Anaerobic ammonia oxidizing bacteria bioreactor

A bioreactor and anammox technology, applied in the field of anammox bacterial bioreactor, can solve the problems of inconspicuous partition of three-phase separation chamber, insufficient sludge retention capacity, complex reactor structure, etc. The effect of faster sludge proliferation, faster sludge growth, and reduced sludge loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

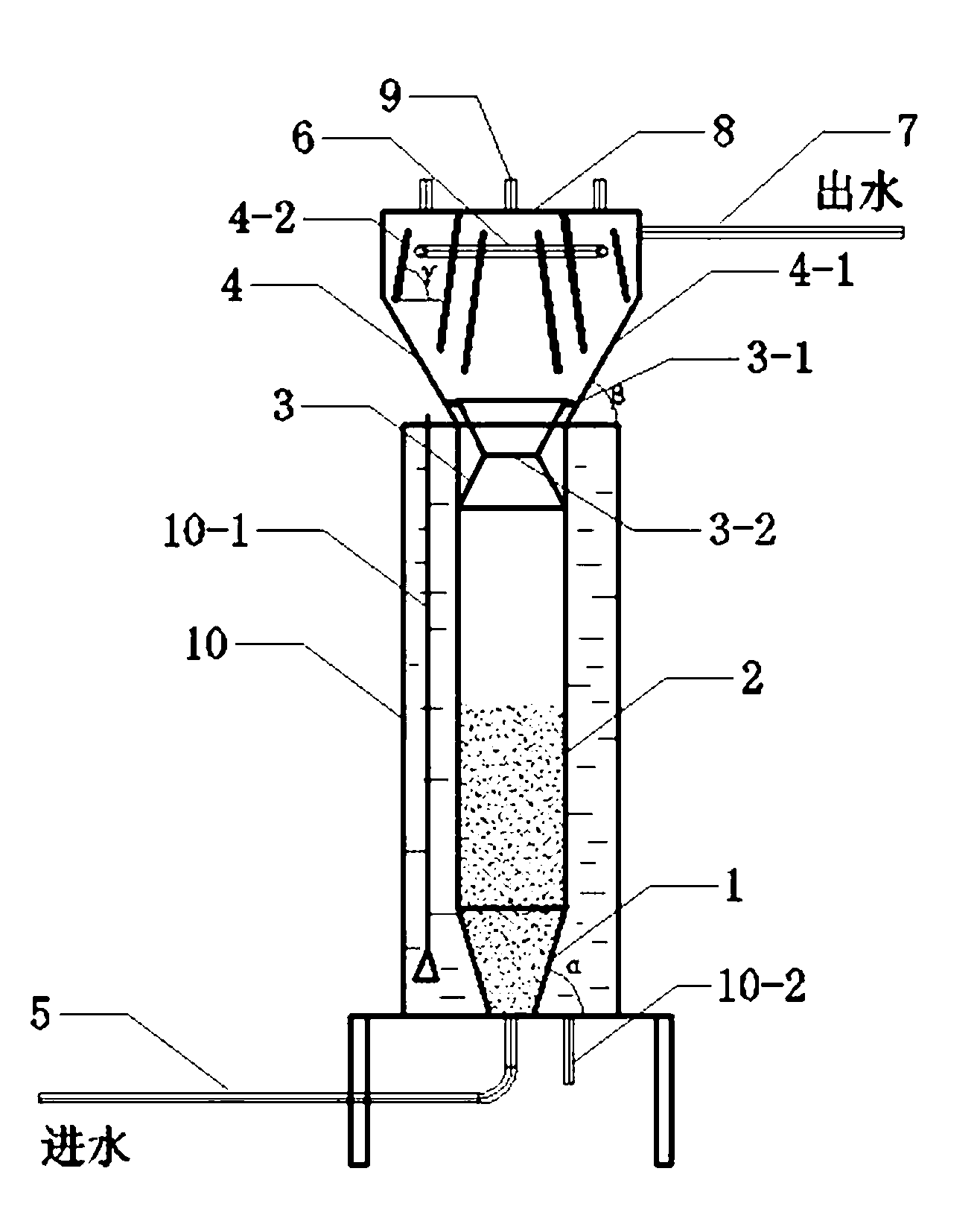

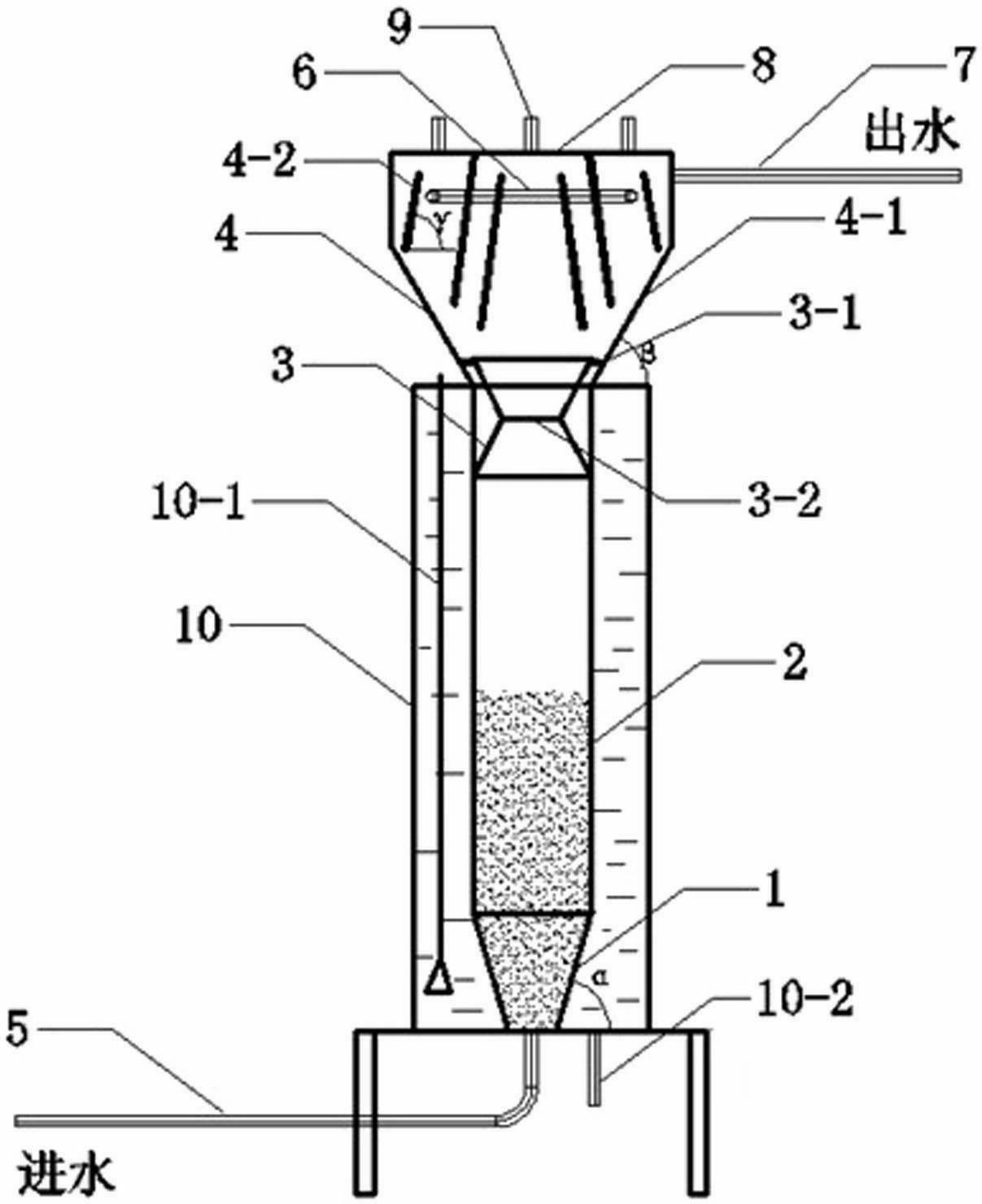

[0020] refer to figure 1 , the present invention has distinct four partitions. The lower part of the reactor is a tetrahedral pyramid water inlet buffer zone 1, and a water inlet pipe 5 is provided at the bottom of the buffer zone 1, and the buffer zone 1 is followed by a square upflow reaction chamber 2, a first-stage three-phase separation device 3, and a second-stage three-phase separation device. The first-stage three-phase separation device 4 is provided with a water outlet pipe 7 on the upper part of the second-stage three-phase separation device 4, and a sealing cover 8 is installed on the top and an air outlet 9 is provided. Anammox bacteria exist in the upflow reaction chamber 2 in the form of granular sludge. A water bath insulation jacket 10 is provided outside the main body of the reactor, its length and width are 1.5-2 times that of the upflow reaction chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com