Normal-temperature starting domestication method for anaerobic ammoxidation reactor with low-dissolved-oxygen inflow water

An anammox and reactor technology, applied in anaerobic digestion treatment and other directions, can solve the problems of slow growth of anammox bacteria, large energy consumption, low cell yield, etc., and achieve stable operation of the reactor system and reduce The effect of high operating cost and denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0019] Specific embodiment one: In this embodiment, the start-up and domestication method of the anaerobic ammonium oxidation reactor with low dissolved oxygen inflow at normal temperature is realized according to the following steps:

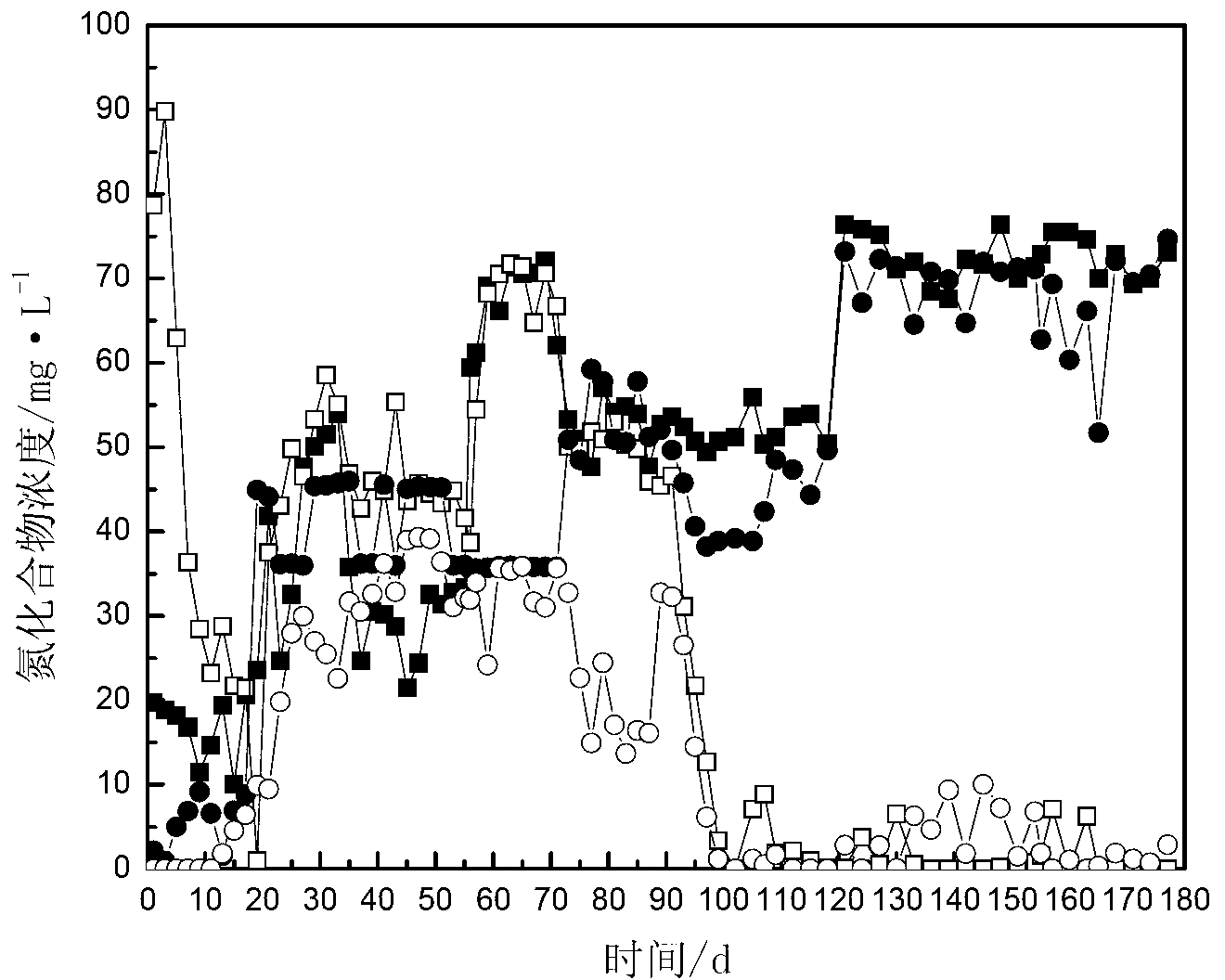

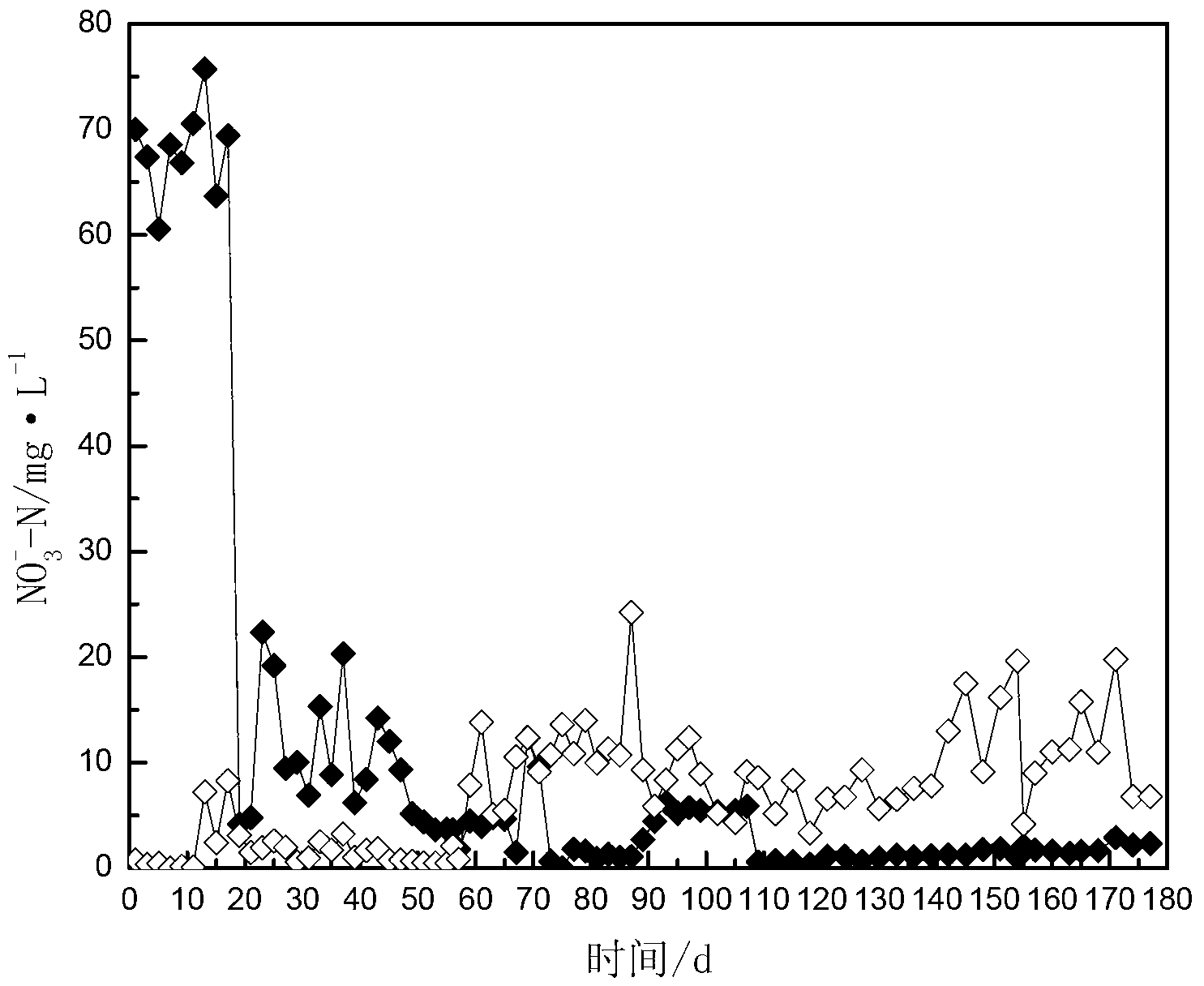

[0020] 1. Cultivation of denitrification biofilm: In the anaerobic ammonium oxidation reactor filled with ceramsite filler, the denitrification sludge from the secondary sedimentation tank of Harbin Taiping Sewage Treatment Plant was used as the seed sludge, and the influent NO 3 - -The concentration of N is 60~75mg / L, and the denitrification biofilm is cultivated at the temperature of 21 ℃. After 20 days, the grayish yellow denitrification biofilm is attached to the ceramsite filler;

