High-dielectric constant low-loss metal/polymer composite and preparation method thereof

A high dielectric constant and composite material technology, applied in the field of dielectric composite material preparation, can solve the problems of high loss and impracticality, and achieve the effects of stable performance, low cost, good frequency and temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

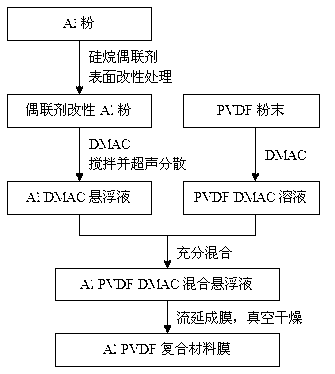

Method used

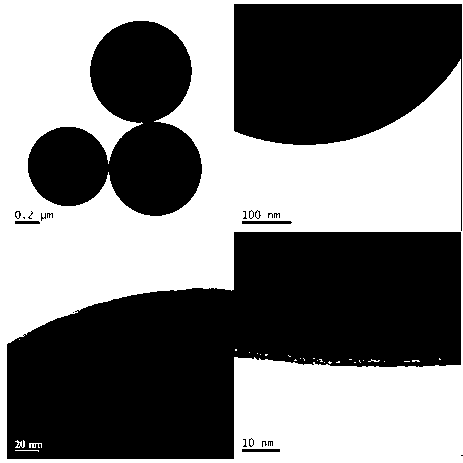

Image

Examples

Embodiment 1

[0022] (1) At room temperature, 50 g of Al powder was ultrasonically dispersed and stirred to form a suspension in absolute ethanol, and then 0.5 g of coupling agent (γ-aminopropyltriethoxysilane) was added and stirred continuously for 10~ 30 minutes; then add deionized water, ultrasonically disperse and stir at 40-60°C for 15-60 minutes; centrifuge the powder, wash with absolute ethanol for 1-3 times, and then vacuum dry at 60-120°C for 2 ~5 hours, use after natural cooling to room temperature;

[0023] (2) Weigh 0.8333 g of the Al powder obtained by modifying the silane coupling agent in step (1); make its volume percentage in the composite material 10%, and weigh it according to the Al / DMAC weight ratio of 1 / 1 Corresponding to DMAC, ultrasonically disperse Al powder in DMAC to obtain dispersion a; weigh 4.9166 g of PVDF powder according to the polymer matrix PVDF volume percentage of 90%, and weigh DMAC according to the PVDF / DMAC weight ratio of 1 / 7, Dissolve PVDF in DMAC ...

Embodiment 2

[0026] (1) The surface treatment process of Al powder is with embodiment 1;

[0027] (2) Weigh 1.9212 g of the Al powder obtained by modifying the silane coupling agent in step (1); make its volume percentage in the composite material 20%, and weigh it according to the Al / DMAC weight ratio of 1 / 1 Corresponding to DMAC, ultrasonically disperse Al powder in DMAC to obtain dispersion a; weigh 5.0382 g of PVDF powder according to the polymer matrix PVDF volume percentage of 80%, and weigh DMAC according to the PVDF / DMAC weight ratio of 1 / 9, Dissolve PVDF in DMAC at 50°C, and cool to room temperature to obtain solution b; then mix dispersion a and solution b, and after ultrasonic dispersion for 10-30 minutes and magnetic stirring for 15-60 minutes, the mixture of Al and PVDF is obtained. Mix the suspension; cast the mixed suspension on a clean glass plate to form a film, and dry it in vacuum at 80 °C for 2 hours to obtain an Al / PVDF composite film.

[0028] (3) The dielectric consta...

Embodiment 3

[0030] (1) The surface treatment process of Al powder is the same as embodiment 1;

[0031] (2) Weigh 3.5103 g of the Al powder obtained by modifying the silane coupling agent in step (1); make its volume percentage in the composite material 30%, and weigh it according to the Al / DMAC weight ratio of 1 / 2 Corresponding to DMAC, ultrasonically disperse Al powder in DMAC to obtain dispersion a; weigh 5.3701 g of PVDF powder according to the polymer matrix PVDF volume percentage of 70%, and weigh DMAC according to the PVDF / DMAC weight ratio of 1 / 5, Dissolve PVDF in DMAC at 50°C, and cool to room temperature to obtain solution b; then mix dispersion a and solution b, and after ultrasonic dispersion for 10-30 minutes and magnetic stirring for 15-60 minutes, the mixture of Al and PVDF is obtained. Mix the suspension; cast the mixed suspension on a clean glass plate to form a film, and dry it in vacuum at 80 °C for 2 hours to obtain an Al / PVDF composite film.

[0032] (3) The dielectr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com