Selective absorbing dry method paper filter material for cigarette filter tip rod and preparation method thereof

A cigarette filter and selective adsorption technology, which is applied in papermaking, paper coating, textiles and papermaking, etc., can solve the problems of reducing the tar content of aroma-causing substances, not reducing aroma-causing components, and reducing harmful components, so as to improve the quality of smoking , Improve safety and reduce hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

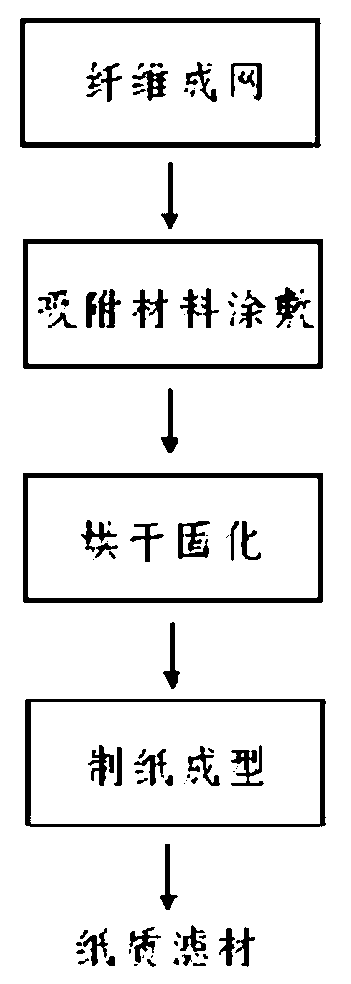

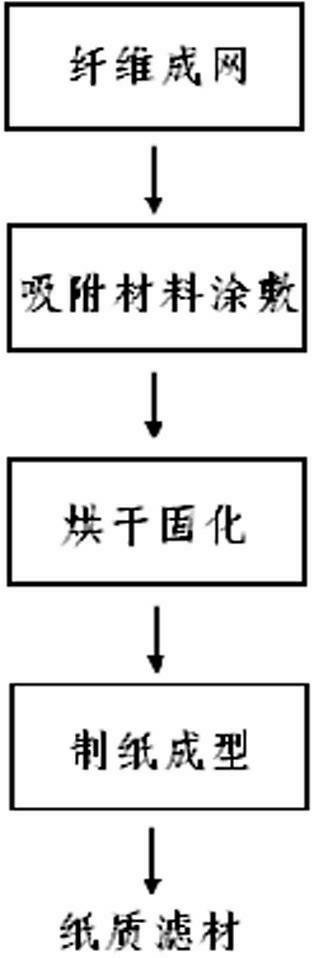

Method used

Image

Examples

Embodiment 1

[0032] Select 2.5kg of sepiolite and 5kg of diatomite with a particle size distribution of 140-200 meshes as the adsorption material, mix 90kg of wood pulp fiber containing 80% and 20% of viscose fiber with 10kg of hot-melt fiber by air-laid method Form a fiber web and pre-press; evenly spray and evenly distribute the adsorbent material in the laminated fiber web layer, roll forming, and then heat at 110 ° C, dry, bond and reinforce, and prepare a dry-laid paper filter material. After testing, the physical indexes of the obtained dry-laid paper all meet the requirements of the filter rod forming machine. The filter rod is made by the filter rod forming machine. After testing, the physical properties of the filter rod meet the requirements of the industry, and the suction resistance range is stable. Applying the filter stick to cigarettes makes the cigarette aroma clearer and softer, reduces tar by 22%, reduces nicotine by 15%, and greatly reduces solid particulate matter a...

Embodiment 2

[0034] Choose attapulgite, pomelo peel particles, and loess particles with a particle size distribution of 60-100 mesh as adsorption materials. 80kg of bamboo pulp fiber, 15kg of zein fiber and 5kg of hot-melt fiber are air-laid to form a fiber web, which is pre-pressed; the adsorbent material is evenly sprayed and distributed in the laminated fiber web layer, rolled and formed, and then Heated at 120°C, dried, bonded and reinforced, and prepared into a dry-laid paper filter material. After testing, the physical indexes of the obtained dry-laid paper all meet the requirements of the filter rod forming machine. The filter rod is made by the filter rod forming machine. After testing, the physical properties of the filter rod meet the requirements of the industry, and the suction resistance range is stable. Applying the filter rod to cigarettes makes the cigarette aroma more elegant and significantly improves the taste stimulation, reduces tar by 47.2% year-on-year, reduces ...

Embodiment 3

[0036] Select 2.8kg of medical stone, 1.2kg of molecular sieve and 1.5kg of ion exchange resin with a particle size distribution of 650-900 mesh as the adsorption materials. 90kg of wood pulp fibers are air-laid to form a fiber web, and rolled; the adsorption material is evenly mixed in 10 kg of polyvinyl acetate emulsion binder, and applied to the fiber web, and then rolled; Methods Glue was applied to the front and back sides of the fiber web, rolled into shape, and finally dried in a drying cylinder at 130°C to prepare a dry-laid paper filter material. After testing, the physical indexes of the obtained dry-laid paper all meet the requirements of the filter rod forming machine. The filter rod is made by the filter rod forming machine. After testing, the physical properties of the filter rod meet the requirements of the industry, and the suction resistance range is stable. Applying the filter rod to cigarettes makes cigarettes more transparent and comfortable, reduces t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com