Water-phase preparation method of near-infrared luminescent silver sulfide quantum dot

A water-phase preparation, quantum dot technology, applied in chemical instruments and methods, luminescent materials, silver compounds, etc., can solve the problems of quantum dot size increase, luminescence intensity weakening, biological tissue damage, etc., to achieve good dispersibility, good Biocompatibility, mild reaction conditions effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

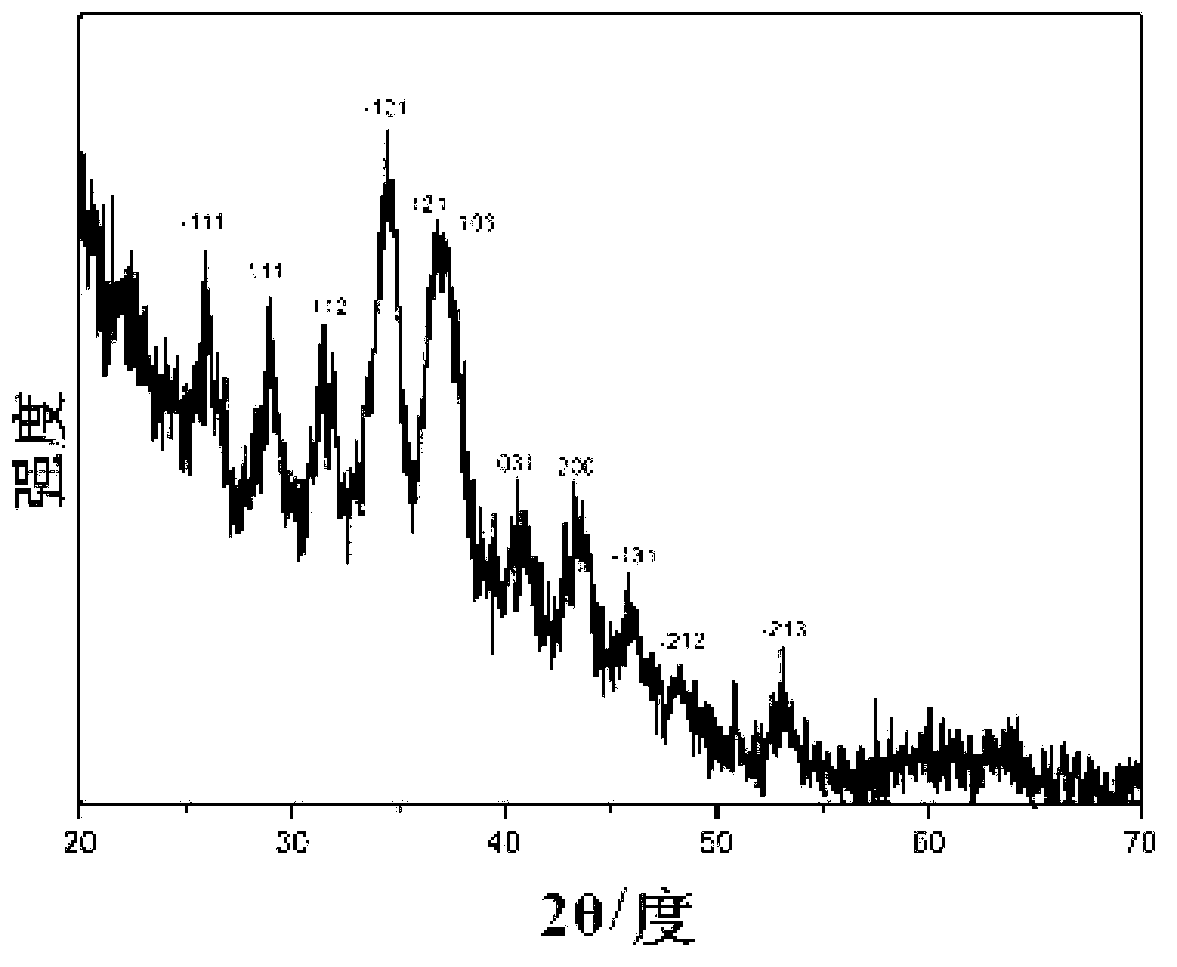

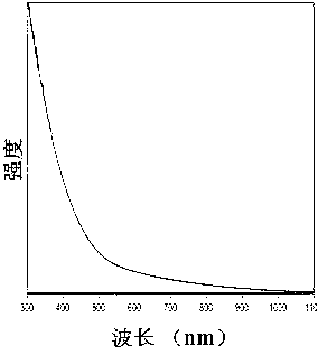

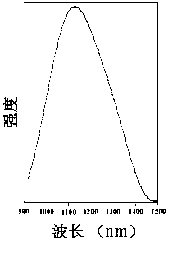

Image

Examples

Embodiment 1

[0034] 1. Prepare 50ml of 0.5% bovine serum albumin solution with double distilled water; add silver nitrate (1mmol / L, 25ml) dropwise to the bovine serum albumin solution with a stirring speed of 30 rpm, 25 ℃ overnight in the dark to obtain reaction solution 1; sodium sulfide (3mmol / L, 25ml) was placed in the syringe on the syringe pump, and added dropwise at a speed of 480 μL / min to the reaction solution with a stirring speed of 50 rpm 1. After the dropwise addition, the reaction continued for 10 minutes. After the reaction was completed, the reaction solution 2 was obtained; put 50 mL of the reaction solution 2 into a semi-permeable membrane dialysis bag soaked in ultrapure water (MWCO (molecular weight cut-off) = 100KDs), two After the end is sealed, dialyze in 1 L of distilled water to remove ions that have not participated in the reaction; the distilled water is replaced every 6 hours, and dialyzed for 2 days to obtain the product solution; the above operations are all...

Embodiment 2

