Flexible support frame for small high-stability multifunctional optical reflector

An optical mirror, high stability technology, applied in the field of space optics, can solve problems such as unfavorable large-scale, large-scale use, limited use and size of flexible structures, complex flexible structures, etc., to achieve convenient design and processing. and savings, the design variables are simple and controllable, and the strength is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

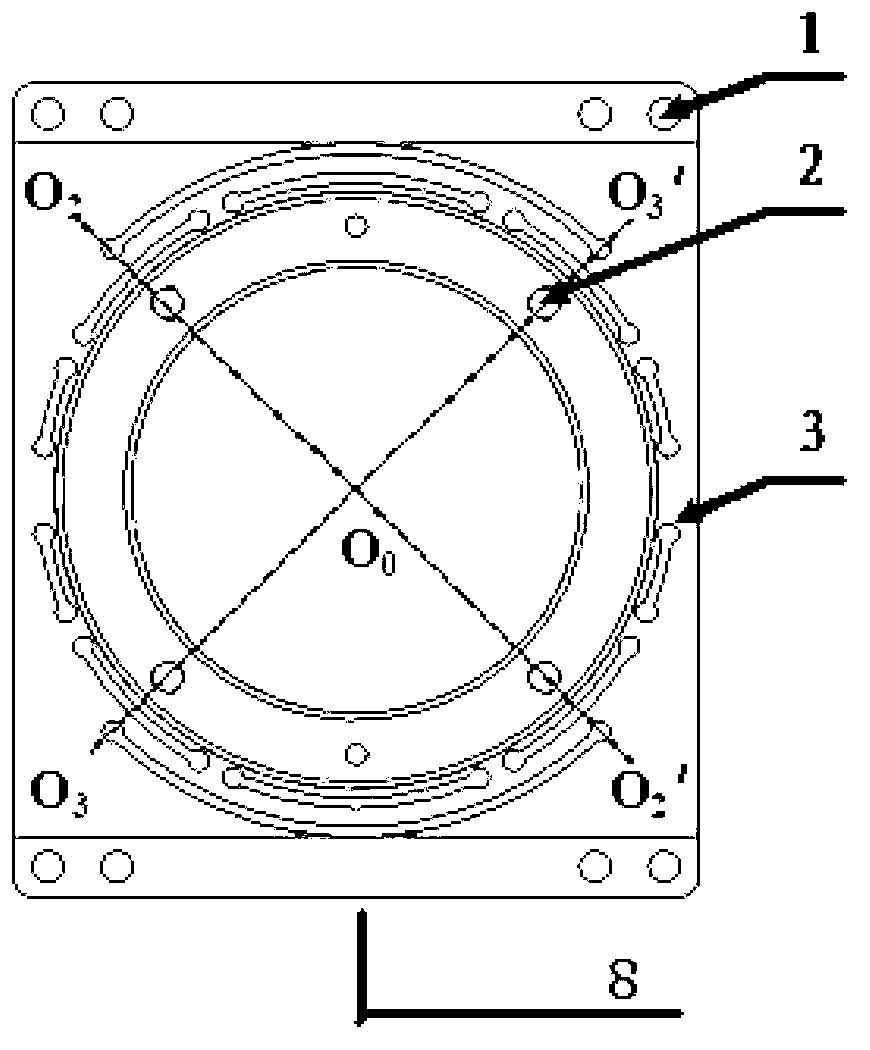

[0017] like Figure 1-2 As shown, the flexible support frame of the small-scale high-stable multifunctional optical mirror includes: the flexible support frame 8, the flexible support frame 8 is a rectangular structure containing a hollow circle, and the mechanical connection platform of the rectangular boss structure with the same width is processed on both sides 5. Two mechanical interfaces 1 are processed at both ends of the mechanical connection platform 5, and the optical-mechanical connection platform 7 is processed along the hollow circle with a ring-shaped convex structure. The bottom surface of the optical-mechanical connection platform 7 is processed with a concave structure, and the mechanical connection platform 5 and the optical-mechanical Process concave structure unloading substrate 6 between connecting platforms 7, unloading slit 3 for processing circular topological structure on unloading substrate 6, topological structure axis O 1 o 1 'Coaxial with the axis ...

specific Embodiment approach 2

[0021] The flexible support frame 8 and the optical reflector 9 adopt a split structure, which increases the manufacturability and versatility. When the optical reflector is made of metal or SiC, the connection between the flexible support frame and the optical reflector 9 is through an optical-mechanical interface 2. The pin hole 4 is connected to the optical-mechanical connection platform 7. The pin hole 4 ensures the connection positioning accuracy and repeated installation positioning accuracy of the optical-mechanical connection platform 7 and the optical mirror 9, and unloads the substrate 6 to the mechanical connection platform 5 and the optical-mechanical connection platform 7. The generated assembly stress and thermal stress are evenly distributed to prevent stress concentration, and the unloading slit 3 on the unloading substrate 6 is divided into two parts, the inner layer and the outer layer, the inner layer is connected to the optical-mechanical connection platform ...

specific Embodiment approach 3

[0023] The material used for the flexible support frame 8 can be selected from Invar material that matches the thermal expansion coefficient of the material used in the optical reflector 9, so as to minimize the influence of thermal mismatch on the mirror surface shape of the optical reflector, or choose a tensile Titanium alloy material with higher strength and better processing performance.

[0024] The flexible support frame uses Invar from Beijing Yuhang Yincai Technology Development Co., Ltd. or titanium alloy (TC4) from Shenyang Institute of Metal Research, Chinese Academy of Sciences as the structural material, and undergoes multiple vacuum aging treatments during the specific processing process. The unloading slits 3 of the inner and outer layers of the flexible support frame are all processed by wire-cutting in a slow-moving manner, and the surface quality of the parts is strictly controlled. Its surface finish is 0.6-0.9, without machining tool marks, and the corners...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com