Tube-type reflux cooler

A cooler and sleeve-type technology, applied in the field of atmosphere sampling devices, can solve problems such as complex structural design, affecting measurement accuracy, troublesome manual maintenance, etc., achieve wide adaptability and compatibility, avoid safety hazards, and have good separation effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

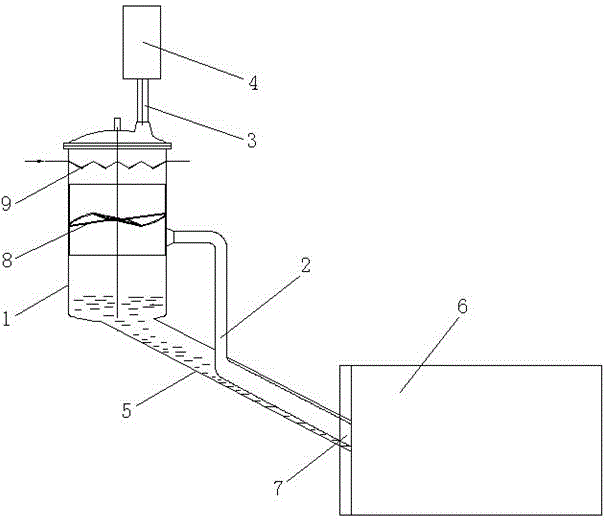

[0019] Such as figure 1 As shown, a sleeve-type reflux cooler includes a cylindrical shell 1 and an atmosphere cooling mechanism. 1. The top is connected to the atmosphere detector 4 through the gas outlet pipeline 3, and the drain port is connected to the detection port 7 of the annealing furnace 6 through the return pipe 5. The lower part of the shell 1 is provided with an atmosphere inlet, and the atmosphere inlet is sampled through the sample gas. The pipeline 2 is connected to the detection port 7 of the annealing furnace 6, and a section of the sample gas sampling pipeline 2 close to the annealing furnace 6 is set in the return pipe 5, and the height of the drain port is higher than the detection port 7 of the annealing furnace 6, Usually, the angle between the length direction of the return pipe 5 and the bottom surface of the housing 1 is 40° to 80° to ensure that the condensed water in the return pipe 5 can flow back into the annealing furnace 6 by itself. In this emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com