Quick-drying weather-resistant high-solid-content acrylic resin and preparation method thereof

An acrylic resin, weather-resistant technology, used in coatings and other directions, can solve the problems of unsatisfactory drying speed and aging resistance, and achieve the effects of excellent aging resistance, excellent aging resistance and high solid content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

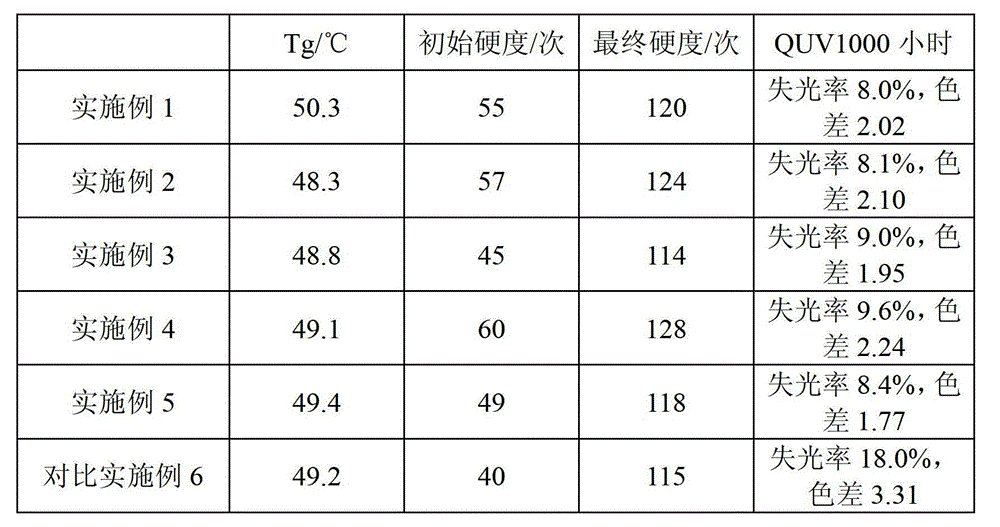

Examples

Embodiment 1

[0026] First, prepare the Macro monomer: weigh 90g of methyl methacrylate (MMA), 120g of hydroxyethyl methacrylate (HEMA), 140g of butyl methacrylate (BMA), butyl acetate 150g, 2.05g of azobisisobutyronitrile (AIBN), 100mg of dihydrated bis(difluoride borobenzenedione oxime) cobaltate (II) salt (COPhBF), mix them uniformly and add them into the reaction flask, Heat and stir at 75°C under nitrogen atmosphere, and react for 5 hours. The solid content of the obtained product is 68.4%, the GPC result Mn=1581, Mw / Mn=1.56.

[0027] Next, 150 g of trimethylbenzene and 50 g of glycidyl tertiary carbonate were added to a four-necked flask equipped with stirring and a condenser, stirred at a low speed and nitrogen was introduced, and the temperature was raised to 150°C. A mixed solution consisting of 500 g of a comonomer and 68 g of an initiator solution was uniformly added dropwise over 4 hours. Among them, the comonomers include: butyl methacrylate (BMA) 100g, isobornyl methacrylate...

Embodiment 2

[0031] The preparation of the macromonomer (Macro monomer) of embodiment 2 is identical with embodiment 1, and its difference only lies in the following steps:

[0032] Add 150 g of trimethylbenzene and 50 g of glycidyl tertiary carbonic acid ester (Cardura E10P) into a four-neck flask with a stirring and condenser, stir at a low speed and blow in nitrogen, and raise the temperature to 150°C. A mixed solution consisting of 500 g of a comonomer and 68 g of an initiator solution was uniformly added dropwise over 4 hours. Among them, the comonomers include: butyl methacrylate (BMA) 125g, isobornyl methacrylate (IBOMA) 75g, styrene (ST) 82g, hydroxyethyl methacrylate (HEMA) 152g, acrylic acid (AA ) 16g and macromonomer 50g; the initiator solution includes: 50g of butyl acetate, 9g of tert-butyl peroxybenzoate and 9g of di-tert-amyl peroxide.

[0033] After the dropwise addition was completed, it was incubated at a temperature of 150° C. for 30 minutes, then added an initiator solut...

Embodiment 3

[0036] The preparation of the macromonomer (Macro monomer) of embodiment 3 is identical with embodiment 1, and its difference only lies in the following steps:

[0037] Add 165 g of trimethylbenzene and 75 g of glycidyl tertiary carbonic acid ester (Cardura E10P) into a four-necked flask with a stirring and condenser, stir at a low speed and blow in nitrogen, and raise the temperature to 150°C. A mixed solution consisting of 500 g of a comonomer and 68 g of an initiator solution was uniformly added dropwise over 4 hours. Among them, the comonomer includes: methyl methacrylate (MMA) 60g, butyl methacrylate (BMA) 83g, isobornyl methacrylate (IBOMA) 50g, styrene (ST) 82g, methacrylate hydroxy Ethyl ester (HEMA) 152g, acrylic acid (AA) 23.2g and macromonomer 50g; the initiator solution includes: butyl acetate 50g, tert-butyl peroxybenzoate 9g and di-tert-amyl peroxide 9g.

[0038] After the dropwise addition was completed, it was incubated at a temperature of 150° C. for 30 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com