[0039] 1. Use double-distilled water to prepare 50ml of bovine serum albumin solution with a concentration of 1% by mass; add silver nitrate (1mmol / L, 25ml) dropwise to the bovine serum albumin solution with a stirring speed of 30 rpm, React overnight at 25°C in the dark to obtain reaction solution 1; thioacetamide (0.3mmol / L, 25ml) was placed in the syringe on the syringe pump, and added dropwise at a speed of 100 μL / min until the stirring speed was 50 rpm Minutes of reaction solution 1, after the dropwise addition, the reaction continued for 10 minutes, and the reaction was completed to obtain reaction solution 2; 50 mL of reaction solution 2 was placed in a semi-permeable membrane dialysis bag soaked in ultrapure water (MWCO (molecular weight cut-off) = 100KDs), sealed at both ends, dialyzed in 1 L of distilled water to remove unreacted ions; the distilled water was changed every 6 hours, and dialyzed for 2 days to obtain the product solution; the above operations were a...

Embodiment 3

[0043]1. Use double-distilled water to prepare 50ml of bovine serum albumin solution with a mass ratio concentration of 2%; silver nitrate (1mmol / L, 25ml) is added dropwise to the bovine serum albumin solution at a stirring speed of 30 rpm, 30 ℃ overnight in the dark to obtain reaction solution 1; sodium sulfide (3mmol / L, 25ml) was placed in the syringe on the syringe pump, and added dropwise at a speed of 100 μL / min to the reaction solution with a stirring speed of 50 rpm 1. After the dropwise addition, the temperature of the reaction was raised to 70°C and kept for 2 hours. After the reaction was completed, the reaction solution 2 was obtained; after the reaction solution was cooled to room temperature, 50 mL of the reaction solution 2 was placed in a semi-permeable membrane soaked in ultrapure water In a dialysis bag (MWCO (molecular weight cut-off) = 100KDs), after both ends are sealed, dialyze in 1 L of distilled water to remove ions that have not participated in the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com