C Bruker Advance III 400NMR spectrometers operating at 400.15MHz and 100.62MHz respectively to record the quantitative 13 C{ 1 H} NMR spectrum. At 125°C, with nitrogen for all cavities, by using 13 C Optimal 10mm Extended Temperature Probe ( 13 C optimized 10mm extended temperature probehead) to record all spectra.

[0169] For polypropylene homopolymers, dissolve approximately 200 mg of material in 1,2-tetrachloroethane-d 2 (TCE-d 2 )middle. To ensure a homogeneous solution, after initial sample preparation in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface area | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com