Production process for special paper adhesive tape for gypsum board with paper surface

A paper-faced gypsum board and production process technology, applied in sustainable manufacturing/processing, adhesives, chemical industry, etc., can solve the problem that the thickness and strength of the tape cannot meet the requirements of use, the appearance quality of the finished product cannot meet the appearance requirements, and the wet water cannot be realized. sizing and other problems, to achieve the effect of good finished product quality, good printing quality and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

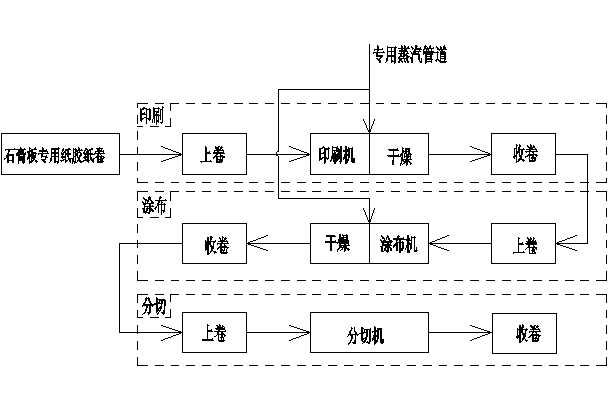

[0024] 1) Printing: Automatically rewind special tape rolls with a width of 700-720mm and a thickness of 0.08-0.09mm, and adopt an ultra-low cylinder tension detection closed-loop control system to quickly adjust the paper tension and control its accuracy at ±0.3mm. The printing machine is coated with special label ink, the printing error is controlled at 0.17-0.30mm, and the color thickness is controlled at 0.01-0.02mm. The obtained tape paper is put into a fully enclosed oven for external steam heating and drying. The drying temperature is controlled at 70-75°C. A good printing tape paper reaches a stable printing tension through the above-mentioned ultra-low cylinder tension detection closed-loop control system, and is then rewound;

[0025] 2) Coating: Roll up the tape paper roll that has been printed as described in step 1), and use water-soluble glue at 10-15g / m 2 For the tape paper completed in step 1), the coated tape paper roll is dried by hot air circulation, and the...

Embodiment 2

[0028] 1) Printing: Automatically rewind the special tape roll with a width of 720-750mm and a thickness of 0.08-0.09mm, and adopt an ultra-low cylinder tension detection closed-loop control system to quickly adjust the paper tension and control its accuracy at ±0.3mm, After the printing machine is coated with special label ink, the printing error is controlled at 0.17-0.30mm, and the color thickness is controlled at 0.01-0.02mm. The obtained tape paper is put into a fully enclosed oven for steam external heating and drying, and the drying temperature is controlled at 75-80°C. The dried printing tape paper reaches stable printing tension through the above-mentioned ultra-low cylinder tension detection closed-loop control system, and is rewound;

[0029] 2) Coating: roll up the tape paper roll that has been printed as described in step 1), and use water-soluble glue at 15-20g / m 2 For the tape paper completed in step 1), the coated tape paper roll is dried by hot air circulation...

Embodiment 3

[0032] 1) Printing: Automatically rewind special tape paper rolls with a width of 750-800mm and a thickness of 0.09-0.10mm, and adopt an ultra-low cylinder tension detection closed-loop control system to quickly adjust the paper tension and control its accuracy at ±0.3mm, After the printing machine is coated with special label ink, the printing error is controlled at 0.17-0.30mm, and the color thickness is controlled at 0.01-0.02mm. The obtained tape paper is put into a fully enclosed oven for steam external heating and drying, and the drying temperature is controlled at 80-85°C. The dried printing tape paper reaches stable printing tension through the above-mentioned ultra-low cylinder tension detection closed-loop control system, and is rewound;

[0033] 2) Coating: roll up the printed tape paper described in step 1), and use water-soluble glue at 20-25g / m 2 For the tape paper completed in step 1), the coated tape paper roll is dried by hot air circulation, and the drying temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com