Method for determination of inorganic element in fuel gas

An inorganic element and gas technology, which is used in measuring devices, material analysis by electromagnetic means, instruments, etc., can solve the problems of low detection sensitivity of non-metallic elements, cumbersome operation, hindering application and development, etc., to meet the requirements of detection and research. needs, low operating costs, and the effect of easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1. Sample collection:

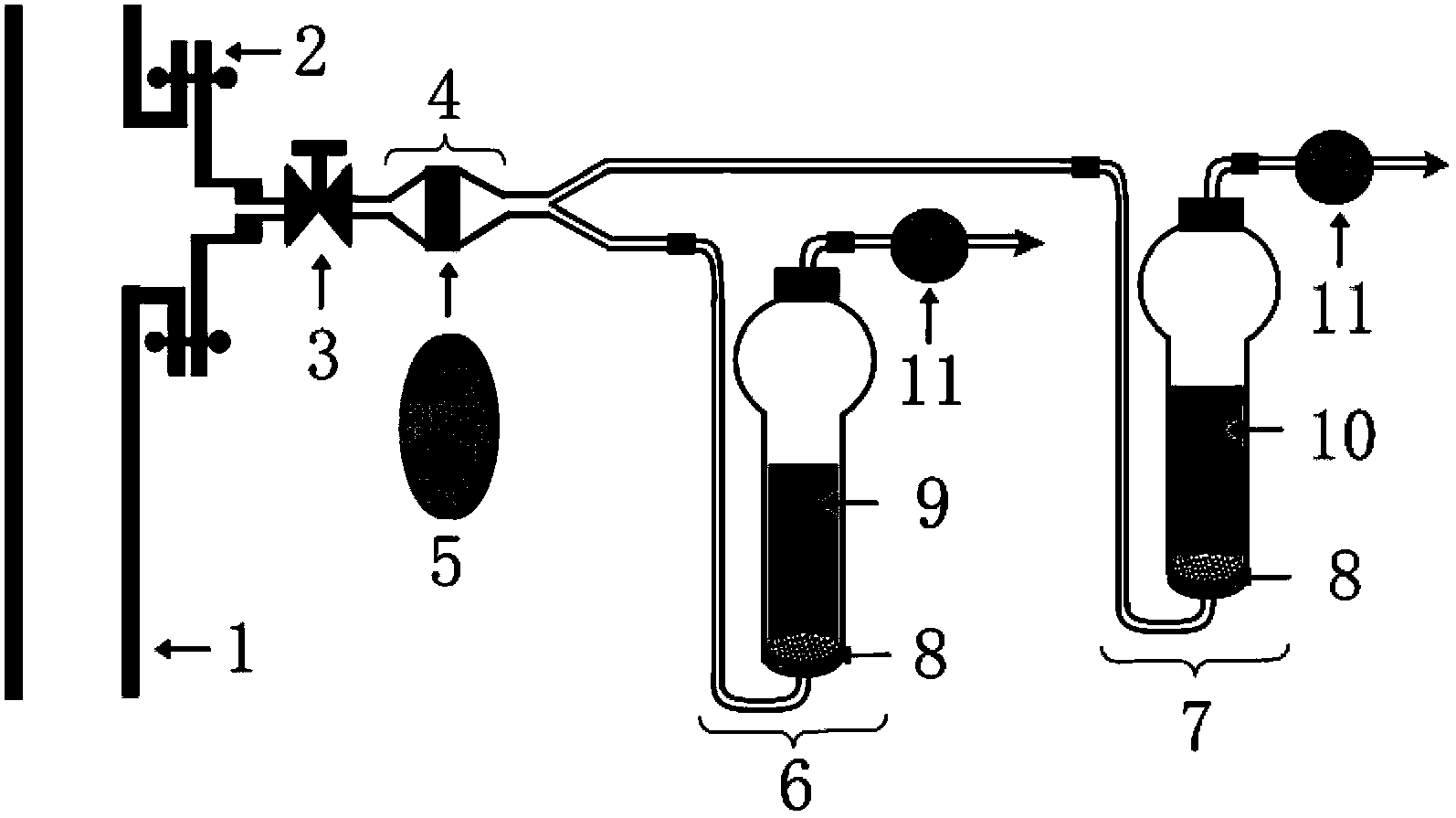

[0048] The gas is collected by using a double-flow path gas-liquid absorption device, and the diameter of the filter membrane is 45mm. At a flow rate of 400mL / min, collect for 90min. The cation absorption bottle contains 6mL of 50mmol / L boric acid solution (used to absorb soluble cations in gas). The anion absorption bottle contains 6mL of 50mmol / L sodium hydroxide solution (used to absorb soluble anions in gas).

