Embedded electric-steamer steam discharge system

A technology of exhaust system and electric steamer, which is applied to steam cooking utensils, kitchen utensils, household utensils, etc. It can solve the problems of easy scald users, poor sealing of hoses, and inconvenient installation, and achieve good safety and sealing effect Good, easy to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

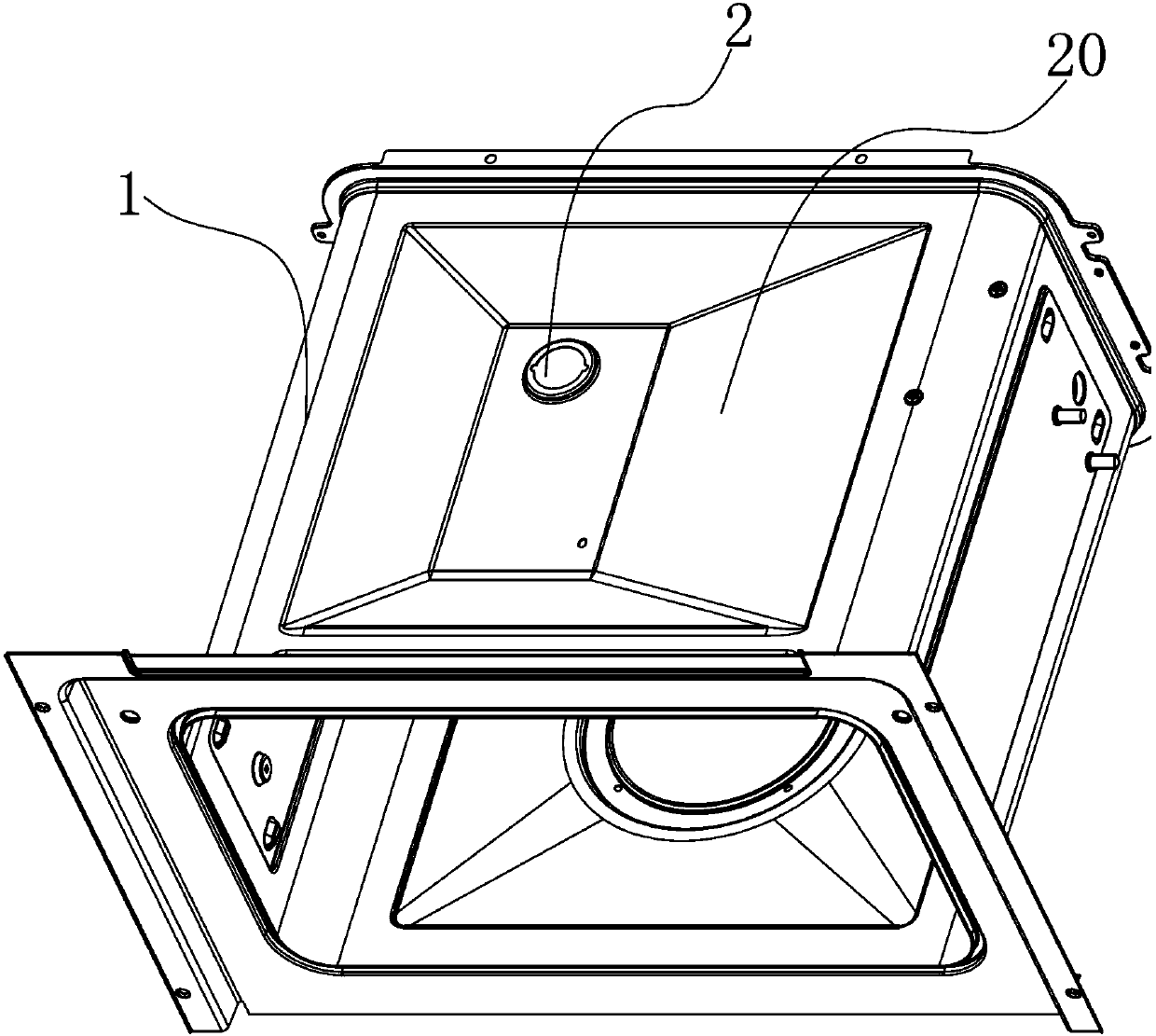

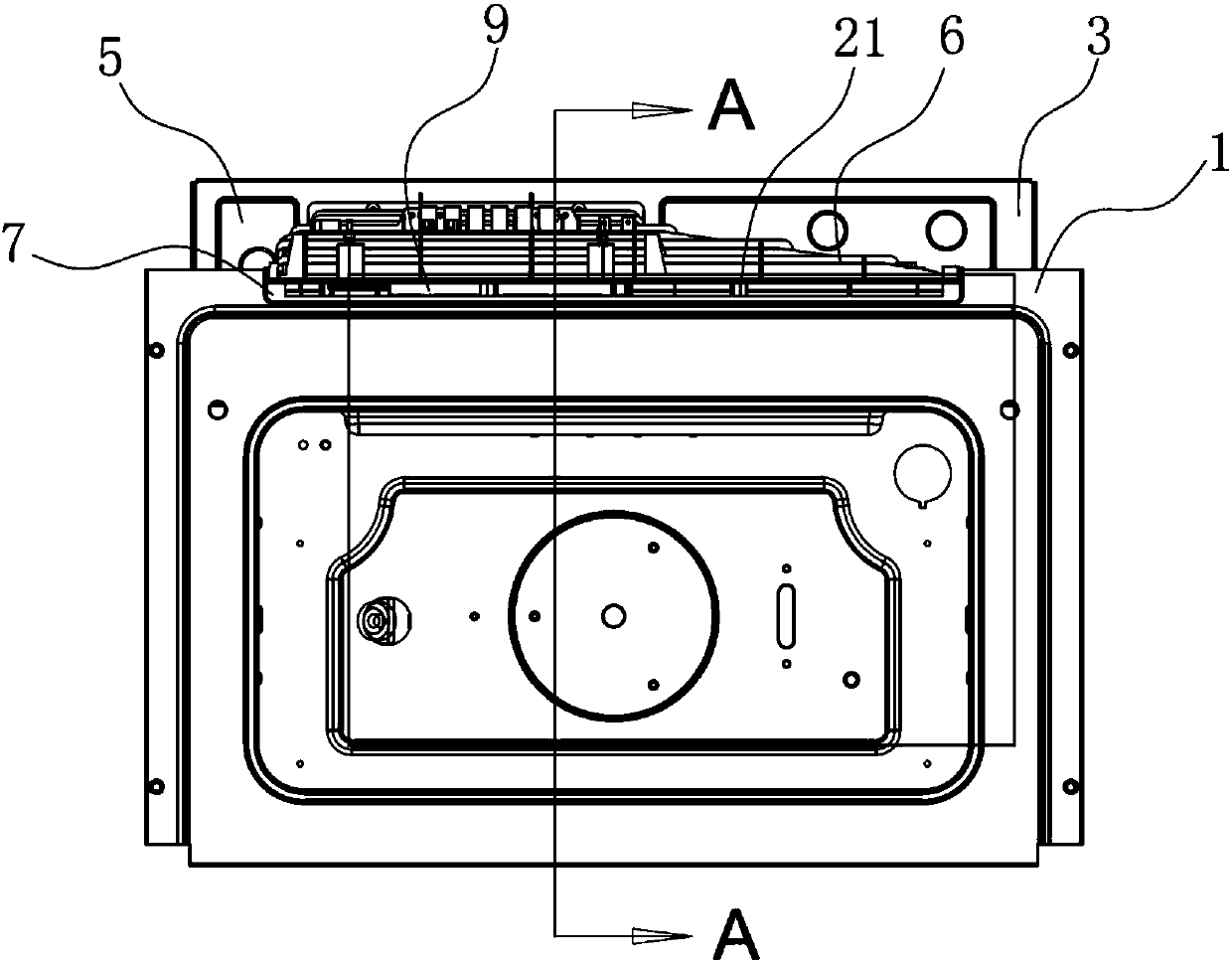

