Process for producing propionate

A propionate and process technology, which is applied in the production process field of microbial fermentation to produce propionate, can solve the problem of high total cost, and achieve the effects of saving production cost, low price and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

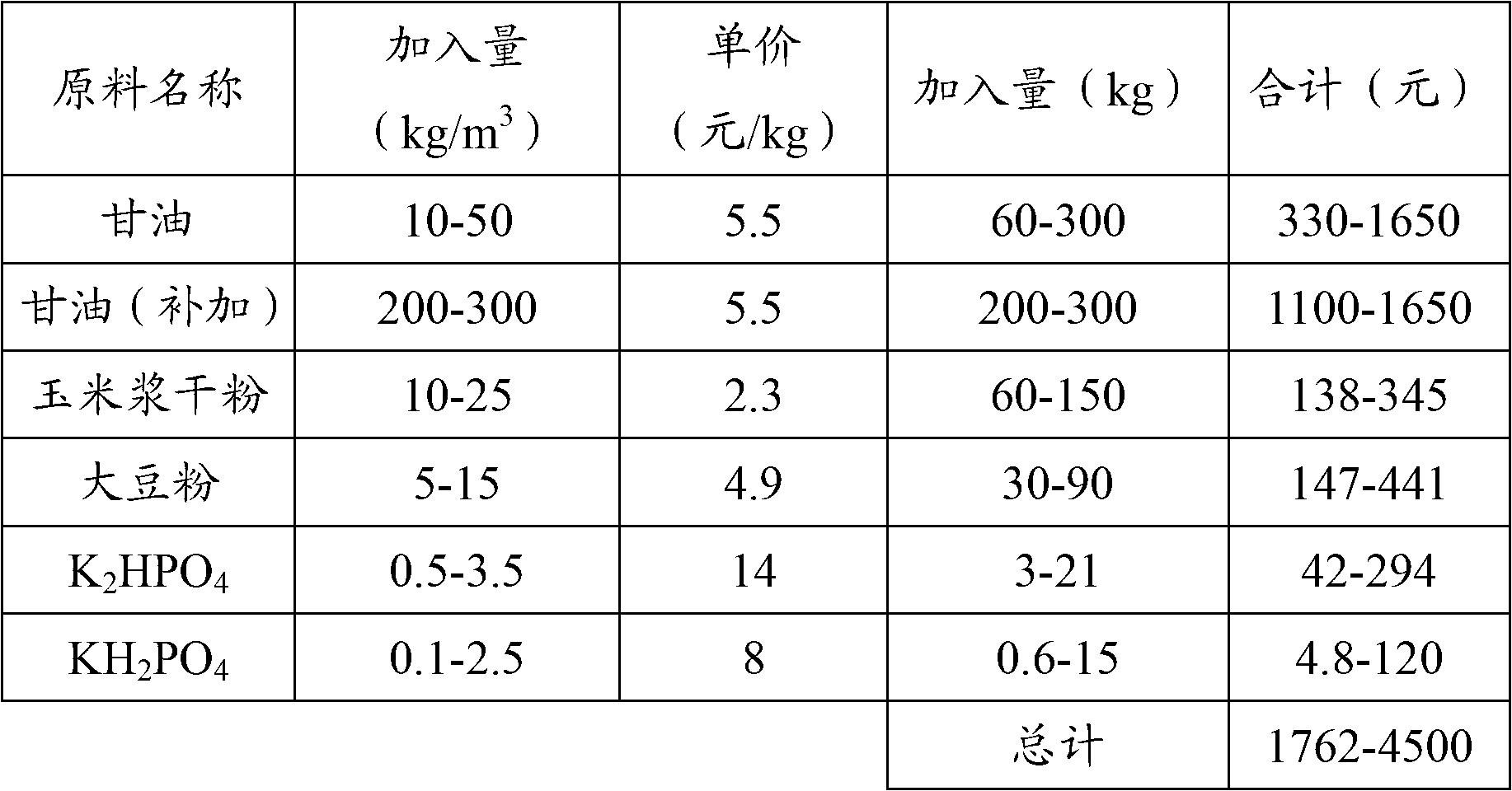

Examples

Embodiment 1

[0023] Embodiment 1 Fermentation process of the present invention produces calcium propionate

[0024] Strains: Propionibacterium acidipropionici (CGMCC1.2232);

[0025] Anaerobic bottle seed medium formula: yeast powder 10g / L, trypticase soybean broth 10g / L, K 2 HPO 4 2g / L, KH 2 PO 4 1g / L;

[0026] Seed pot medium formula (weight and volume percentage): 6% glycerin, 1% yeast extract, 0.5% tryptone, 0.3% dipotassium hydrogen phosphate, 0.3% potassium dihydrogen phosphate, and the balance is water;

[0027] Fermentation medium formula: corn steep liquor dry powder 10g / L, soybean powder 5g / L, K 2 HPO 4 0.5g / L, KH 2 PO 4 0.1g / L, glycerin 10g / L. Among them, corn steep liquor dry powder was purchased from Shandong Yuncheng Kangyuan Biotechnology Co., Ltd., soybean powder was purchased from Anyang Mantianxue Food Engineering Co., Ltd., and the trade name was deodorized sterilized soybean protein powder.

[0028] Inoculate the Propionibacterium acidogens preserved in conv...

Embodiment 2

[0032] Example 2 Existing fermentation process produces calcium propionate

[0033] Use the fermentation medium of existing technology (formulation is: yeast powder 5g / L, peptone 5g / L, K 2 HPO 4 0.5g / L, KH 2 PO 4 0.1g / L, glycerol 10g / L), calcium propionate was produced under the same conditions as those used in Example 1. The content of propionic acid is measured by high performance liquid chromatography. When the content of propionic acid is 31.1g / L, the pH value does not change any more, the content of propionic acid no longer increases, and the fermentation stops. The time used for fermentation is 239h, and the final volume of fermented liquid is 7.44m 3 .

[0034] Filter the obtained fermented liquid through a filter press, take the filtrate, send it to a spray tower for spray drying, and obtain 309.6 kg of calcium propionate after drying.

[0035] Obtainable by the fermentation effect of embodiment 1, embodiment 2, technique of the present invention has received bet...

Embodiment 3

[0036] Embodiment 3 Fermentation process of the present invention produces calcium propionate

[0037] Strains: Propionibacterium acidipropionici (CGMCC1.2232);

[0038] Anaerobic bottle seed medium formula: yeast powder 10g / L, trypticase soybean broth 10g / L, K 2 HPO 4 2g / L, KH 2 PO 4 1g / L;

[0039]Seed pot medium formula (weight and volume percentage): 6% glycerin, 1% yeast extract, 0.5% tryptone, 0.3% dipotassium hydrogen phosphate, 0.3% potassium dihydrogen phosphate, and the balance is water;

[0040] Fermentation medium formula: corn steep liquor dry powder 25g / L, soybean powder 15g / L, K 2 HPO 4 3.5g / L, KH 2 PO 4 2.5g / L, glycerol 50g / L. Among them, corn steep liquor dry powder was purchased from Shandong Yuncheng Kangyuan Biotechnology Co., Ltd., soybean powder was purchased from Anyang Mantianxue Food Engineering Co., Ltd., and the trade name was deodorized sterilized soybean protein powder.

[0041] Inoculate the Propionibacterium acidogens preserved in con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com