Preparation method and application of fatty acid monoglyceride

A monoglyceride and fatty acid technology, applied in the field of chemical synthesis, can solve the problems of troublesome post-processing of boric acid, high reaction temperature, long reaction time, etc., and achieve the effects of short reaction time, low reaction temperature and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

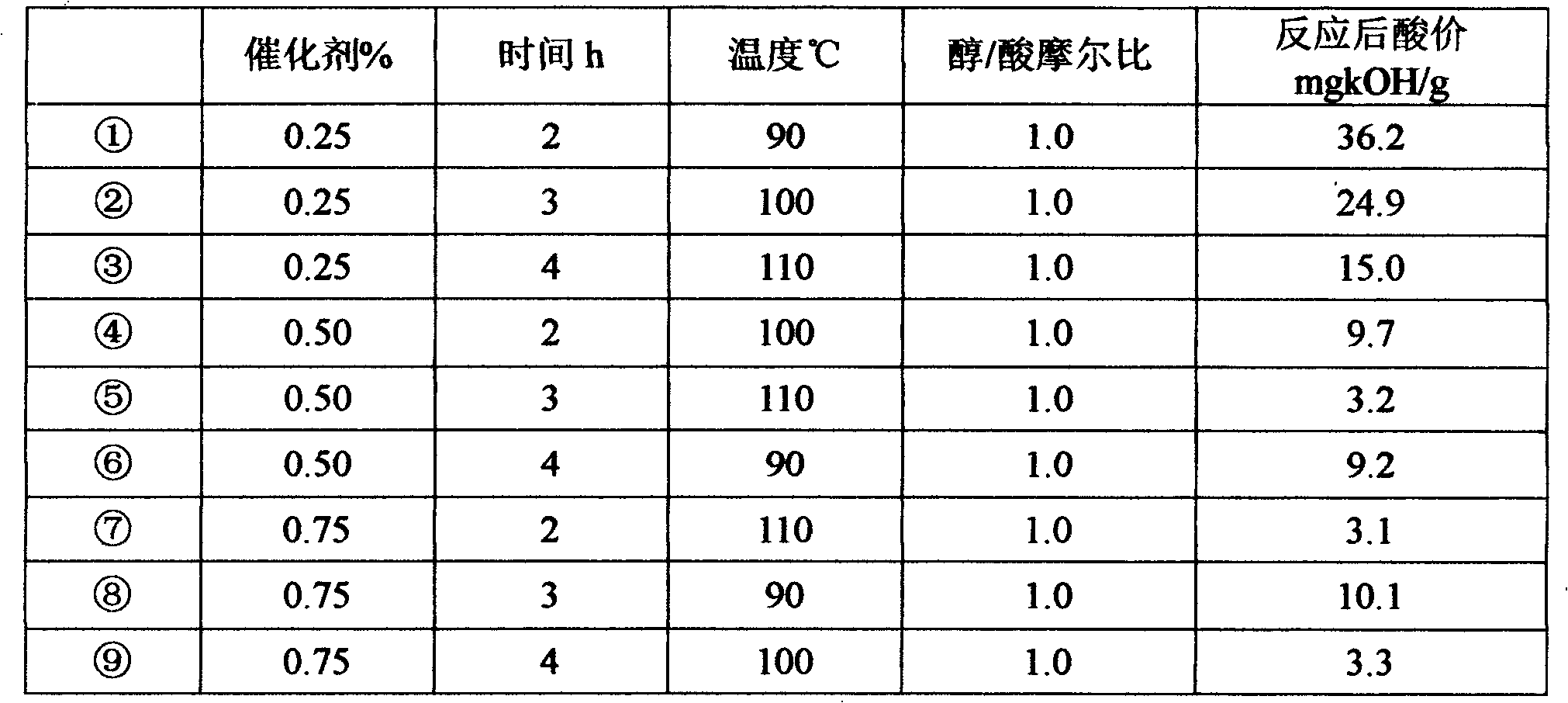

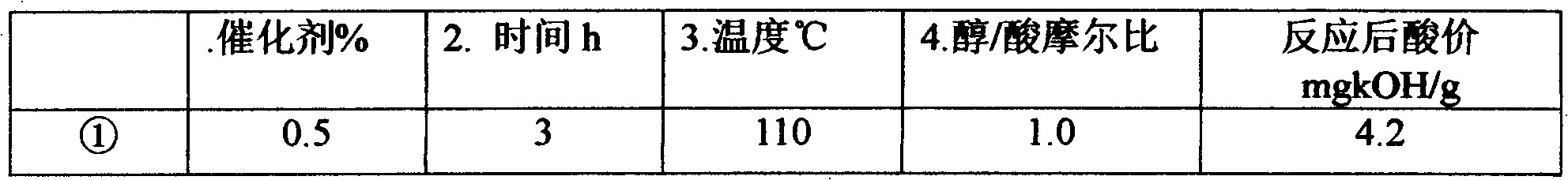

Embodiment 1

[0024] Weigh 92g of glycerol and 200g of lauric acid into a flat-bottomed flask, stir evenly, add 0.73g of N-alkylpyrrolidone group toluenesulfonic acid ionic liquid catalyst, stir, heat, control the temperature to 90°C, and react for 2 hours, namely The final product was obtained with an acid value of 36.2 mgKOH / g.

Embodiment 2

[0026] Weigh 92g of glycerol and 200g of lauric acid into a flat-bottomed flask, stir evenly, add 0.73g of N-alkylpyrrolidone group toluenesulfonic acid ionic liquid catalyst, stir, heat, control the temperature to 100°C, and react for 3 hours, namely The final product was obtained with an acid value of 24.9 mgKOH / g.

Embodiment 3

[0028] Weigh 92g of glycerol and 200g of lauric acid into a flat-bottomed flask, stir evenly, add 0.73g of N-alkylpyrrolidone group toluenesulfonic acid ionic liquid catalyst, stir, heat, control the temperature to 110°C, and react for 4 hours, namely The final product was obtained with an acid value of 15.0 mgKOH / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com