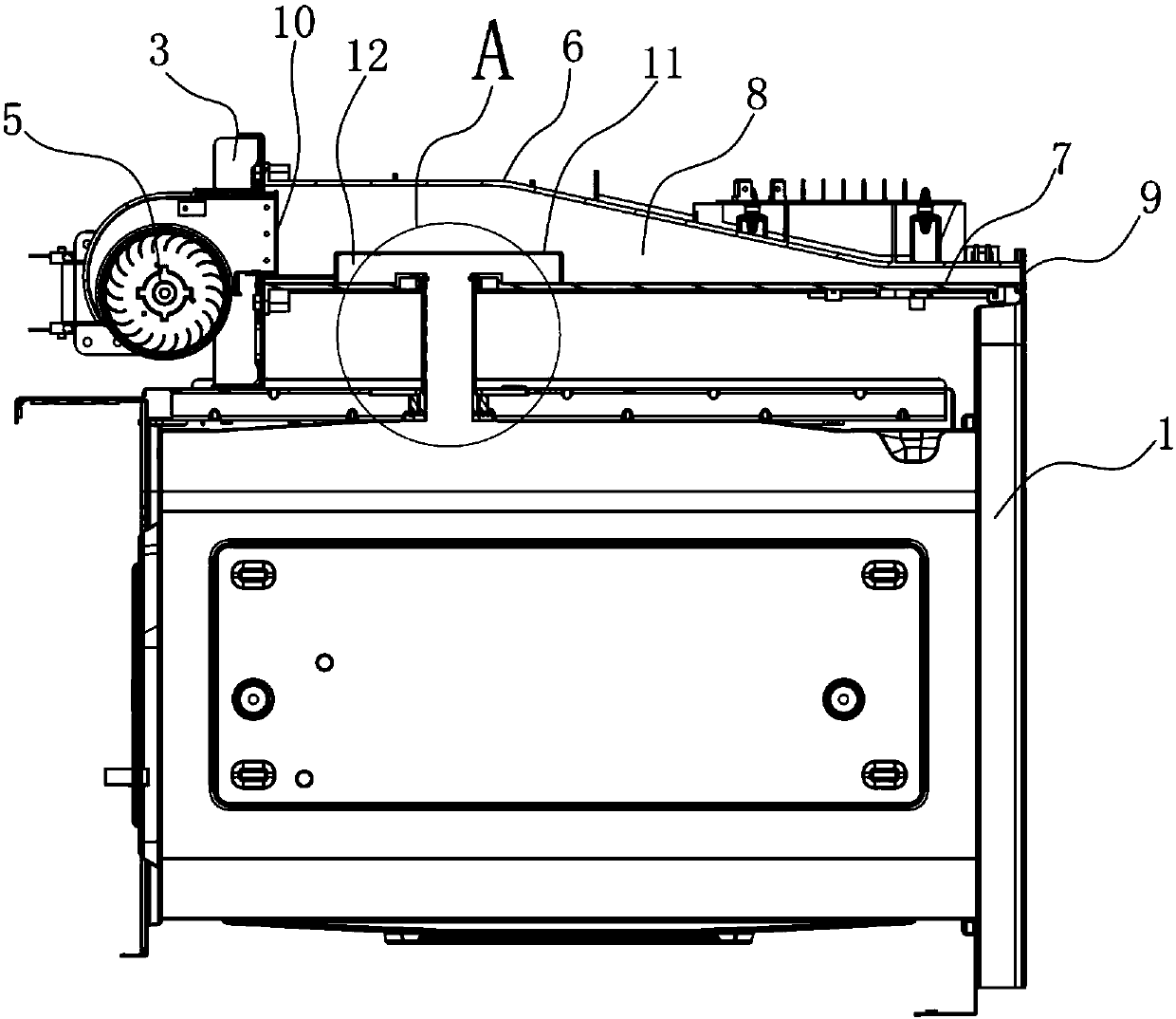

[0033] Such as figure 1 , figure 2 An embedded electric steamer exhaust system shown includes an electric steamer liner 1, a heat shield 3 fixed on the electric steamer liner, an air duct 4, an exhaust assembly and a cooling fan 5, and the exhaust The assembly includes an exhaust hood 6 and a cover bottom plate 7 that is fixed on the inner container of the electric steamer and is compatible with the exhaust hood (see image 3 , Figure 4 , Figure 6 ), the exhaust hood and the bottom plate of the cover are detachably connected by buckles, the top surface of the electric steamer liner is recessed to form a mounting groove 20, and there is a steam outlet 2 at the bottom of the mounting groove, and the exhaust hood and the bottom plate of the cover are close to the heat insulation One end of the plate is fixedly connected with the heat insula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com