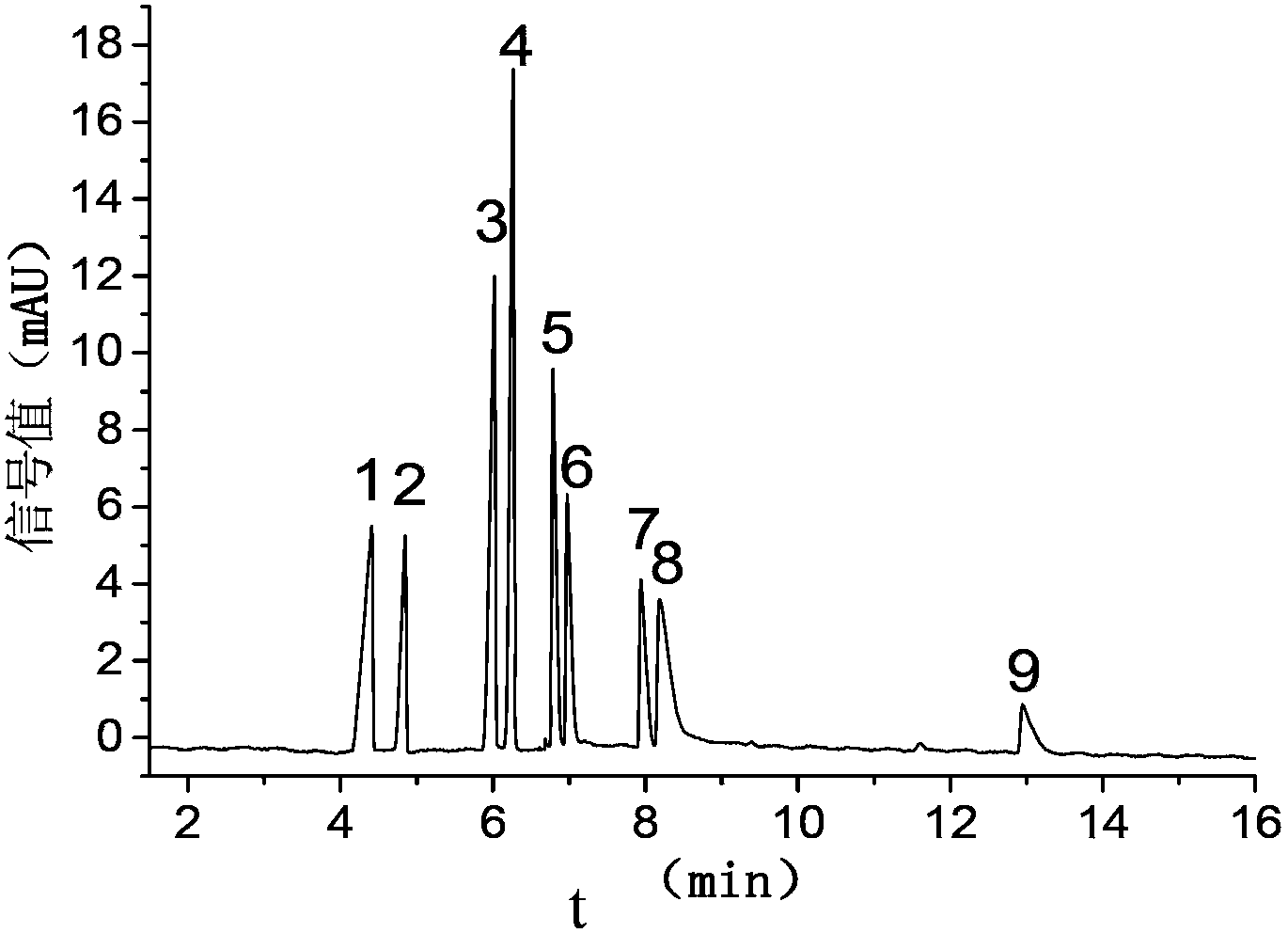

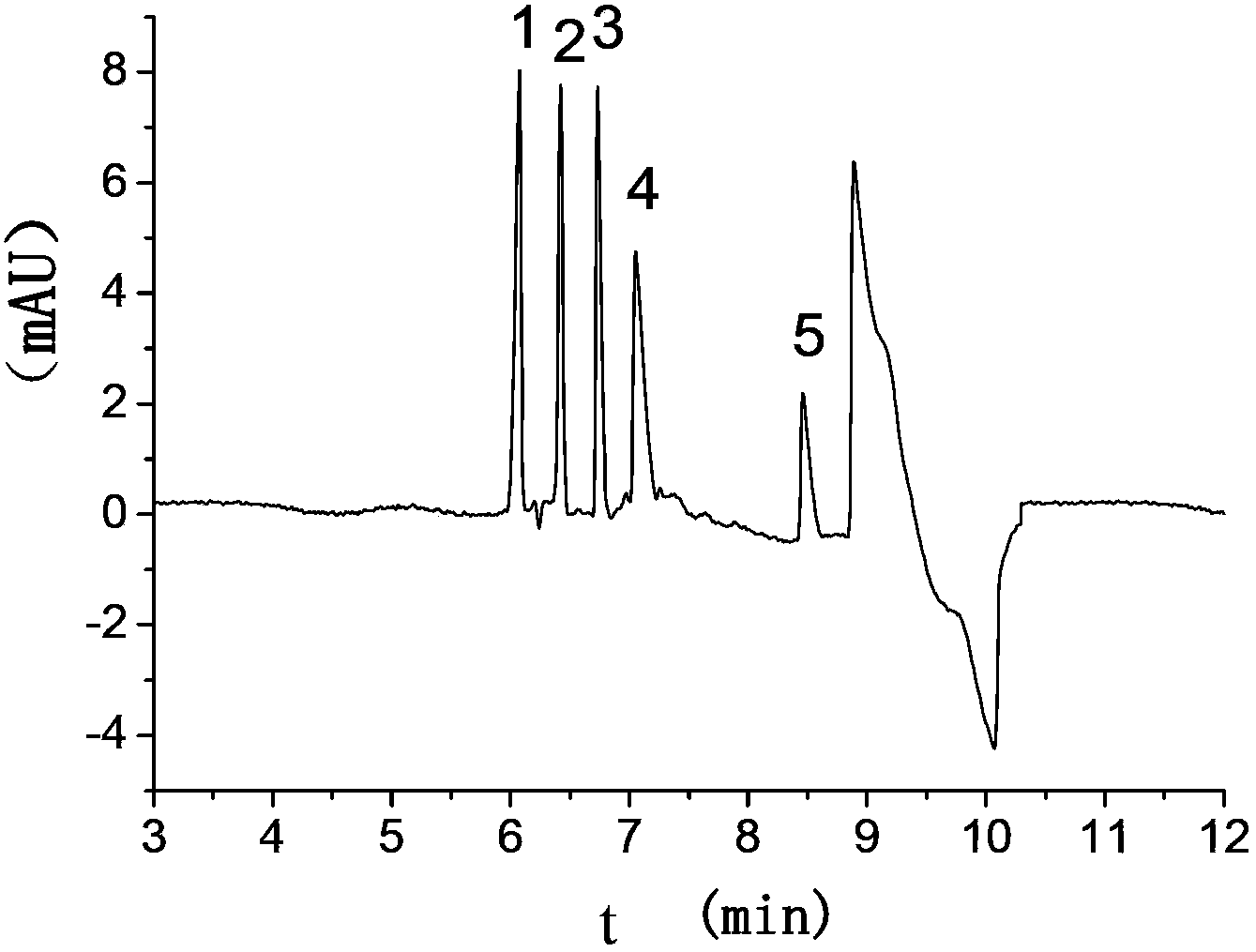

[0049] 2. Sample treatment: Divide the collected sample filter membrane into two halves, cut one half into pieces, add 6 mL of analytically pure nitric acid, and put it into a microwave instrument for microwave-assisted digestion. Pour the digested solution into a polytetrafluoroethylene bottle, add the sample containing 50mmol / L boric acid absorption solution, mix well and make up to volume (12ml), and filter it through a 0.45μm membrane for inorganic cation analysis; cut the other half After crushing, add 6mL double-distilled wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com