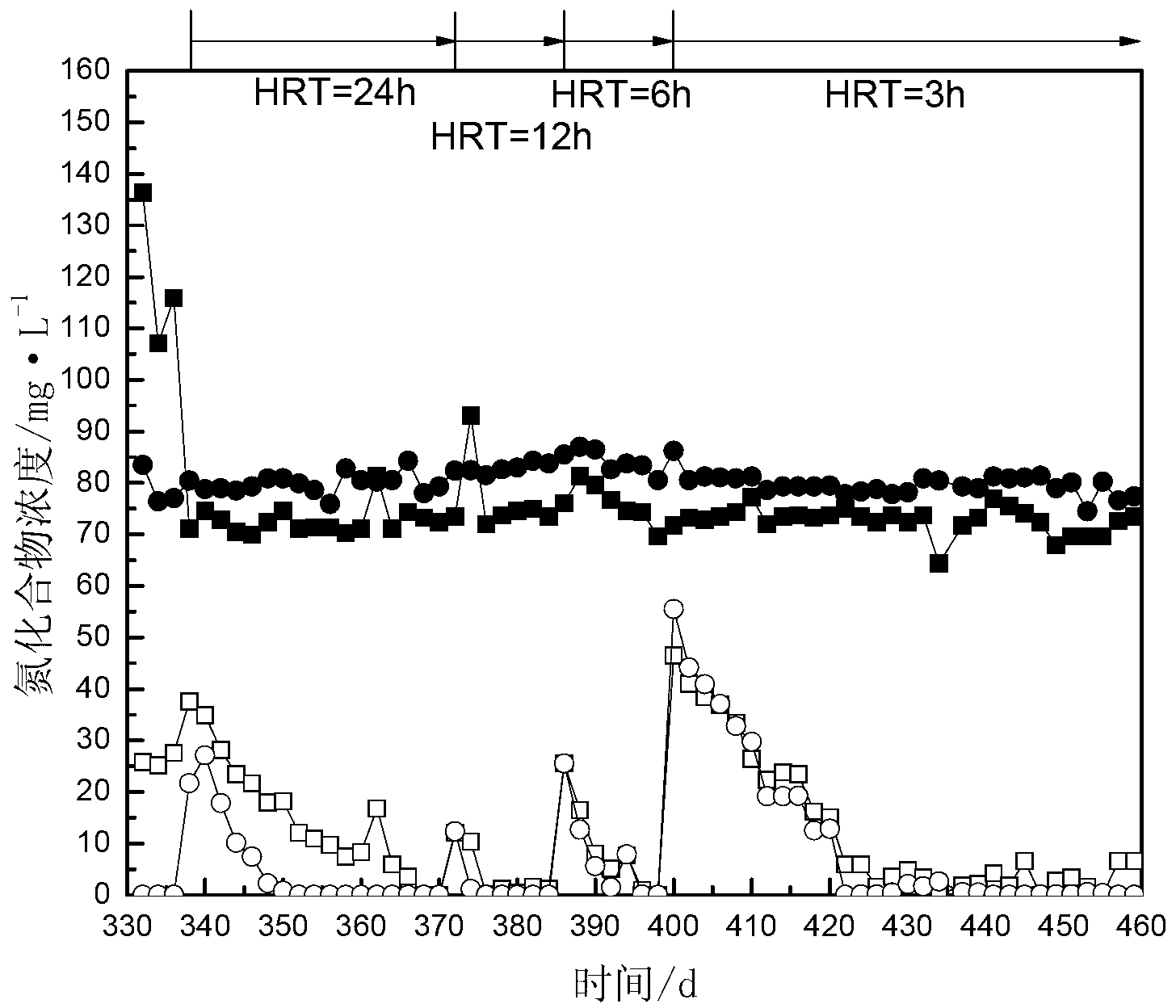

[0021] 2. Start-up of the anaerobic ammonium oxidation reactor: use domestic sewage and tap water from the sewer of the family area of the second district of Harbin Institute of Technology as the influent water, and control the NH 4 + -N and NO 2 - The rat...

specific Embodiment approach 2

[0027] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the height of the ceramsite filler added in the anammox reactor in Step 1 is 0.45-0.5m. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0028] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 is that the density of ceramsite filler in step 1 is 1.00~1.50g / cm, the porosity is >30%, and the specific surface area is 1.8~3.0cm 2 / g. Other steps and parameters are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com